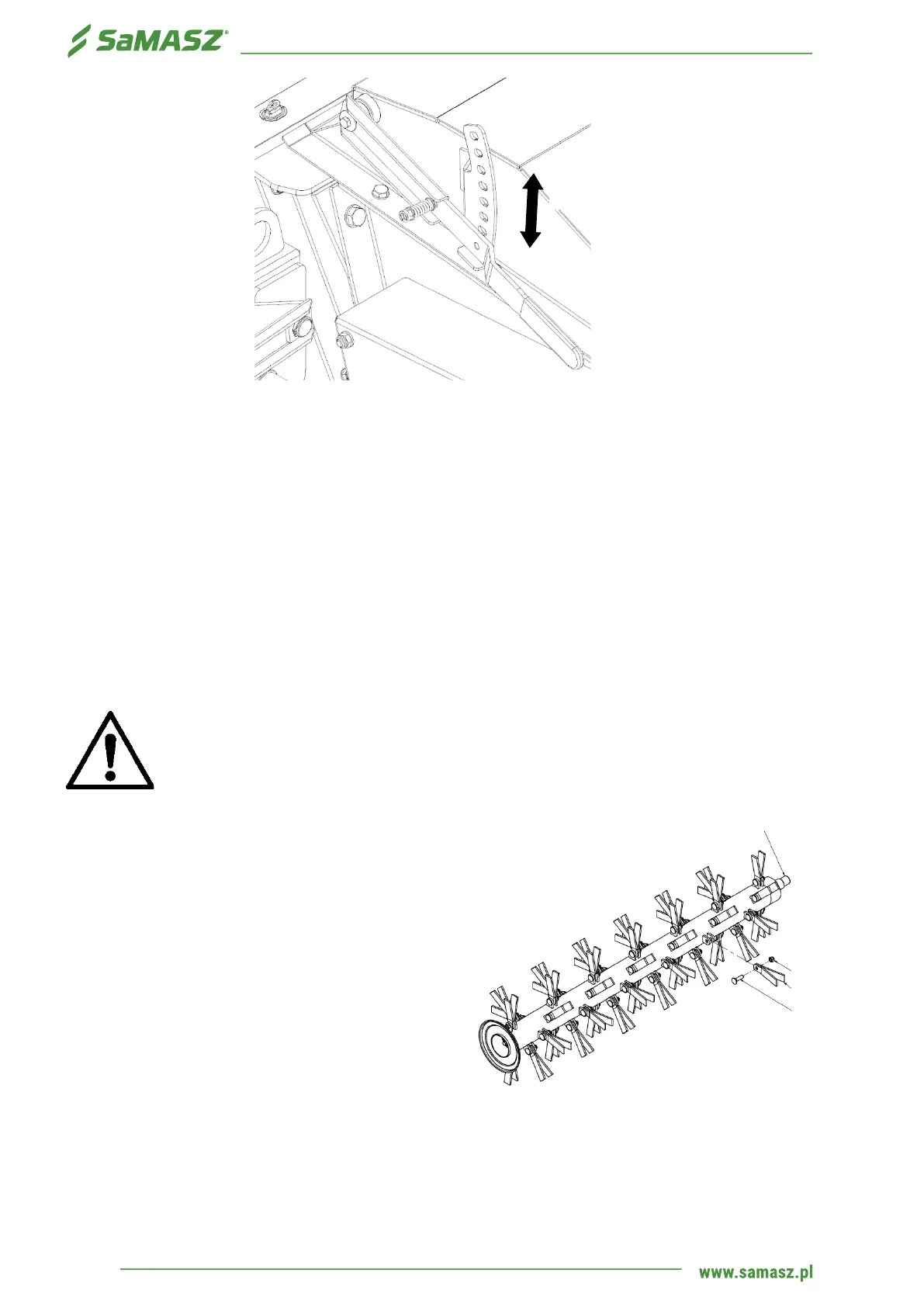

Fig. 31. Adjusting tine conditioner’s mask

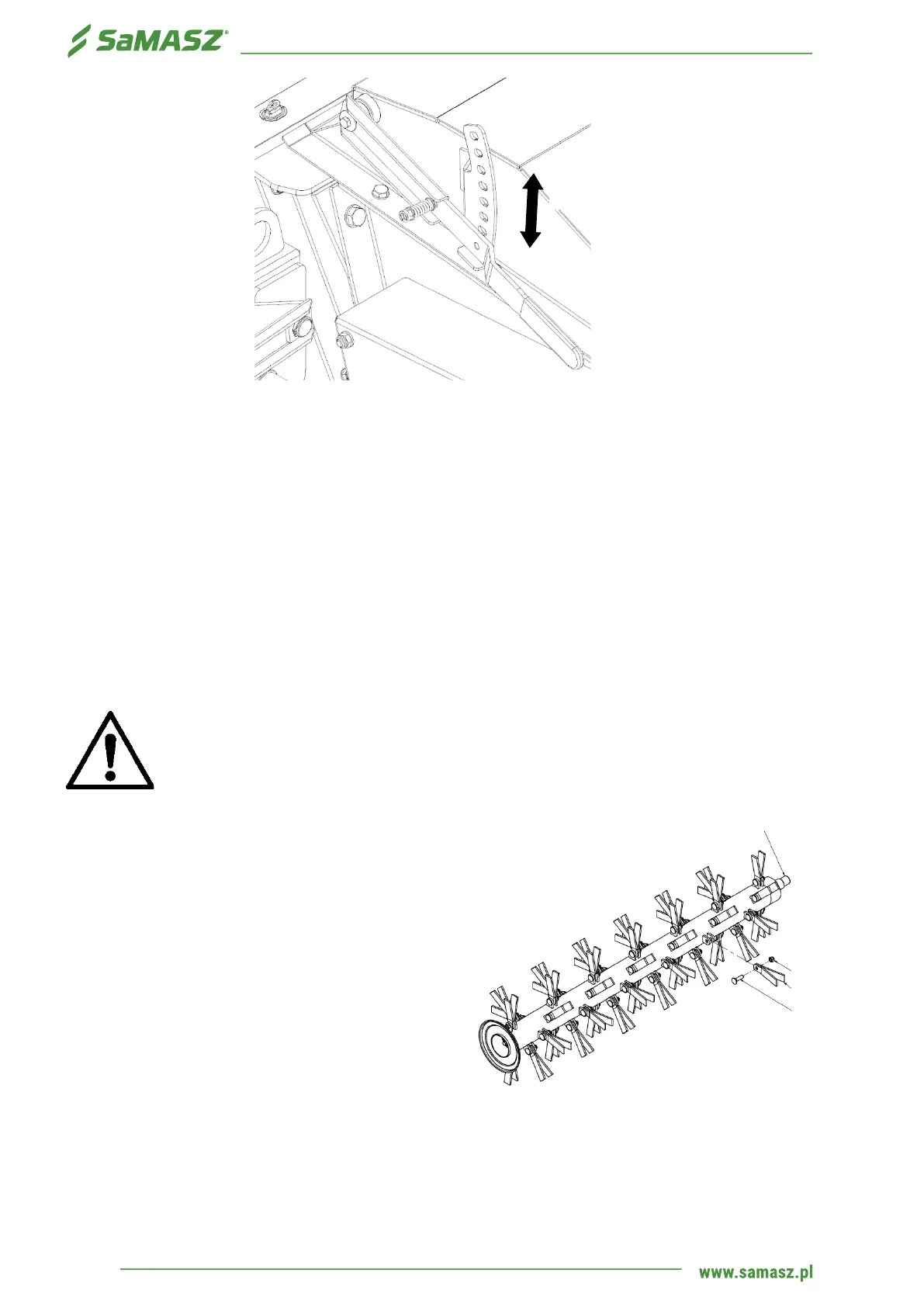

6.9. Replacing the conditioner’s tines

(Models: KDT 220 S KDT 260 S (SL))

Worn tines must be immediately replaced with new ones. Each time, before the work begins,

check the conditioner’s tines along with the bolts on which the tines are mounted and tines’ holders.

Bear in mind, that flails should be replaced in pairs (opposite) featuring the same weight in

order to keep shaft well balanced. Not keeping the shaft well balanced may lead to premature wearing

of bearings as well as the shaft itself.

Replacement of flails 3 consists in unscrewing of nuts 2, removing bolts 4 and mounting brand

new flails 3 (Fig. 32).

CAUTION:

In order to tighten screw connection use special purpose bolt M16x60 oc. kl.

10.9 and self-protected nut M16 oc. kl. 8; torque down until tight.

1. Scarfier shaft

2. Self-locking nut M16 oc. kl. 8

3. Flail

4. Bolt M16x60 kl. 10.9

Fig. 32a. Replacement of flails in conditioner roller

Loading...

Loading...