3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive from

tractor’s rpm is transmitted through intersecting axis gear (3) on the cutterbar (4). On the cutterbar,

there are discs with two knives each. Apart from that, drive from tractor’s rpm through V-belt drive (8)

and PTO shaft (9) is transmitted to tine conditioner (7). Hydraulic cylinder (2) is used to adjust

the mower to working position. It is supplied from outer hydraulics of the tractor. Main frame, on which

the cutterbar (4) is situated, is supported by the springs (2). Swath guides (5) are mounted on the safety

curtain (6).

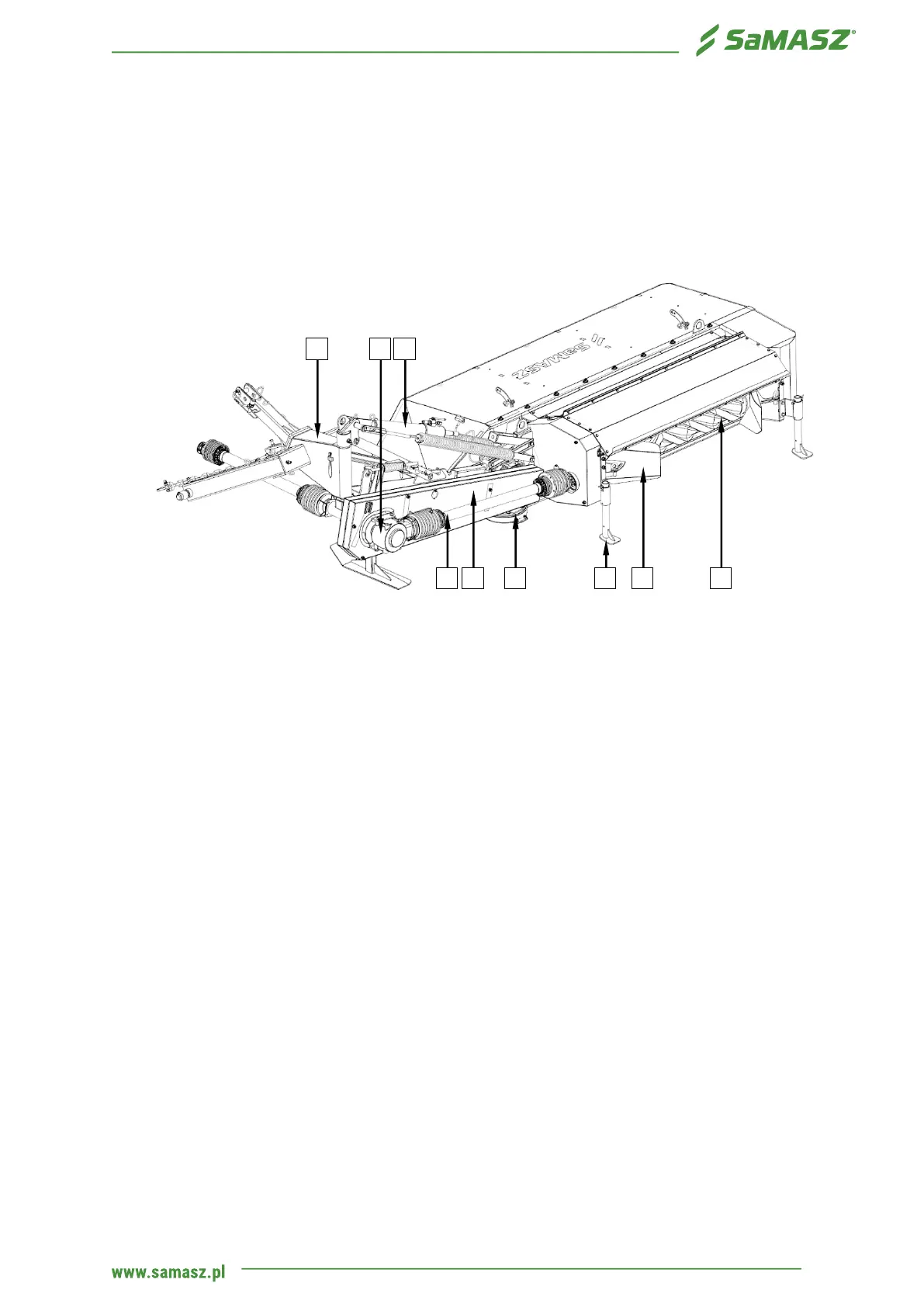

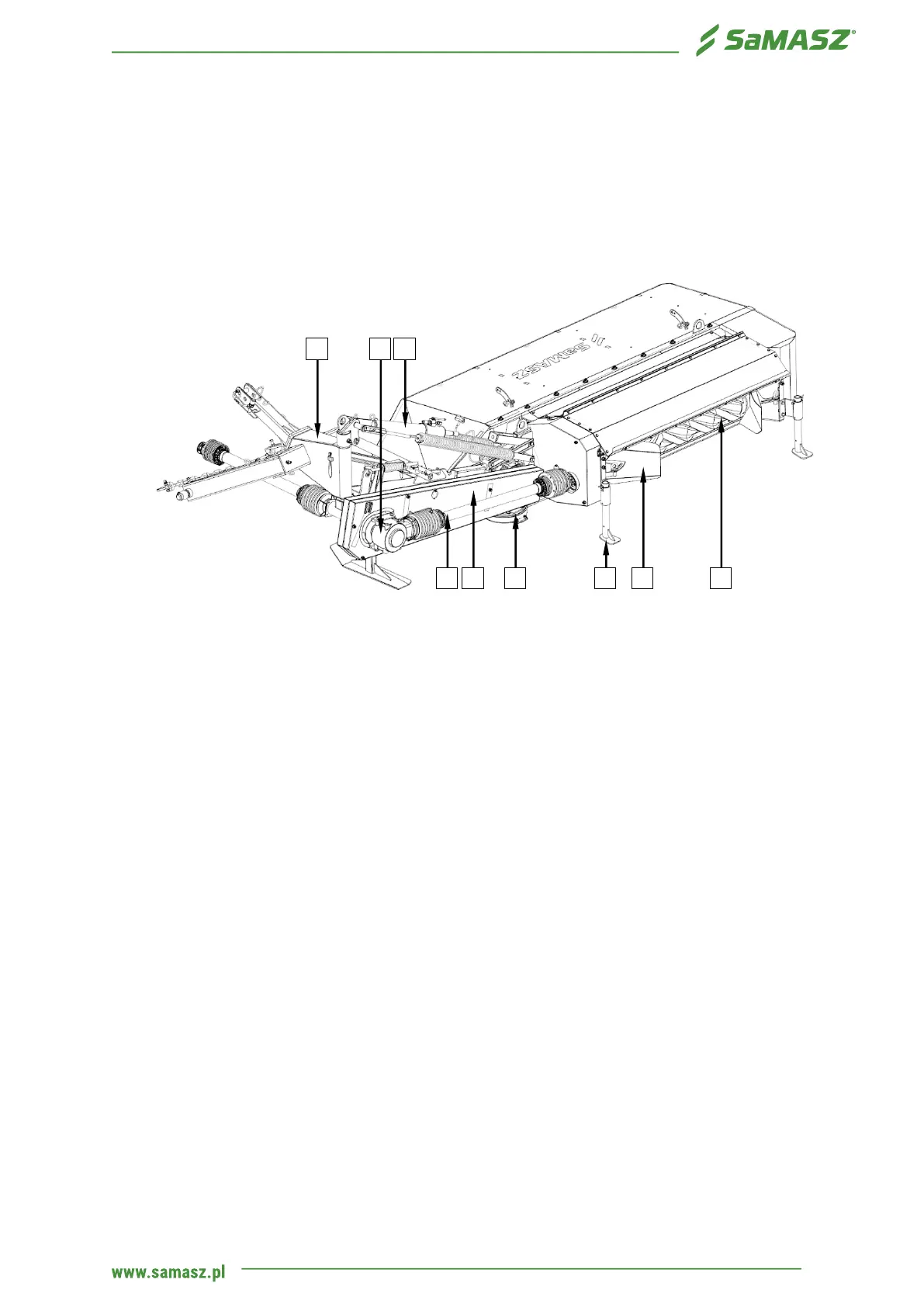

3.2.3. Rear disk mower with roller condioner

Fig. 3c. Parts of SaMASZ rear disc mower with tine conditioner

3-point linkage frame (1) enables attachment of the mower to tractor’s 3-point linkage. Drive from

tractor’s rpm is transmitted through axis gear (3) on the cutterbar (4). On the cutterbar, there are discs

with two knives each. Apart from that, drive from tractor’s rpm through V-belt drive (8) and PTO shaft

(9) is transmitted to roller conditioner (7). Hydraulic cylinder (2) is used to adjust the mower to working

position. It is supplied from outer hydraulics of the tractor. Main frame, on which the cutterbar is

situated, is supported by the springs (2). Swath guides (5) are mounted on the safety guard.

3.3. Standard equipment and spare parts

The mowers are sold with the following standard equipment:

❑ warranty card,

❑ operator's manual with catalogue of spare parts and declaration of conformity,

❑ cutting knives (additional set),

❑ knife mounting key,

❑ PTO shaft,

❑ spray paint (150 ml / 5.3 uk fl oz).

Optional extra equipment:

❑ warning triangle,

❑ topping plates / double topping plates,

❑ cutting disc with instep (set),

❑ double swath guide (only KDT 341),

❑ two swath cutterbar configuration (only KDT 341).

Loading...

Loading...