ADJUSTING SECONDARY SHAFT END FLOAT FOR THE

5-SPEED GEARBOX

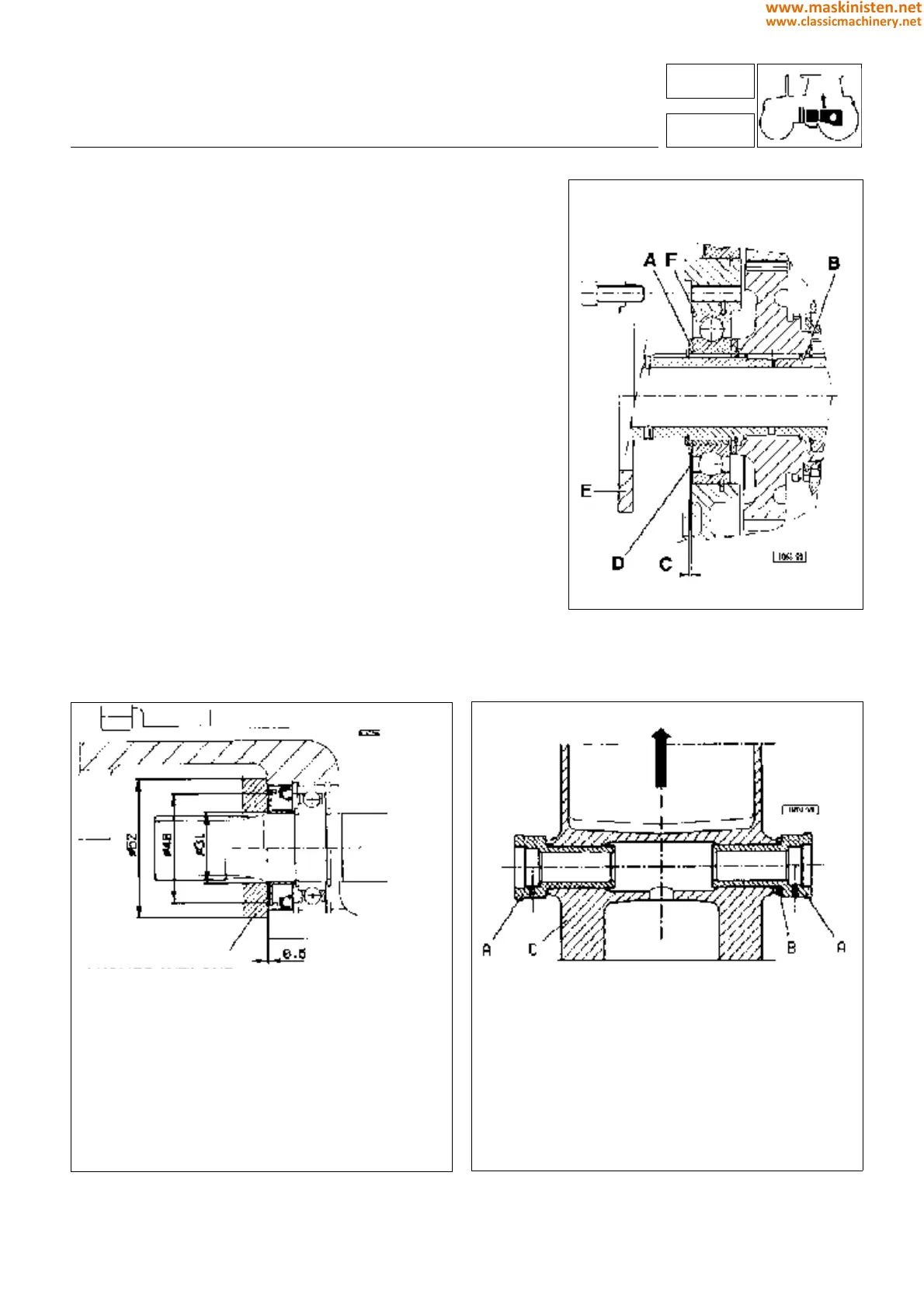

1 - (For all models) - Interpose a calibrated shim A selected from

the following four thickness:

- A code 2.1559.737.0 thickness 2.15 mm;

- A code 2.1559.738.0 thickness 2.30 mm;

- A code 2.1559.739.0 thickness 2.45 mm;

- A code 2.1559.740.0 thickness 2.60 mm;

in order to completely eliminate all end float of the secondary shaft.

2 - (For Agroshift models only) - Proceed as follows:

after having installed bearing F and shaft B, measure the stand-in

C of the face of the bearing relative to the wall of the gearbox

casing whilst pushing the bearing towards the rear of the gearbox

casing. Install shims D to the same thickness as the value mea-

sured, and check, after installation of flange E, that there is no play

or preload on the bearing.

- D code 2.1580.304.0 thickness 0.5 mm;

- D code 2.1580.303.0 thickness 0.2 mm

- D code 2.1580.310.0 thickness 0.05 mm

Fig. 34 - Shimming up the secondary shaft.

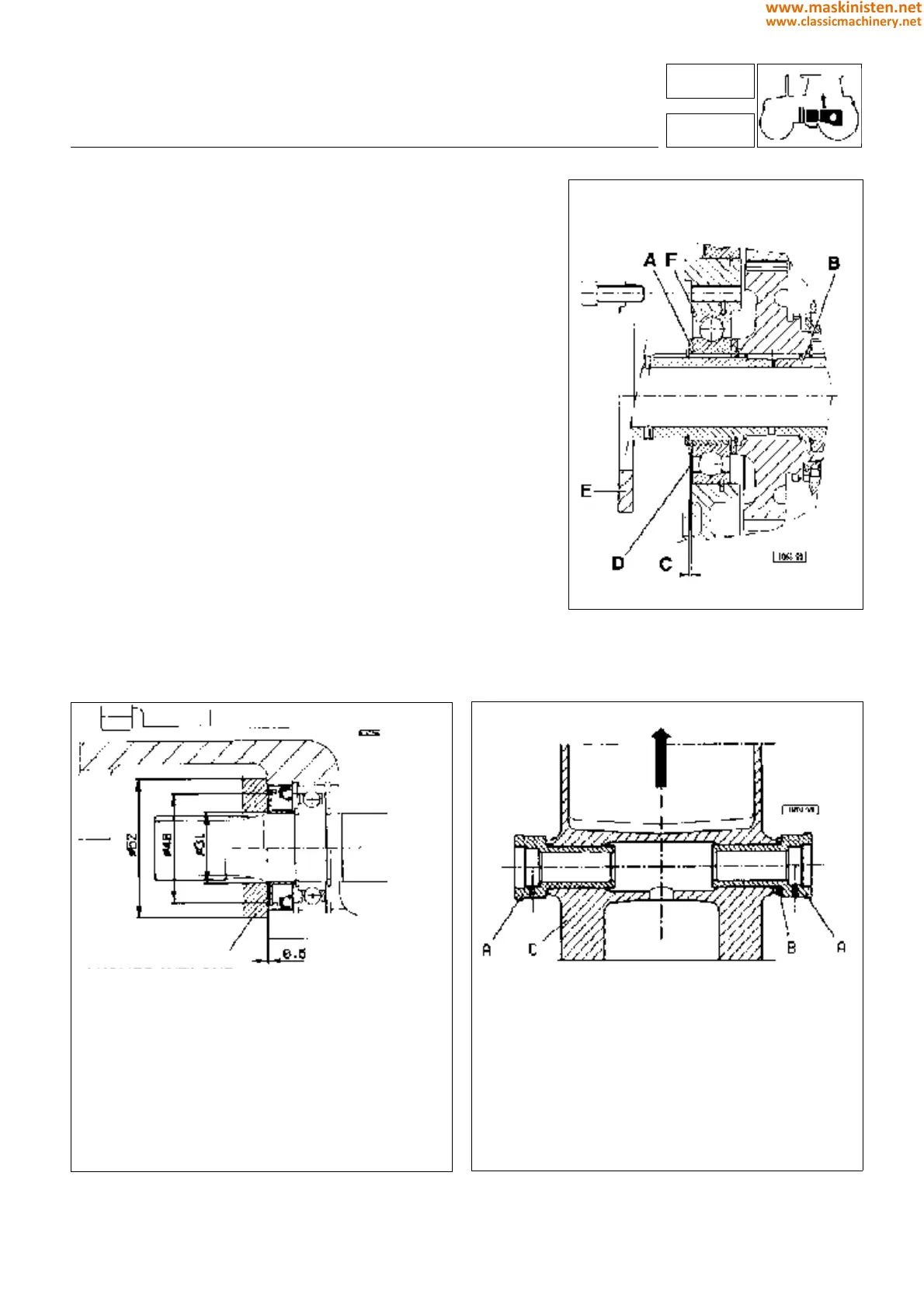

Fitment of spring rod bushes in transmission housing

Chill the two bushes A in liquid nitrogen and press fully

home into the transmission housing C.

The two bushes must be positioned with the threaded

hole directed to the rear as illustrated (the arrow indi-

cates the direction of movement of the tractor).

NB: on 80 - 90 HP machines, position distance rings

B between the bushes and the housing.

Fitment of waterproof seal p/n 2.1529.106.0 to

the 4WD transfer shaft.

The seal is fitted using a special seating tool.

Position the ring as indicated and press in until

recessed 0.1 mm from the face of the transmis-

sion housing.

The dimensions illustrated are for fabrication of

the tool.

Fig. 36 - Fitment of spring rod bushes to transmission housing

(machines equipped with electronic lift system).

Fig. 35 - Fitment of waterproof seal to 4WD transfer shaft.

transmission

primary shaft - secondary shaft - reduction gear unit

3

32-33-34

SEATING TOOL PROFI-

153

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...