Checking the fuel supply pump efficiency (A.C. pump)

This check can be performed by measuring the pump delivery (see on page 19).

If necessary, carry out inner filter cleaning or replcae any items being part of the assembly under overhaul. Full pump

assembly replacement is recommended only if pump casing cracks are noticed.

Bleeding the air from the fuel supply system

The system air-bleeding operation should be made whenever pipe lines are disconnected or there is air in the fuel

supply system.

Operate as follows:

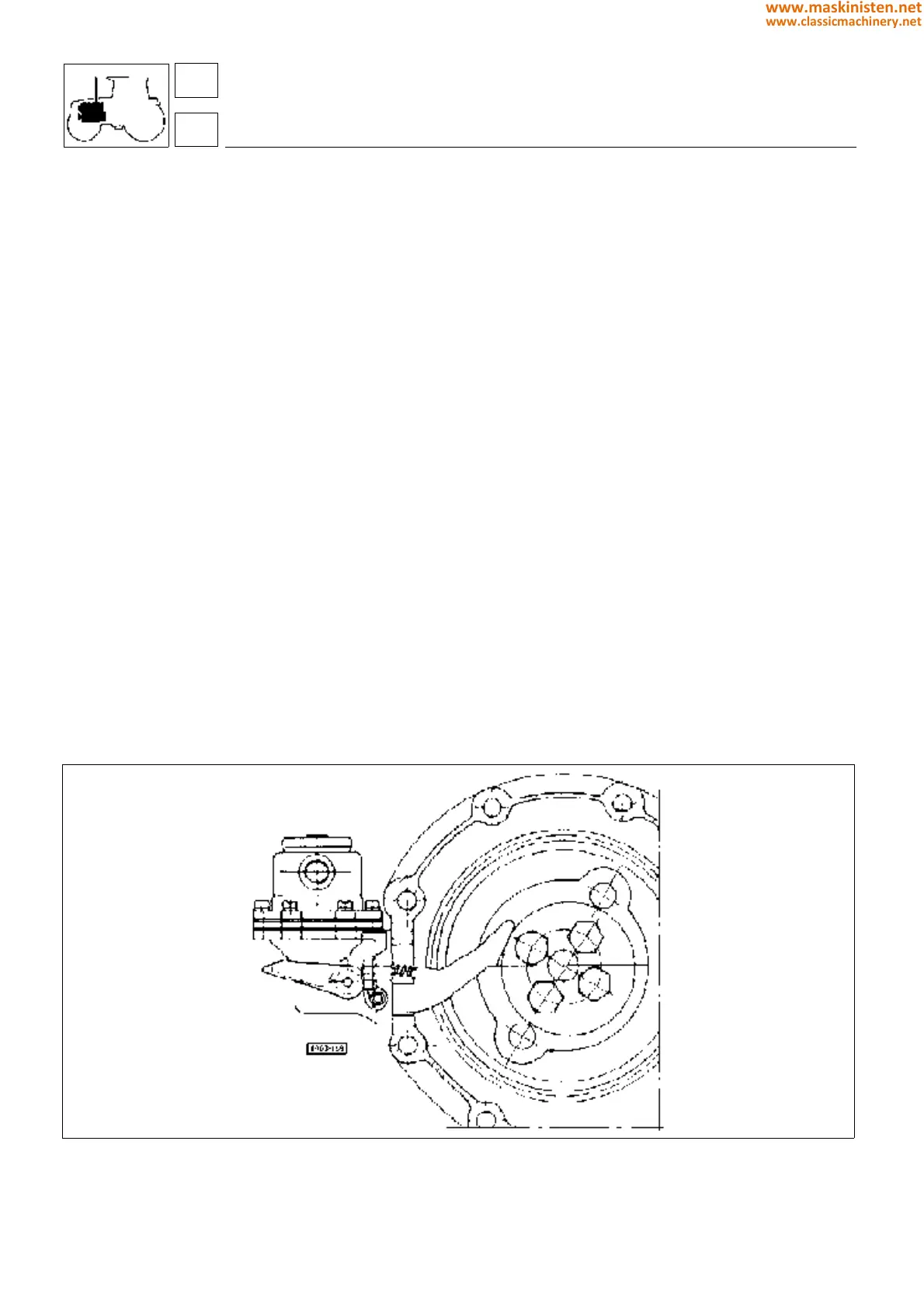

Be sure the fuel tank is filled, then loosen the bleeding valve located in the fuel filter upper side, press on the fuel pump

hand control lever until the fuel flows out without air bubbles. Tighten the retaining screw.

NOTE: While operating the pump control lever, ascertain that a certain resistance is felt. Otherwise set starter going

so as to locate the pump priming position (camshaft control cam at B.D.C.).

Loosen injector pipes only if necessary, set starter going until fuel free of air bubbles flows out of the loosened pipe

fittings. Thereafter tighten fittings to the specified torque.

Fig. 21 - Fuel supply pump control.

engine

fuel system

16

1

82

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...