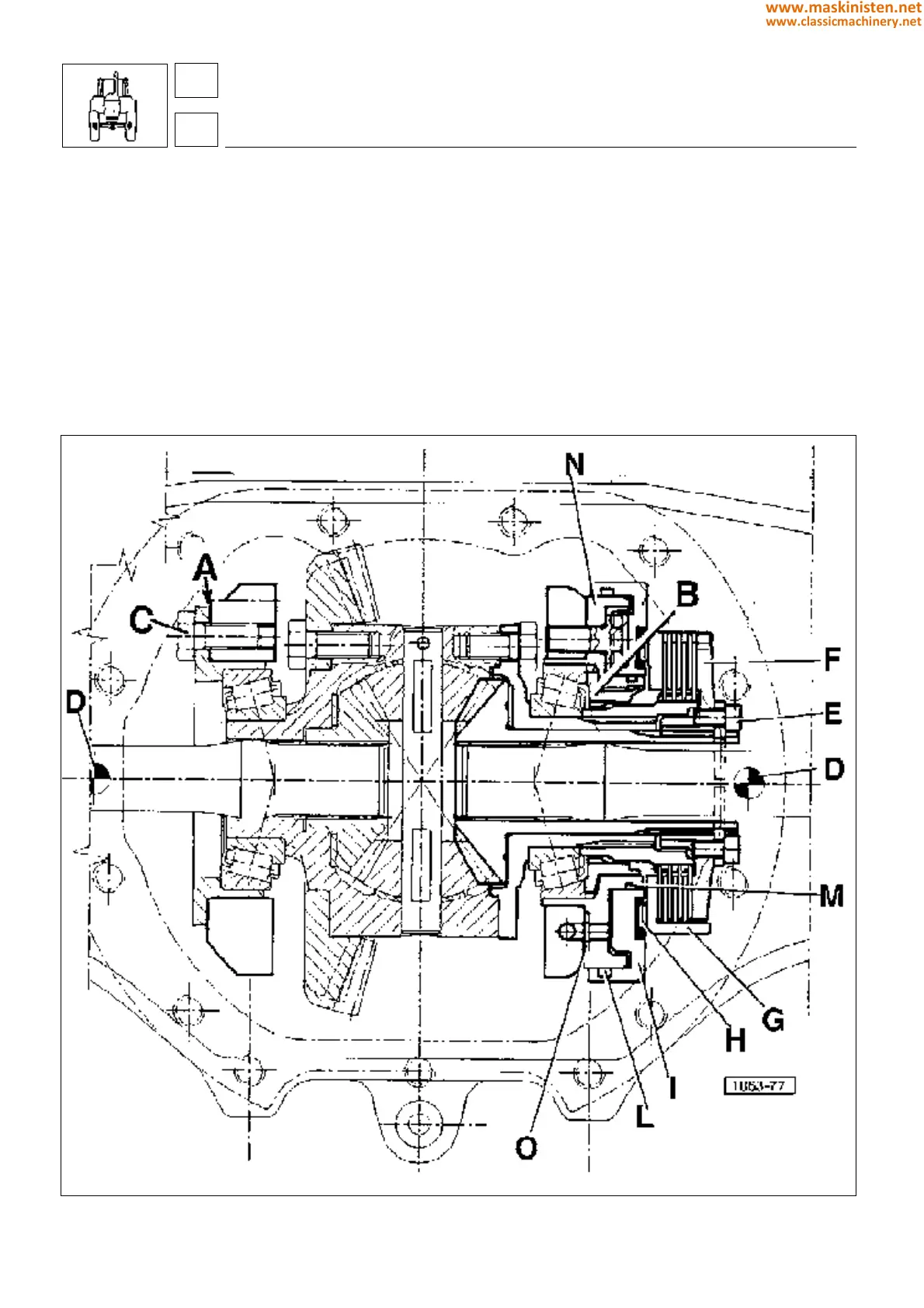

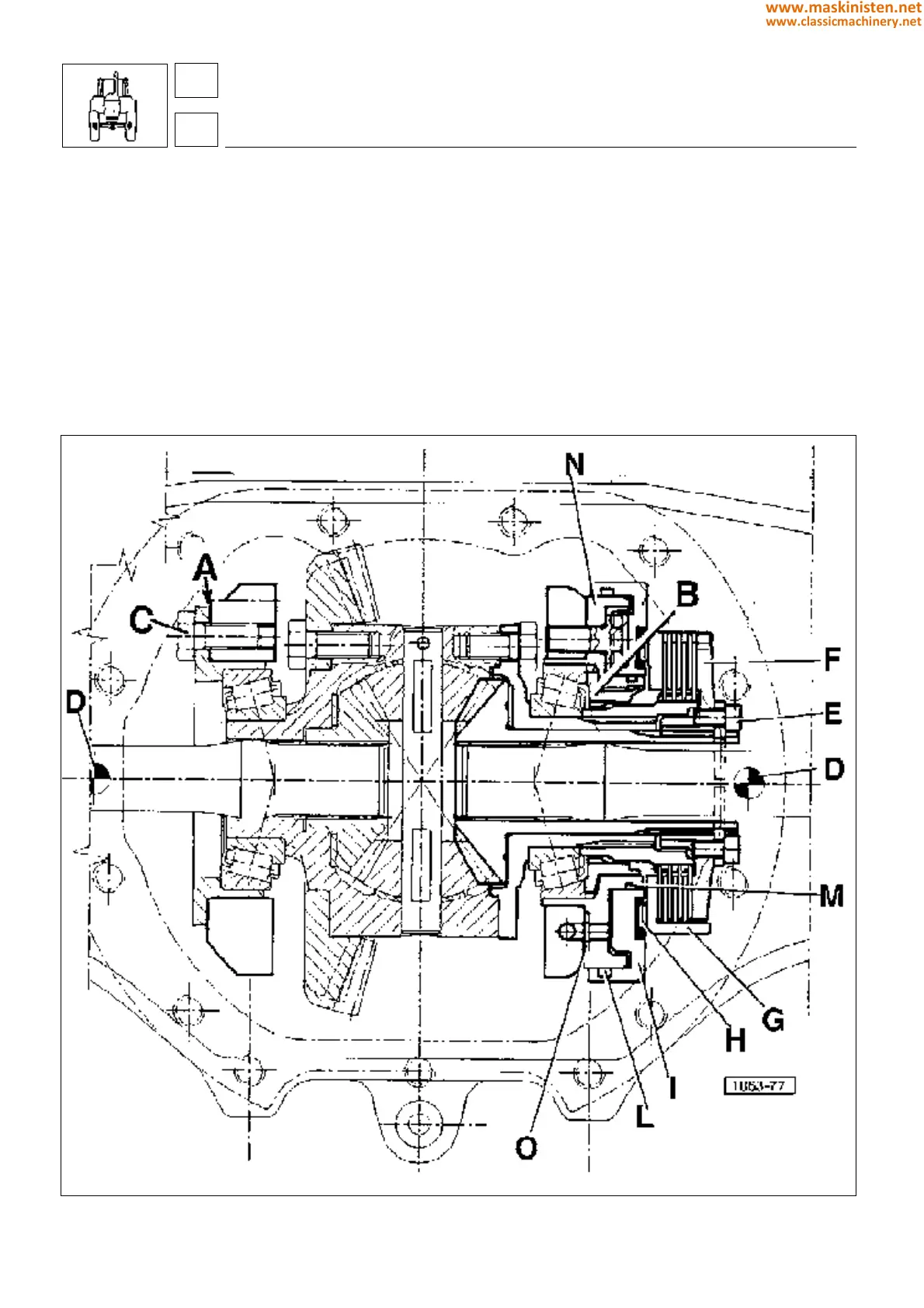

ADJUSTMENT OF FRONT AXLE BEVEL GEAR PAIR ON MACHINES WITH SBA SYSTEM

Having installed the bevel pinion following the directions on page 204, install the crown wheel utilizing the appropriate

number of shims A, p/n 146.4653.0 and 146.4654.0, torque the lock nut B to between 8 and 12 Nm (0.8 - 1.2 kgm),

then verify that backlash between the crown wheel and pinion teeth is between 0.15 and 0.20 mm. If not, adjust by

adding or removing shims at pack A.

Rotate the differential through at least 10 full turns, then retorque the lock nut B to between 2 and 4 Nm (0.2 - 0.4 kgm);

this will ensure that the bearings are neither slack nor preloaded.

Stake the lock nut B at one point only, using a suitable punch.

Remove the bolts C, apply Loctite 242 to the threads, then replace and torque to between 39 and 43 Nm (4 - 4,4 kgm).

Fig. 4 - Section through differential unit on machine with SBA system.

drive axles - axles

4-W.D. front axle

43

4

210

www.maskinisten.net

www.classicmachinery.net

Loading...

Loading...