EB 3136 EN 9

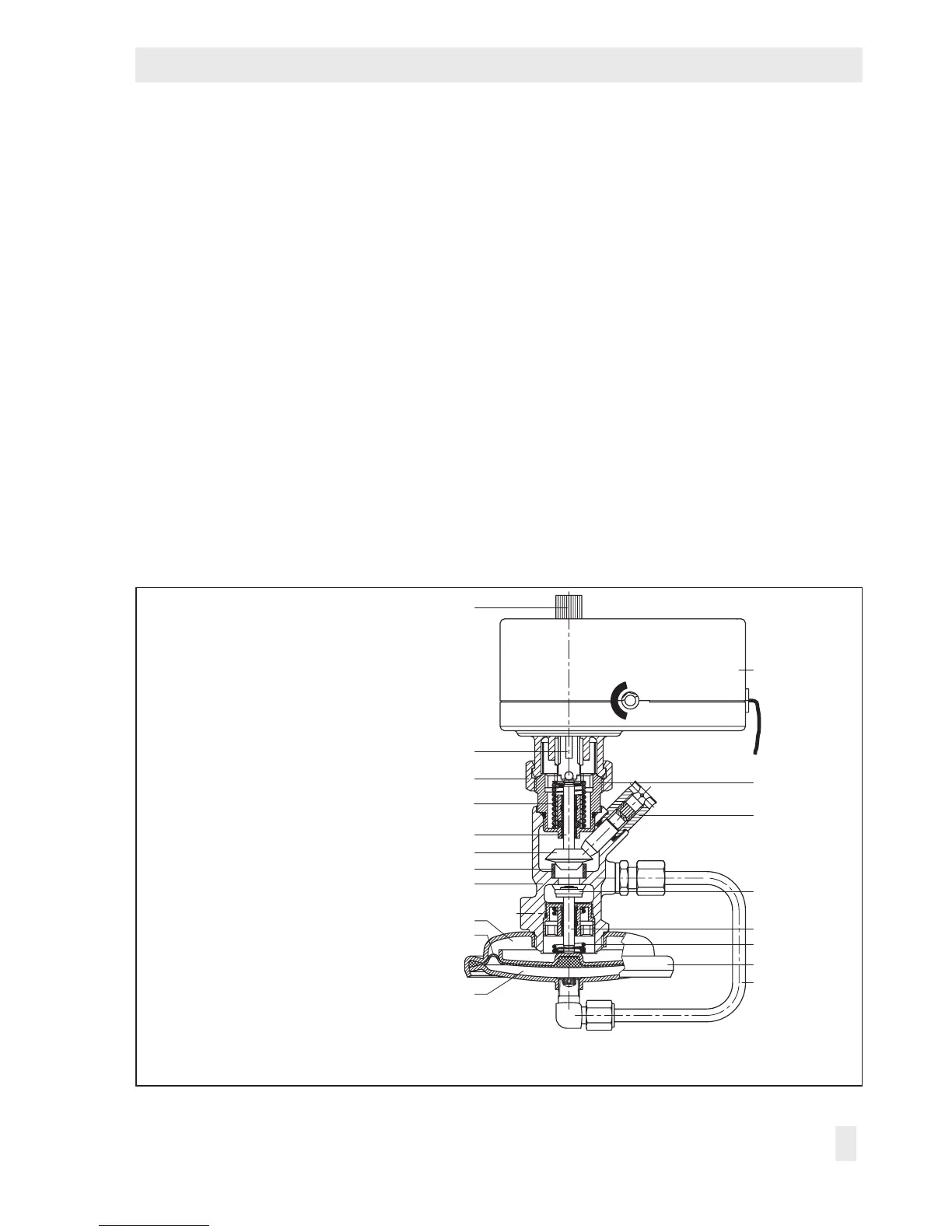

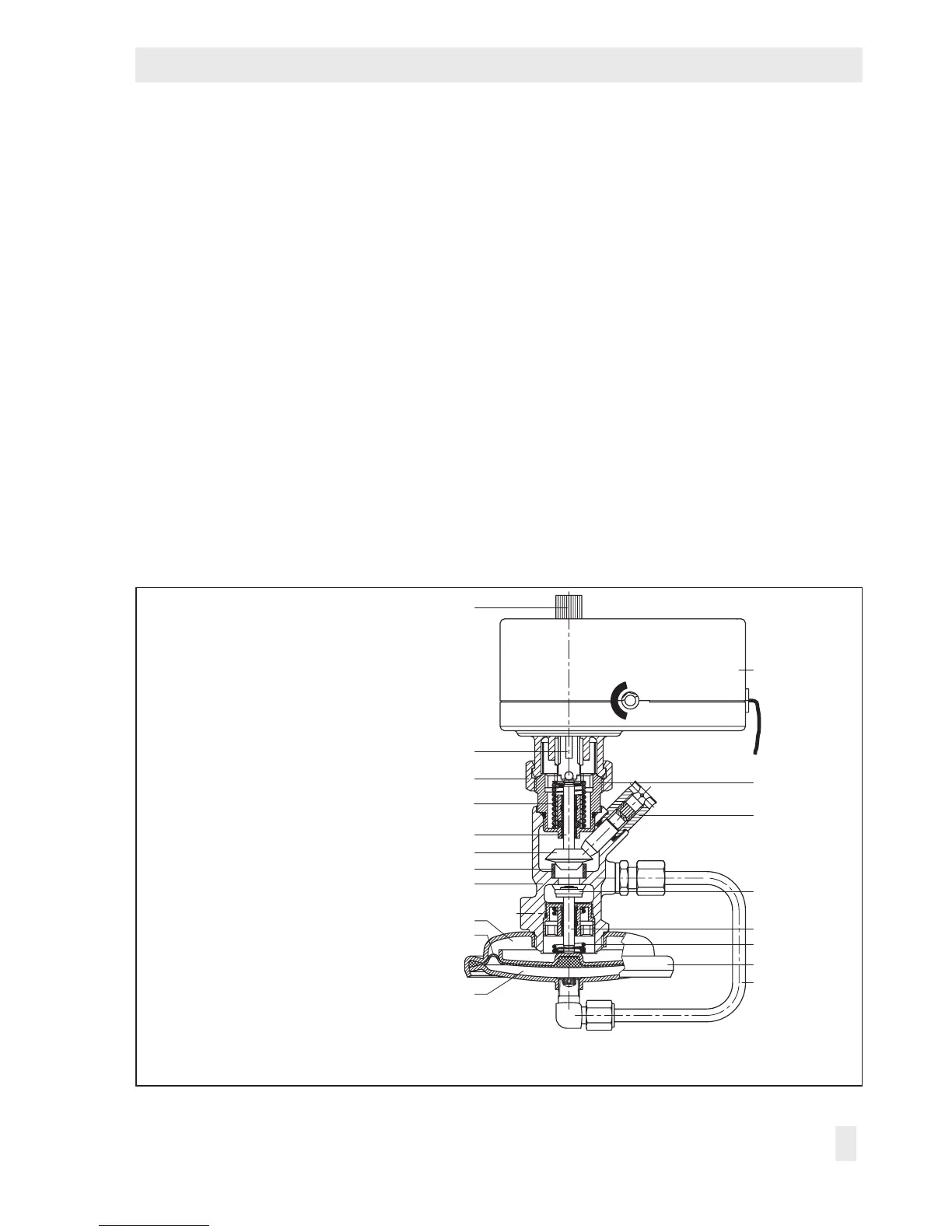

Design and principle of operation

3 Design and principle of oper-

ation

Î Refer to Fig.2

The pressure-independent control valve

(PICV) consists of the Type2488N Flow

Regulator and the Type5857 Electric Actua-

tor. The valve is tted with a connecting

piece for connection of an electric actuator.

As a result, it is possible to transmit the con-

trol signal of an electric control device to

achieve additional temperature control by

changing the restriction position. The medi-

um ows through the valve in the direction

indicated by the arrow on the valve body.

The ow rate is determined by the area re-

leased by the valve plug (3) and the adjust-

able restriction (11).

The installed positioning spring (5) deter-

mines the differential pressure across the re-

striction of 0.2bar. The pressure upstream of

the restriction (11) is transmitted over the

control line (7) to the upstream pressure side

of the actuator. The pressure downstream of

the restriction acts on the low-pressure side

of the operating diaphragm (9) through a

hole in the valve plug. The differential pres-

sure generated at the restriction is converted

into a positioning force by the operating dia-

phragm. This force is used to move the valve

plug depending on the force of the position-

ing spring (5). The ow rate is adjusted at

the set point screw (13).

1 Valve body

2 Seat

3 Plug

4 Plug stem

5 Positioning spring

6 Diaphragm actuator

7 Control line for upstream pressure

8 Upstream side

9 Operating diaphragm

10 Downstream side

11 Restriction

12 Restriction stem

13 Set point screw for ow control

14 Connecting piece

15 Spring

16 Type5857 Electric Actuator

17 Coupling nut

(max. 20Nm tightening torque)

18 Actuator stem

19 Manual adjuster

1

11

Loading...

Loading...