8-2 EB 8222-1 EN

Malfunctions

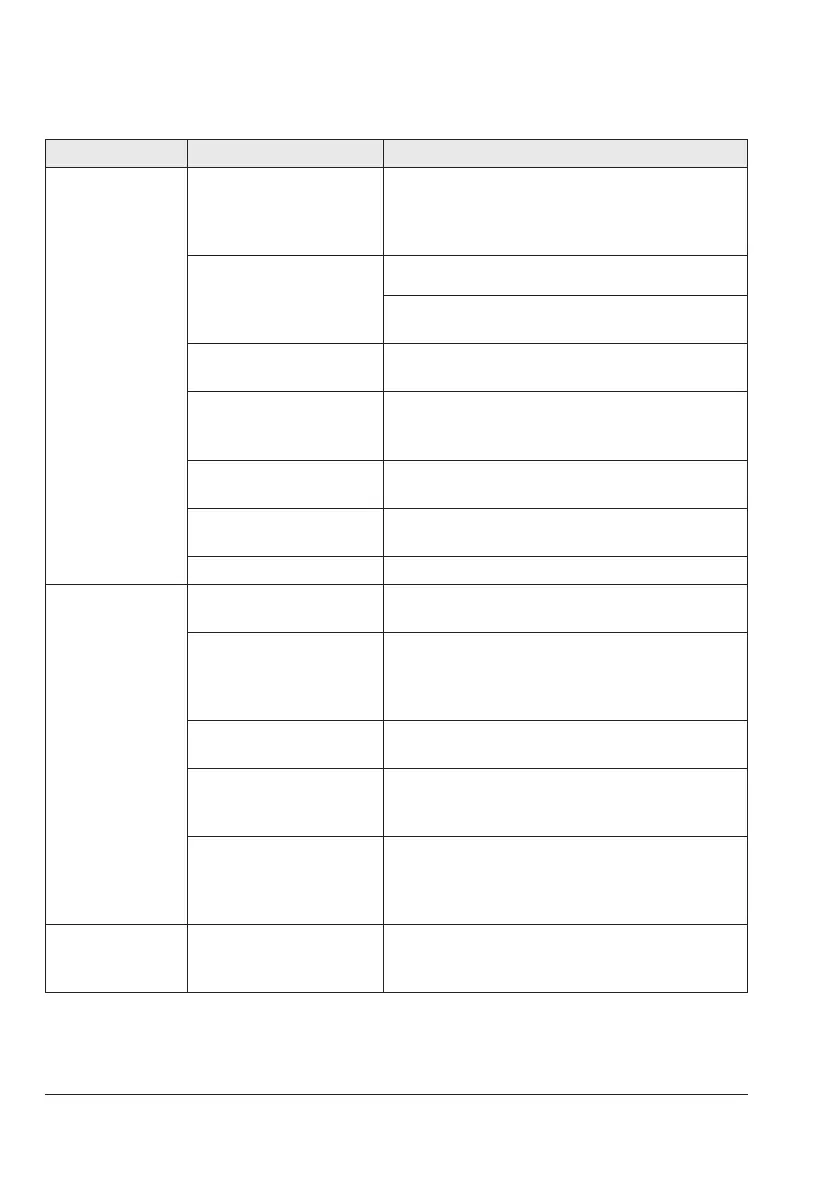

Malfunction Possible reasons Recommended action

Increased ow

through closed

valve (seat leak-

age). The leakage

class specication

cannot be met.

Dirt or other foreign parti-

cle deposits have collected

inside the valve.

Shut off the section of the pipeline and ush the

valve.

Depressurize valve and actuator. Use a cloth to

clean the segmented ball and seat ring.

Clearance (play) in the

connection between the ac-

tuator and valve shaft/

shaft adapter.

Shaft end with square drive: insert thin wedges.

Shaft end with key drive: replace feather key.

Incorrect setting of stop

bolts

Readjust stop bolts (see the 'Installation' section >

'Mounting the actuator onto the valve').

Markings on the actuator

shaft and packing gland

not aligned with each other

Align the markings. They indicate the best closed

position of the valve.

Segmented ball not correct-

ly centered

Contact our after-sales service.

Seat ring worn out Replace seat ring (see 'Service and conversion work'

section > 'Replacing the seat ring').

Segmented ball worn out Contact our after-sales service.

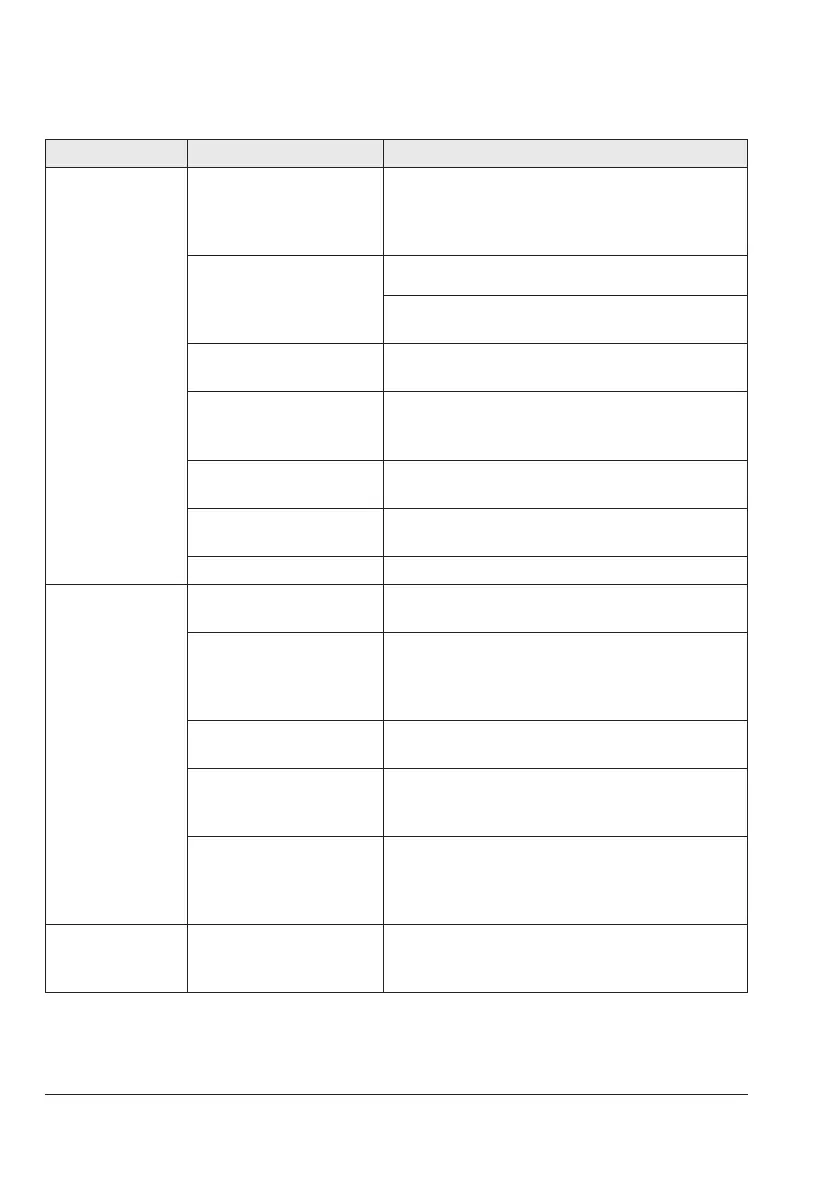

The valve leaks to

the atmosphere (fu-

gitive emissions).

Defective packing Replace packing (see 'Service and conversion work'

section > 'Replacing the packing').

Flange joint loose or gasket

defective

Check the ange joint.

Put the control valve out of operation (see the 'De-

commissioning' section) and renew the gasket at the

anged joint.

Gasket on the retainer de-

fective

Replace gasket (see 'Service and conversion work'

section > 'Replacing the seat ring').

Gasket on the bottom

ange defective

Put the control valve out of operation (see the 'De-

commissioning' section) and renew the gasket be-

tween the bottom ange and valve body.

Version with insulating sec-

tion: gasket between valve

body and insulating section

defective

Put the control valve out of operation (see the 'De-

commissioning' section) and renew the gasket be-

tween the valve body and insulating section.

Flow rates do not

meet the specica-

tions

Wrong characteristic See 'Service and conversion work' section >

'Changing the characteristic'.

Loading...

Loading...