S&C Instruction Sheet 761-545 13

Installation

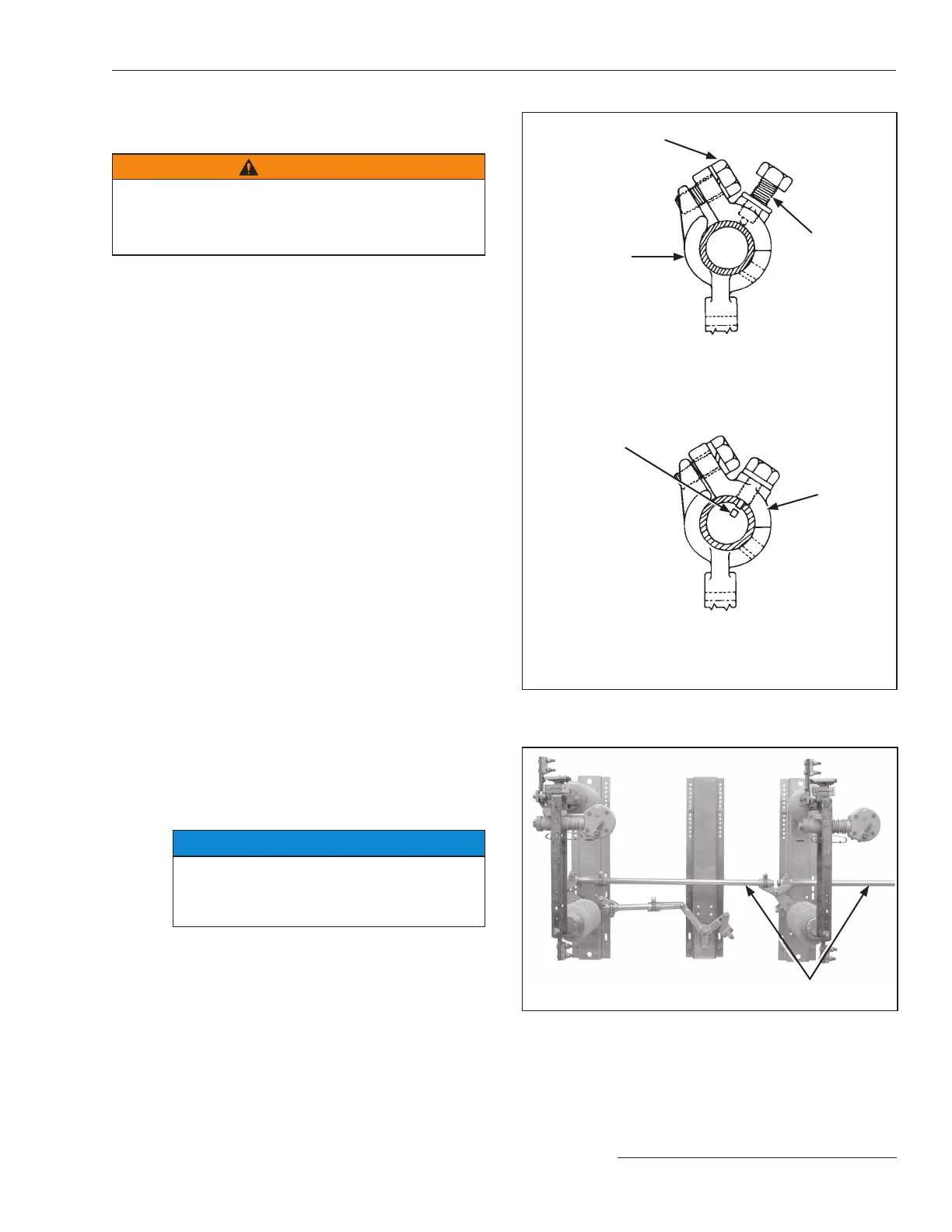

Installing Pipe Couplings with Piercing Set

Screws

WARNING

Failure to properly install pipe couplings with piercing

set screws can cause slippage of operating pipe,

resulting in improper operation of the switch, arcing,

equipment damage, or electrical shock.

STEP 9. To properly install piercing set screws:

(a) Make sure the cutting tip of the piercing set

screw does not protrude through the body of

the clamp.

(b) Insert the operating pipe section into the

coupling and nger-tighten the clamp bolt(s).

(c) Adjust the operating pipe to the correct

length. Then, tighten the clamp bolt(s) to

nal tightness.

(d) Tighten the piercing set screw, piercing the

pipe, and continue turning until a rm

resistance is felt.

(e) Make sure the clamp bolt(s) are tight. See

Figure 11.

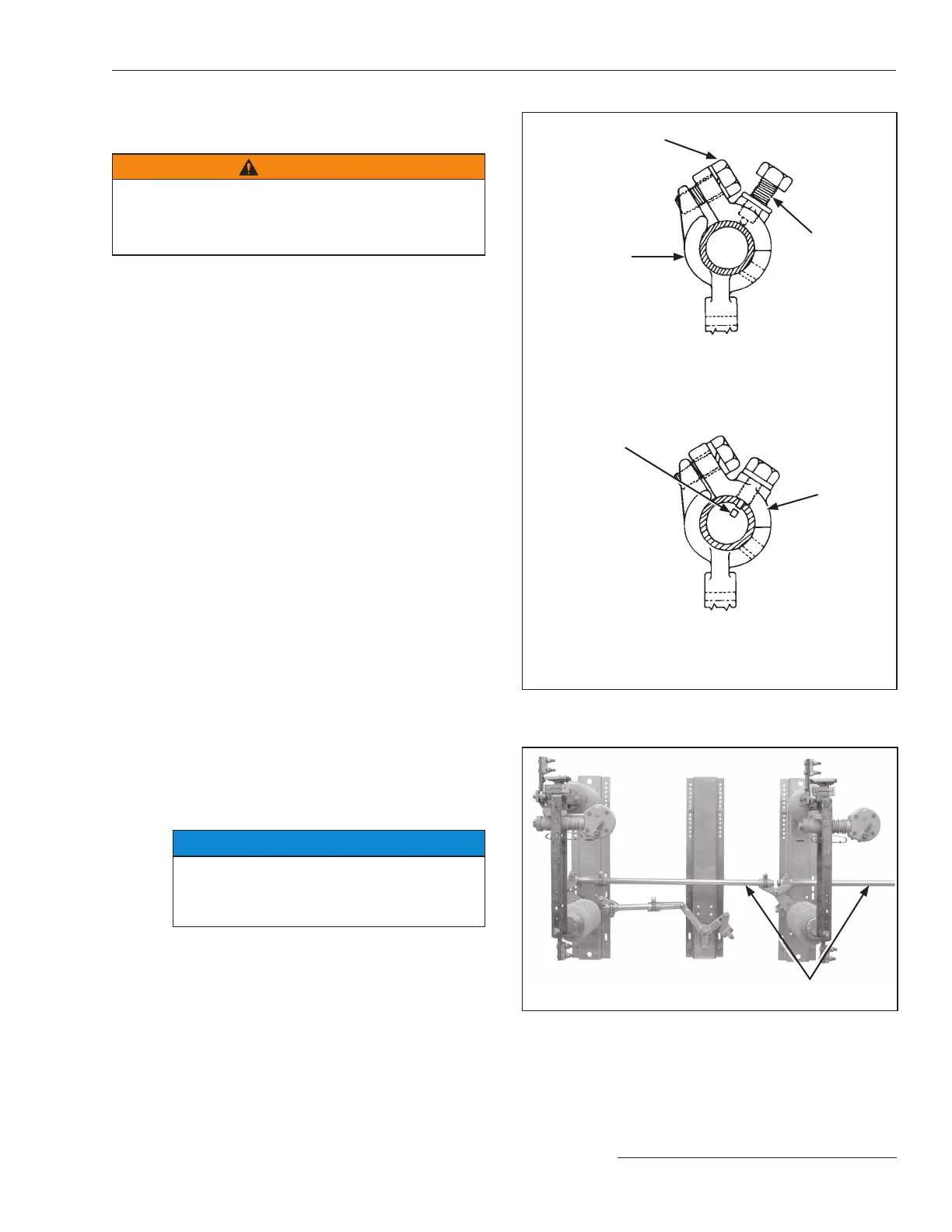

Installing the Interphase Pipe

STEP 10. Install the horizontal pipe sections connecting

the switch poles and the bell-crank assembly.

See Figure 12. Follow the directions in the

“Installing Pipe Couplings with Piercing Set

Screws” section.

Torque the clamp bolt of each pipe-coupling

clamp to final tightness, but do not tighten the

associated set screw until the mechanism has

been adjusted to attain full closure of all three

poles.

STEP 11. Make sure the bell-crank is held in the 45-degree

position. The bell-crank and bell-crank bearing

have indexing ridges to facilitate this alignment.

See Figure 10 on page 12.

NOTICE

The bell-crank arms should be within 5 degrees

of the 45-degree position for the most favorable

mechanical advantage when the switch is in

both the Open and Closed positions.

Figure 12. Pipe connecting the switch poles.

Interphase pipe sections

Figure 11. Installing the pipe couplings.

Piercing set screw in the shipping position (cutting

tip does not pro trude through the body of the clamp)

Operating pipe installed, clamp bolt fully tightened, and

piercing set screw in final position

Clamp bolt

Clamp

Coupling body

Piercing

set screw

Slug pierced

from pipe

Loading...

Loading...