DISASSEMBLE OF THE CD MECHANISM

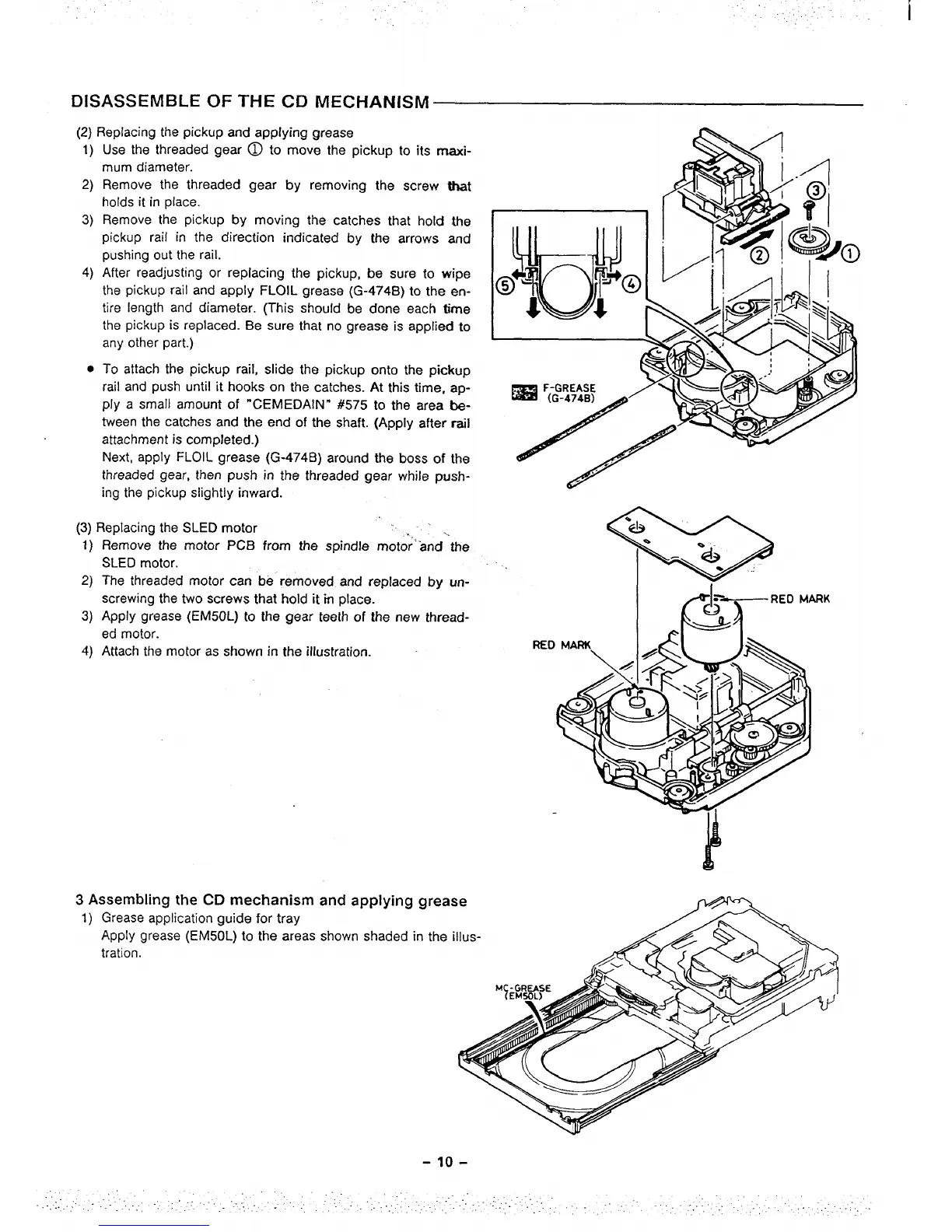

(2) Replacing the pickup and applying grease

1)

2)

3)

4)

●

Use the threaded gear @ to move the pickup to its maxi-

mum diameter.

Remove the threaded gear by removing the screw that

holds it in place.

Remove the pickup by moving the catches that hold the

pickup rail in the direction indicated by the arrows and

pushing out the rail.

After readjusting or replacing the pickup, be sure to wipe

the pickup rail and apply FLOIL grease (G-474B) to the en-

tire length and diameter. (This should be done each time

the pickup is replaced. Be sure that no grease is applied to

any other part.)

To attach the pickup rail, slide the pickup onto the pickup

rail and push until it hooks on the catches. At this time, ap-

ply a small amount of “CEMEDAIN” #575 to the area be-

tween the catches and the end of the shaft. (Apply after rail

attachment is completed.)

Next, apply FLOIL grease (G-474B) around the boss of the

threaded gear, then push in the threaded gear while push-

ing the pickup slightly inward.

(3) Replacing the SLED motor

..

! ..

1)

2)

3)

4)

Remove the motor PCB from the spindle motor’ and the

SLED motor.

The threaded motor can be removed and replaced by un-

screwing the two screws that hold it m place.

Apply grease (EM50L) to the gear teeth of the new thread-

ed motor.

Attach the motor as shown in the illustration.

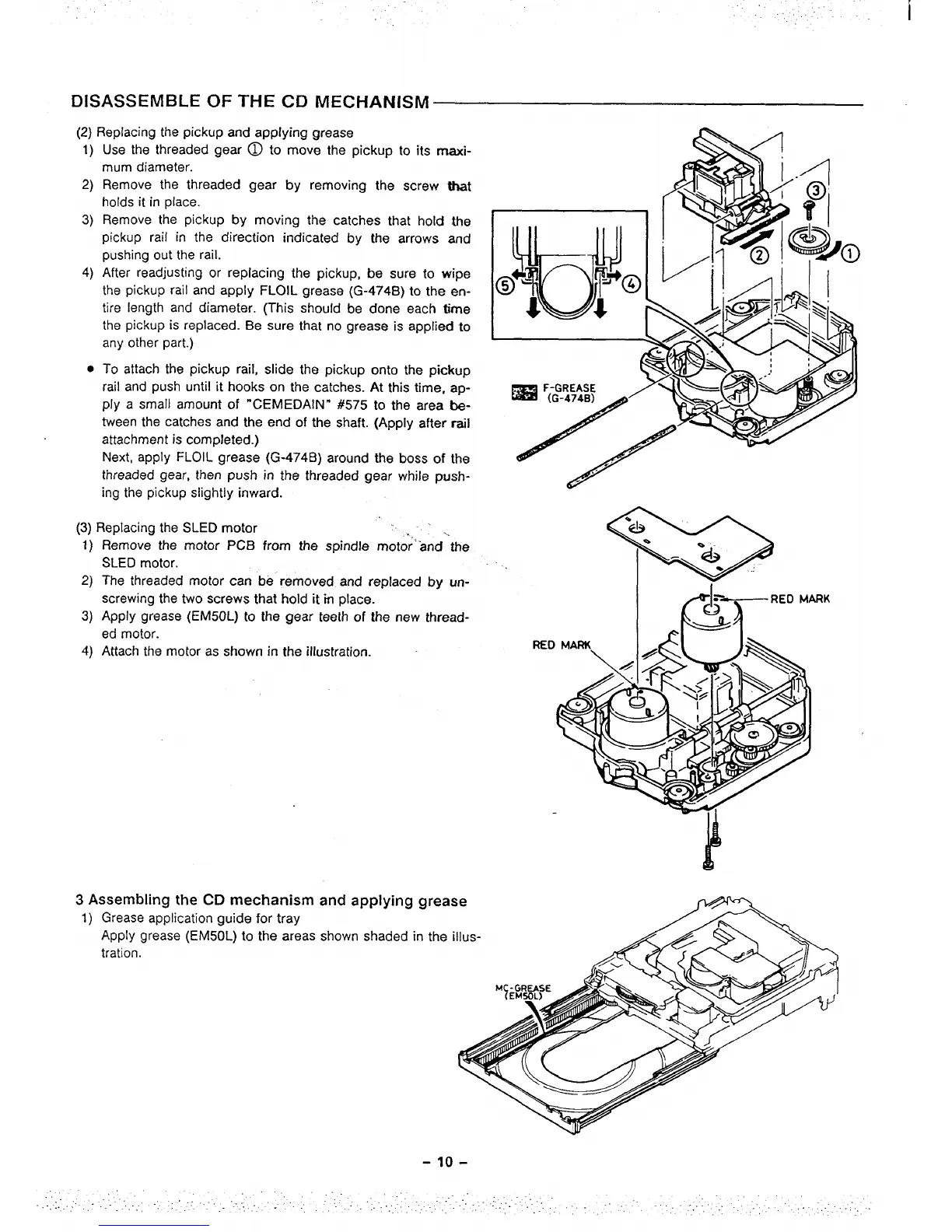

3 Assembling the CD mechanism and applying grease

1) Grease application guide for tray

Apply grease (EM50L) to the areas shown shaded in the illus-

tration.

.-...... . .

@

i!!

-1o-

Loading...

Loading...