16

Section 4

4.2 CONTROLS IDENTIFICATION

1. Ignition Switch (Figure 4-2). The ignition switch

is used to start the engine and has three positions;

OFF, ON, and START.

2. Engine Choke Control (Figure 4-2). Used to start a

cold engine.

3. Engine Throttle Control (Figure 4-2). Used to

control the engine speed. Pushing the lever forward

increases engine speed. Pulling the lever back

decreases engine speed. Full back position is the

IDLE position. Full forward is the driving position.

4. Left Steering Control (Figure 4-2). Used to control

the machine's left wheel when traveling forward or

reverse. See Section 4.7 for further details regarding

the machine's travel controls.

5. Right Steering Control (Figure 4-2). Used to

control the machine's right wheel when traveling

forward or reverse. See Section 4.7 for further details

regarding the machine's travel controls.

6. Parking Brake Control (Figure 4-2). Used to

engage and disengage the parking brakes and lock

the steering handles in neutral. Pull the lever back to

engage the parking brakes. Push the lever forward

to disengage the parking brakes.

7. Fuel Tank Gauge (Figure 4-2). Indicates the amount

of fuel in the fuel tank.

8. Fuse Holders (Figure 4-2). Three (3) 20-amp fuses

protect the machine’s electrical system. To replace

fuses, pull fuse out of the socket and install a new

fuse.

9. Fuel Shutoff Valve (Figure 4-2). Located on top

of the fuel tank. Used to shut off fuel supply to the

engine. Rotate the valve counter clockwise to supply

fuel from the tank to the engine. Rotate the valve

clockwise to shut off the fuel supply to the engine.

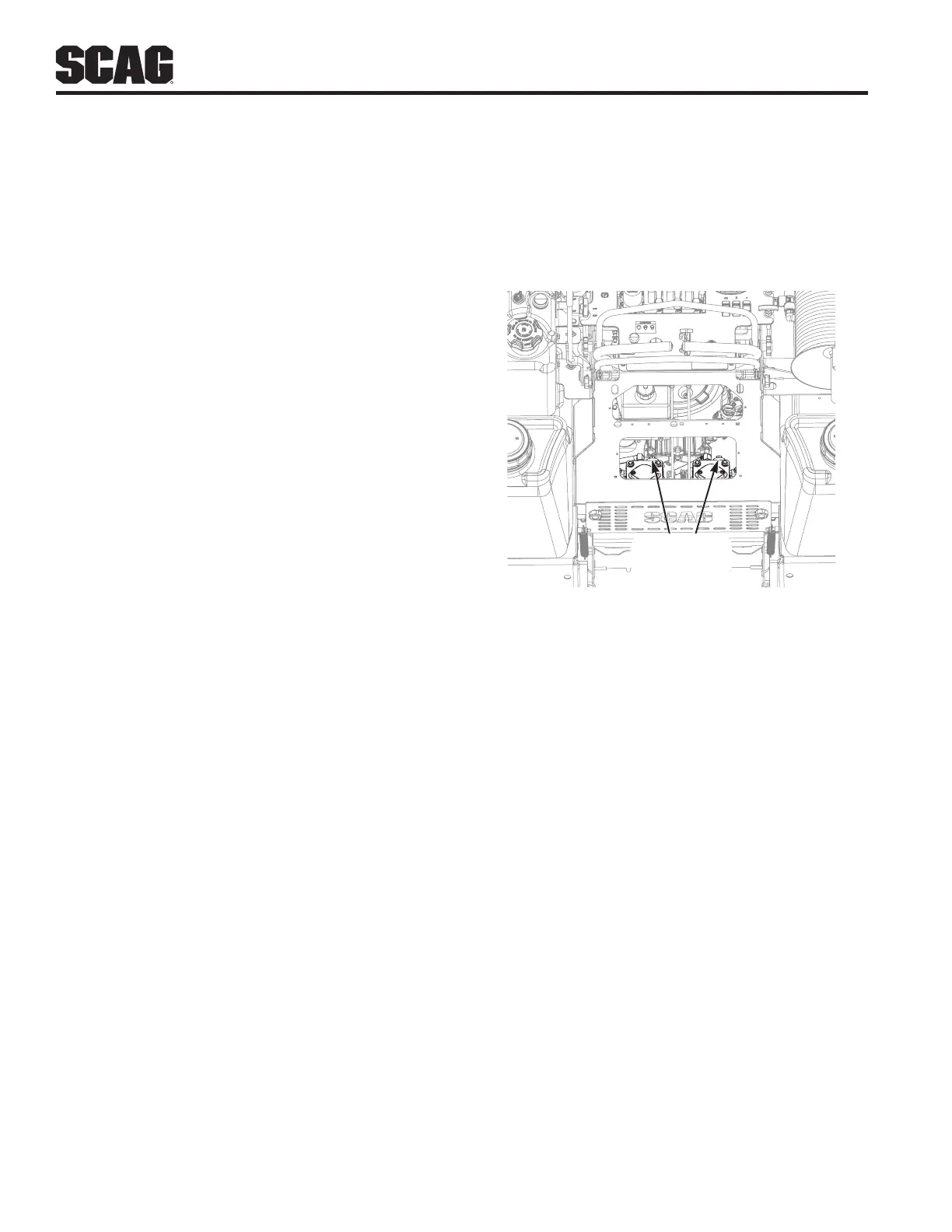

10. Dump Valve Controls (Figure 4-3). Located on the

hydraulic pumps, used to “free-wheel” the machine.

Rotating clockwise until they stop, allows the unit

to move under hydraulic power. The levers must

be in this position and torqued to 7-10 lb-ft during

operation of the machine. Rotating counter-clockwise

allows the machine to be moved by hand (free-

wheeling). See Figure 4-3.

11. Hourmeter (Figure 4-1). Indicates the number of

hours the engine has been operated. It operates

whenever the engine is running. Has preset

maintenance reminders for engine and hydraulic

system oil changes. Will start flashing scheduled

maintenance 2 hours before preset time and

continue flashing until 2 hours after. Automatically

resets.

DUMP VALVE

LOCATION

Figure 4-3. Dump Valve Controls

12. Pressure Control Valve (Figure 4-2). Located in the

control panel cut out, the sprayer pressure adjuster

is used to adjust the spray system pressure.

13. Pressure Guage (Figure 4-2). Located in the

control panel cut out, is used to display the sprayer

systems pressure. When the spray nozzles are open,

the sprayer system pressure will decrease slightly.

Adjust the Pressure Control Valve to compensate for

the loss in pressure.

14. Left Boom Sprayer Nozzle Selector (Figure 4-2).

Located in the control panel cut out, allows the

operator to turn the left hand spray boom nozzle on

or off.

15. Center Boom Sprayer Nozzle Selector (Figure

4-2). Located in the control panel cut out, allows the

operator to turn the center spray boom nozzles on or

off.

16. Right Boom Sprayer Nozzle Selector (Figure

4-2). Located in the control panel cut out, allows the

operator to turn the right hand spray boom nozzle on

or off.

17. Strainer (Figure 4-2). Located next to the pump, the

strainer filters the sprayer system and traps debris

inside of the system before reaching the sprayer

pump.

Loading...

Loading...