42

Section 6

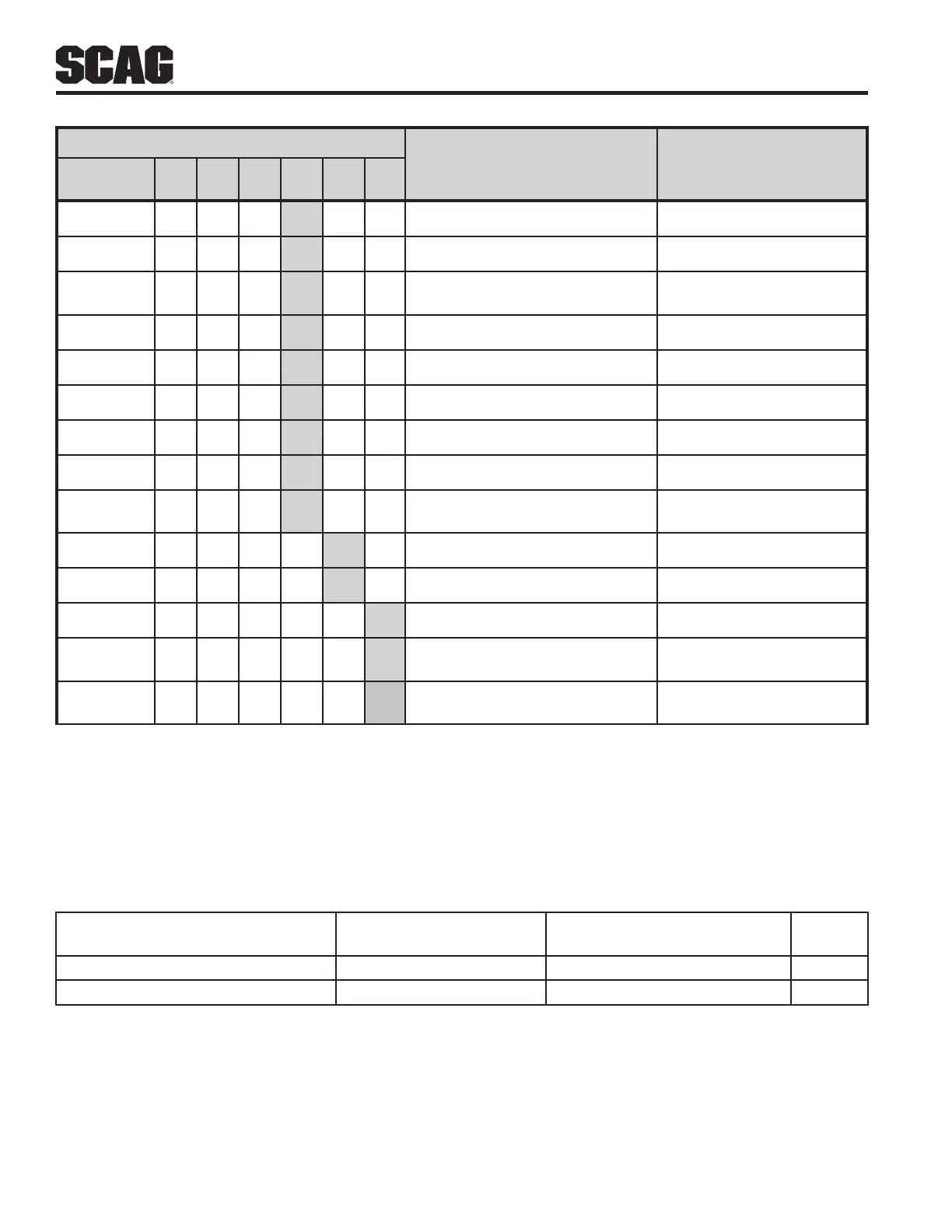

HOURS

PROCEDURE COMMENTS

BREAK-IN

(FIRST 10)

8 20 40 100 200 500

X

Check belt for proper alignment See paragraph 6.5

X

Check condition of fuel lines

X

Drain hydraulic system and replace

oil and filter

See paragraph 6.3

X

*Clean engine air filter See engine operator's manual

X

Apply grease to fittings See paragraph 6.2

X

Check all hardware for tightness

X

Change engine oil See paragraph 6.4

X

*Clean air cleaner element See paragraph 6.6

X

Initial hydraulic system drain and

replace oil and filter

See paragraph 6.3

X Check hydraulic oil level See paragraph 6.3

X Change engine oil filter See paragraph 6.4

X Replace engine fuel filter See paragraph 6.5

X Drain hydraulic system and replace

oil and filter

See paragraph 6.3

X Replace spray system pump

diaphram

See Pump Manufacturer

* Perform these maintenance procedures more frequently under extreme dusty or dirty conditions, as well as when using

aggressive chemicals.

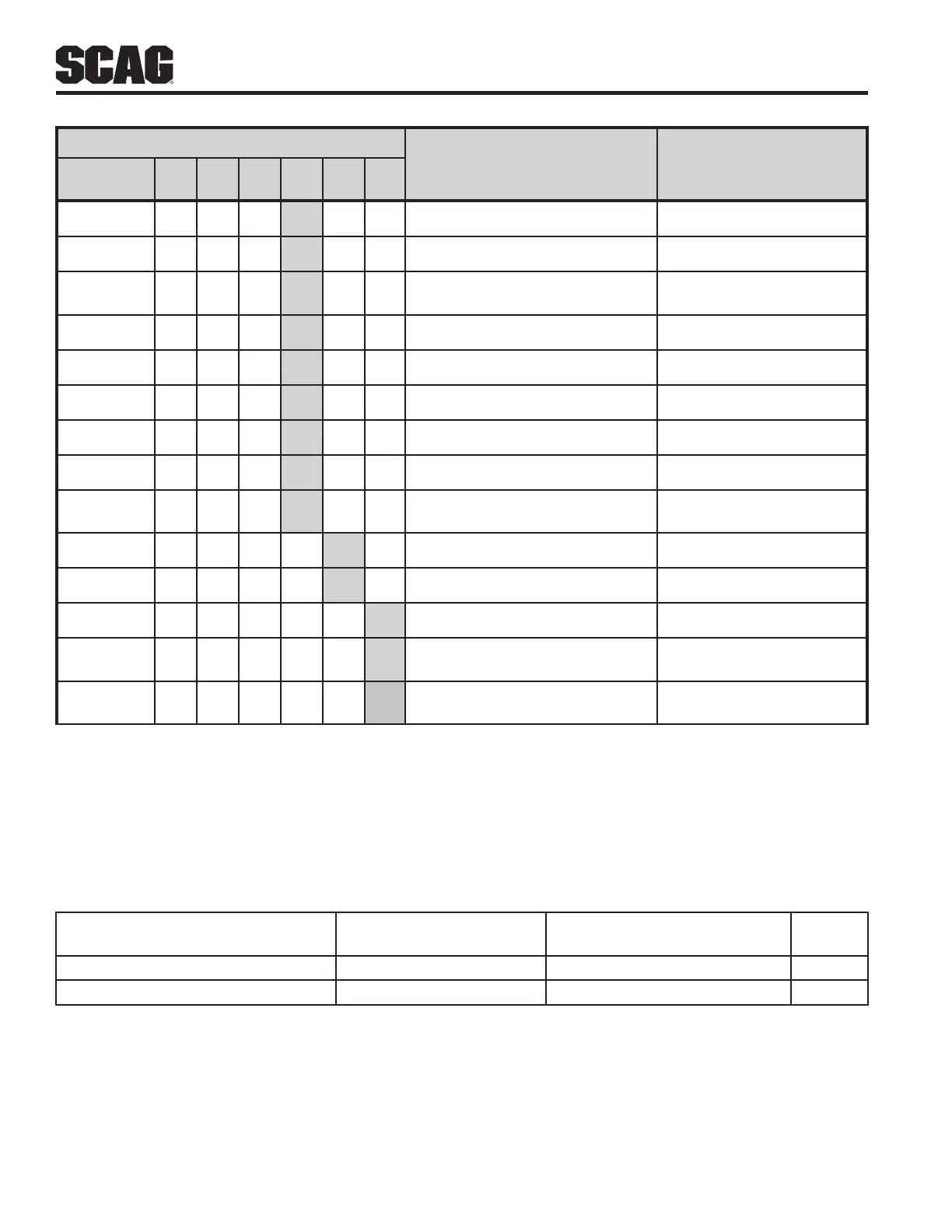

6.2 LUBRICATION

GREASE FITTING LUBRICATION CHART

LOCATION LUBRICATION INTERVAL LUBRICANT

NO. OF

PLACES

1 - Caster Wheel Pivot 500 Hours / Yearly Chassis Grease 2

2 - Caster Wheel Bearings 100 Hours / Monthly Chassis Grease 2

+ Compatible Greases: Scag Premium Chassis Grease p/n 486257

Figure 6-1. Lubrication Fitting Points

Loading...

Loading...