34

Section 5

4. Establish a test area (make sure this area is an area

that you wouldn't mind having streaking or burning from

the fertilizer, OR use a paved surface and collect all of

the material after, to avoid possibility of turf damage

from run off).

5. Adjust the granular drop rate cam to the desired

application rate. Refer to the Spreader Chart in Section

5-10 (this is a starting point).

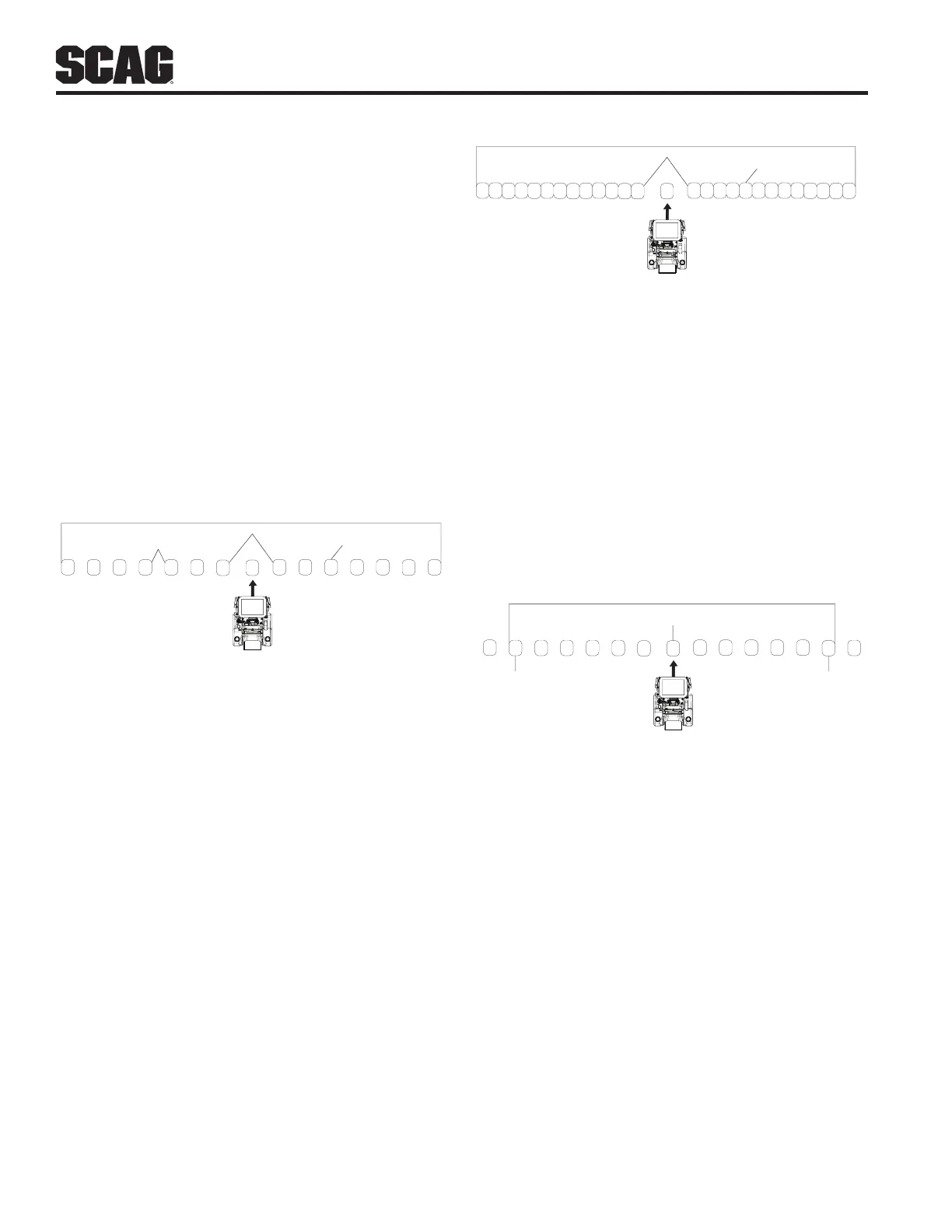

6. To determine the effective spread width for large

granular items you will need 15 small pans (1ft², 1 or

2 inches high). Arrange 7 pans to the right (about 1

foot apart), 7 pans to the left (about 1 foot apart), and

1 pan in the center. Make sure to allow room for the

machine to drive between the 7 left pans and 7 right

pans with the center pan placed so it will miss the drive

tires and go underneath the machine during the pass.

See Figure 5-9

CL1 R1 R2 R3 R5R4 R6 R7L2L3L4L5L6L7

1 Foot Gap

Machine Width (+2 Inches on each side)

Pan (1’x1’x2”)

About 29 Feet

Figure 5-9. Large Granular Material

- NOTE -

Give the machine plenty of room to make the pass.

Operate the machine at "application" speed while

making the pass. Activate the spreader with ample

time to create a consistant path before getting to

the pans.

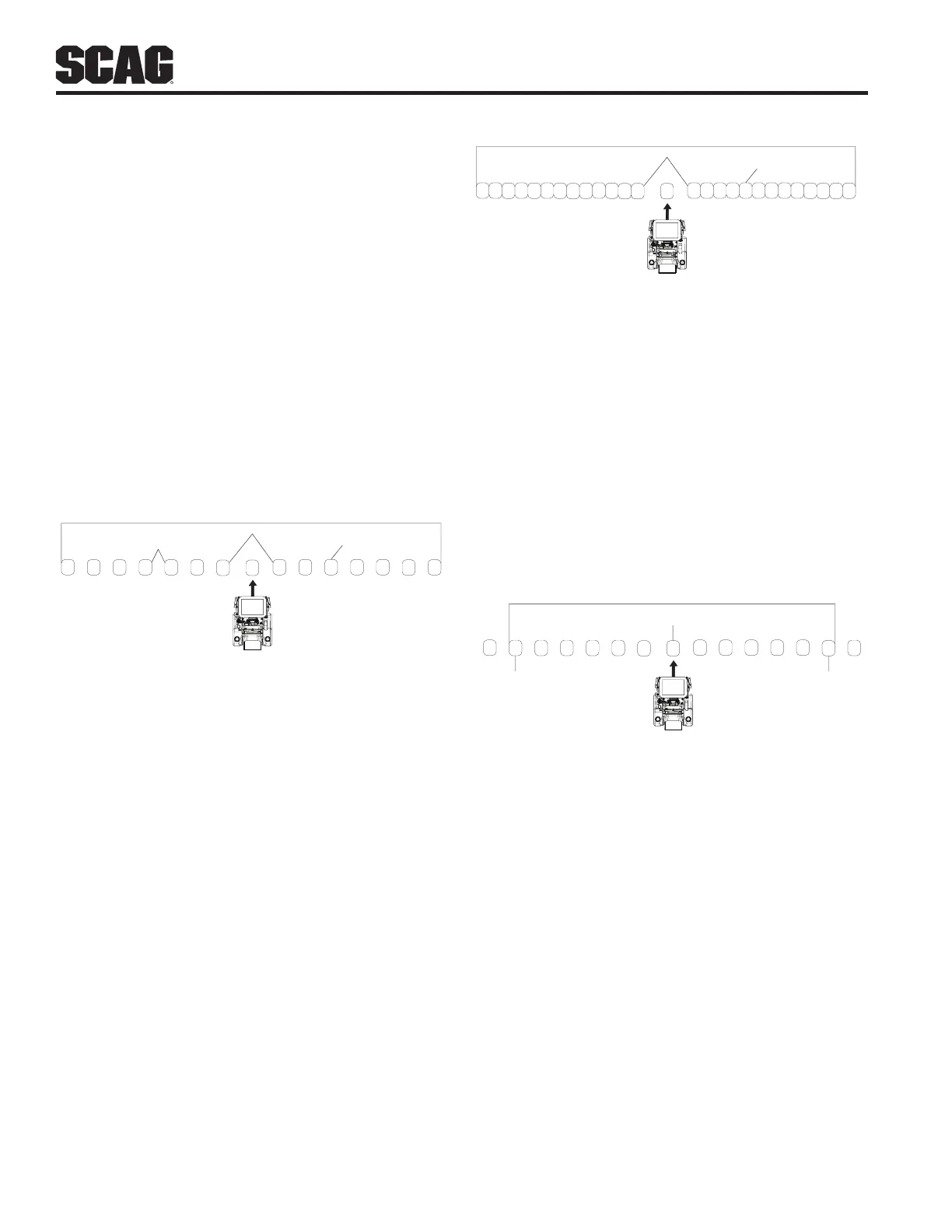

To determine the effective spread width for small granular

items you will need 27 small pans (1ft², 1 or 2 inches high).

Arrange 13 pans to the right (no gap), 13 pans to the left

(no gap), and 1 pan in the center. Make sure to allow room

for the machine to drive between the 13 pans on the left

and the 13 pans on the right, with the center pan placed so

it will miss the drive tires and go underneath the machine

during the pass. See Figure 5-10

- NOTE -

Give the machine plenty of room to make the pass.

Operate the machine at "application" speed while

making the pass. Activate the spreader with ample

time to create a consistant path before getting to

the pans.

CL1 R1 R10R2 R8R3 R9R5 R12R4 R11R6 R13R7L2L8 L3L10 L4L9 L5L11L12 L6

L7

Machine Width (+2 Inches on each side)

Pan (1’x1’x2”)

About 29 Feet

Figure 5-10. Small Granular Material

7. Each pan's material should then be measured and

recorded. The effective spread width is determined by

taking these measurements and finding which pan on

each side has half of what the center pan has. (EX. If

the center pan has 16 ounces, and the 6th pan away

from the machine on each side has 8 ounces. The

effective spread width would be the distance between

the outside of the pan with 8 ounces on the left to the

outside of the pan with 8 ounces on the right.) See

Figure 5-11. If the path is not equal on each side, adjust

the diffuser control, and repeat the procedure until the

spread pattern is even on each side.

CL1 R1 R2 R3 R5R4 R6 R7L2L3L4L5L6L7

16 Ounces

Eective Spread Width

8 Ounces

8 Ounces

Figure 5-11. Measuring Effective Spread Width

Example

- NOTE -

For less accurate spread width, the pattern can

be aligned by using a cone on each side of the

spreader, adjust the pattern so the material barely

hits both cones with both cones equal distance

from the spreader. Measure the distance between

the two cones.

8. The next step is to establish the desired application

rate. Refer to the chemical manufacturer's

recommendations for application rate (lbs/1000 ft²).

Loading...

Loading...