#SC 40RT 06 – 101027 Page 13 of 44

7. Operation

7.1. Starting Up

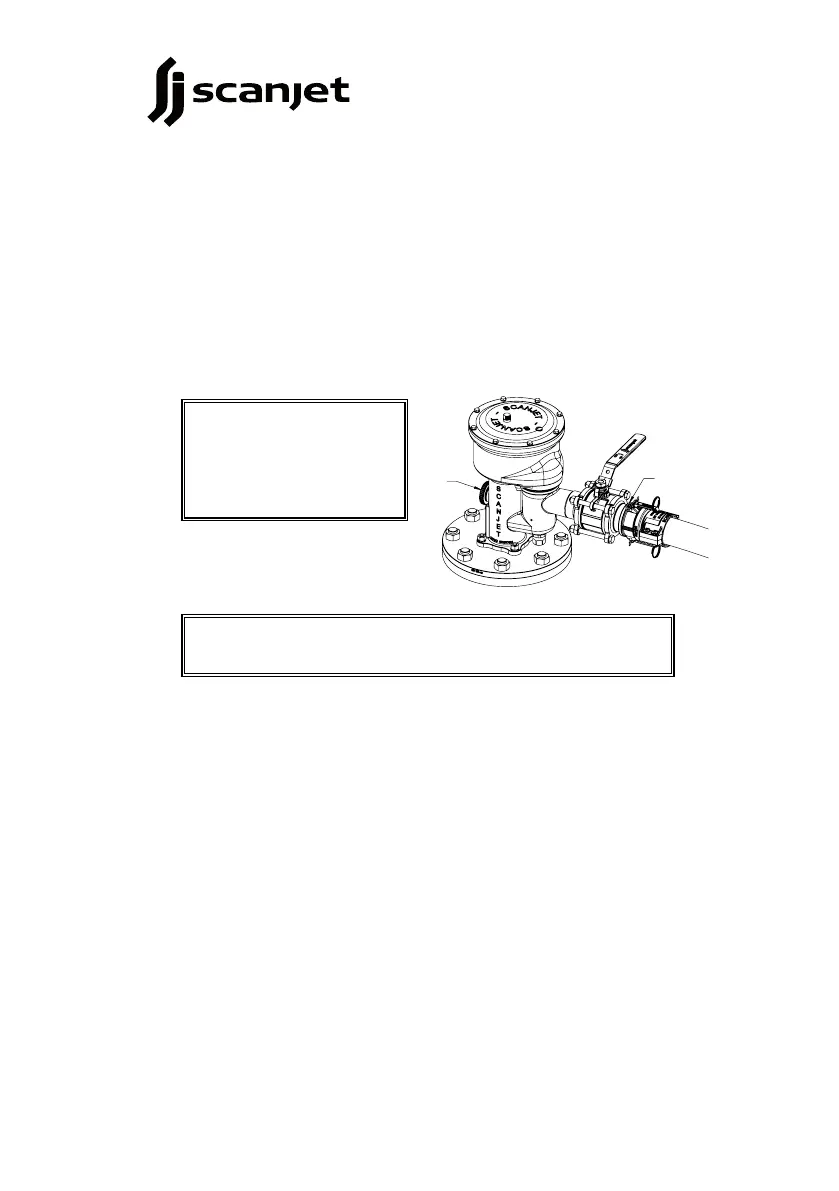

1. Check strainer for free flow, remove all particles (A)

2. Remove protective cover. Remove the drainage plug under the drive unit

and drain it

3. Open the inlet valve (A) slowly to start the machine

4. Make sure the top nut is rotating,

check through the cofferdam (B)

5. Remount the cofferdam plug

7.2. Cleaning Procedure for Solidifying Cargoes

• During transport of cargo, sediments might be created in the bottom of the

tank. The tank cleaning machine must be blown with air/nitrogen.

• Start the tank cleaning machine at low pressure and make sure it is rotating.

Let the machine slowly rotate one revolution, check the top nut through the

cofferdam.

• Raise the pressure to working pressure.

NOTE! If the machine is

started to fast, the magnetic

coupling will release and the

valve must be completely

closed prior to restart

B

A

Designer

Date

Date

Drawer

Surface treatment

Weight

Note

Dimension

Material

General Tolerances

Tolerance ISO 2768-m

Gen. surface

N9

This document is our property and shall not without our

permission in writing be altered, copied, used for manu-

facturing or communicated to any person or company.

Drawing no. / Ritningsnr.

Format

SC40RT

A4

Scale

SC40RT

1:5

SC40RT

Denna handling är vår egendom och får ej utan vårt

skriftliga medgivande ändras, kopieras, användas för

tillverkning eller delges annan person eller firma.

SS-ISO 2768-m for machined parts

(30)-120=

0.3

0.5-3=

0.1 (120)-315=

0.5

(3)-30=

0.2 315)-1000=

0.8

P03.1

Törnedalsgatan 1, 275 21 Sjöbo

SWEDEN

ML

Revision

05-04-19

E

No.

Revision note

Date

Sign.

Qty.

Ins.

gram

NOTE! Watch hands and eyes when removing the cofferdam plug

in case of leakage, use protection goggles and gloves

Loading...

Loading...