#SC 40RT 06 – 101027Page 6 of 44

3. General Description

Cleaning media comes from the supply line and enter through the inlet housing,

passing over a turbine which drives the drive unit via a magnetic coupling,

continue through the main pipe to the nozzle and then out in the tank.

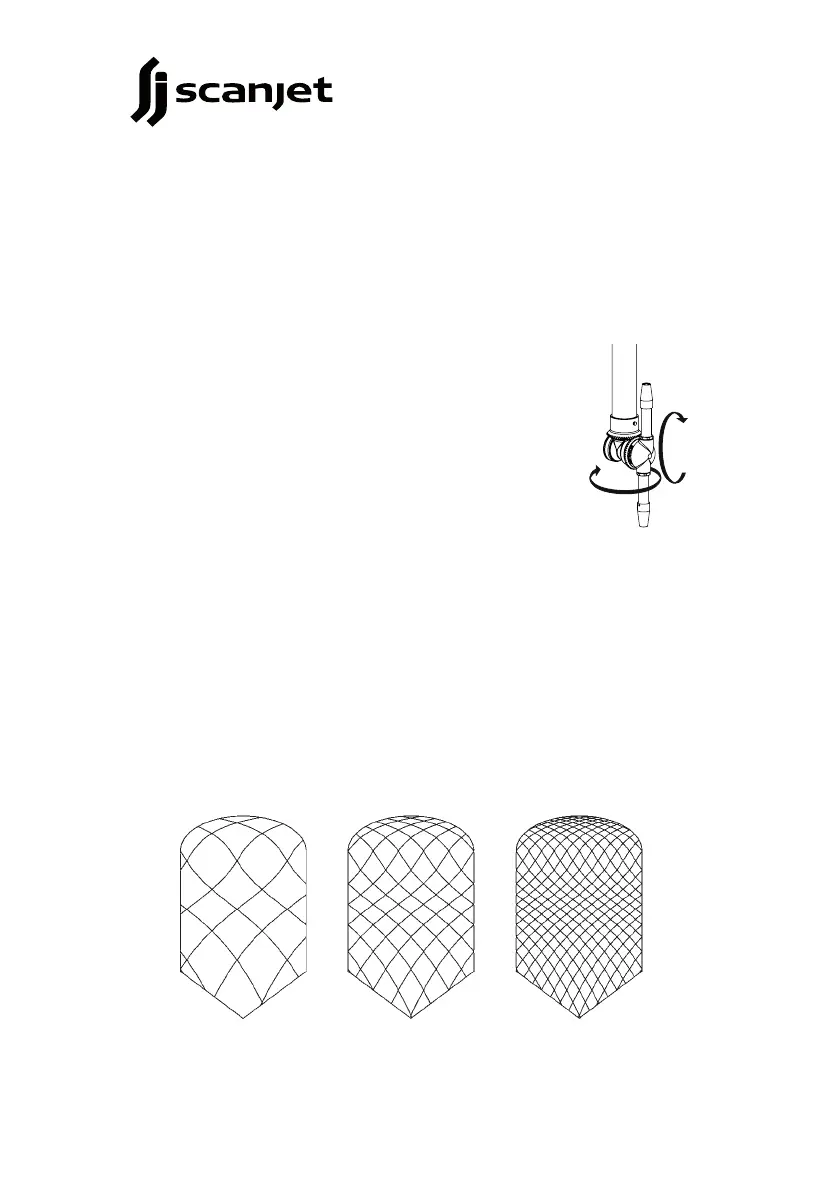

The drive unit will rotate a shaft inside the machine, the

turning shaft. The turning shaft is connected to the bottom

housing that rotates the nozzles via a gear system. The

nozzles will hereby clean the tank in a criss-cross pattern.

The rotation speed is controlled by the rotation speed of

the turbine and could easily be set to desired speed, see

“7.7. Speed Adjustment” on page 20.

The rotations of the nozzles are indicated on the top nut

visible through the cofferdam or on the top shaft on top

of the drive unit.

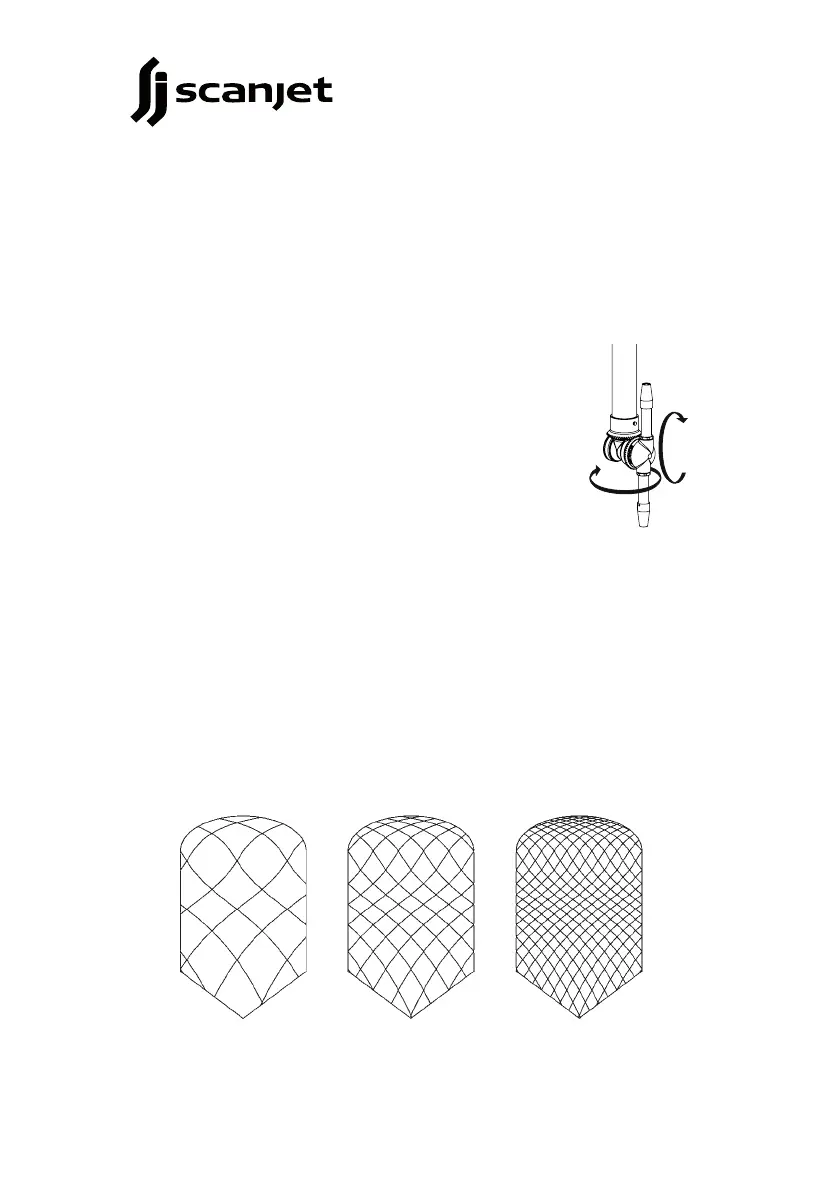

The rotating nozzles will create a cleaning pattern as per

below on the vertical tank-walls. After one cycle a cleaning

pattern will be created as per fig 1. After four cycles the

pattern will be completed as per fig 2. After this the

pattern will be repeated.

A full pattern is created when the main body has rotated 47 turns. With a

rotation speed of 2 rpm will a full pattern take approx. 23,5 min. Note that the

time is depending on the actual setting of the turbine and water pressure. One

cycle will take about 6 minutes.

Cleaning of tanks is a process depending on a number of factors; the soilage of

the tank, distance to tank walls, cleaning procedure and cleaning agent. All these

factors are deciding for the number of cycles that needs to be run.

Fig 1. After one cycle Fig 2. Full pattern

Designer

Date

Date

Drawer

Surface treatment

Weight

Note

Dimension

Material

General Tolerances

Tolerance ISO 2768-m

Gen. surface

N9

This document is our property and shall not without our

permission in writing be altered, copied, used for manu-

facturing or communicated to any person or company.

Drawing no. / Ritningsnr.

Format

SC40RT

A4

Scale

SC40RT

1:7

SC40RT

Denna handling är vår egendom och får ej utan vårt

skriftliga medgivande ändras, kopieras, användas för

tillverkning eller delges annan person eller rma.

SS-ISO 2768-m for machined parts

(30)-120=

0.3

0.5-3=

0.1 (120)-315=

0.5

(3)-30=

0.2 315)-1000=

0.8

P03.1

Törnedalsgatan 1, 275 21 Sjöbo

SWEDEN

ML

Revision

05-04-19

E

No.

Revision note

Date

Sign.

Qty.

Ins.

SC40RT

gram

Loading...

Loading...