#SC 40RT 06 – 101027Page 24 of 44

• Make a complete survey of

the dun unit below deck

- Inspect nozzle and flow

guides so no particles are

stacked

- Inspect the bearings at the

nozzle housing

- Change parts if particles

are stacked in the bearings

or if bearings are worn out.

• NOTE! When replacing old

bearings (pos. 131) at the

nozzle housing, the thrust

bearing (pos. 130) should be

screwed in by hand to finger tight position and then unscrew ½-¾ turn

prior to fit the splitpin (pos. 129). This is important to get the correct

clearance for flushing the bearings during cleaning.

• A service card is included with this manual; see page 43. This should be

completed each time service is performed on your tank cleaning machine

to maintain a proper record/

history.

Every 24 month or every 300h

operation, whichever comes

first

• Perform the same inspection

as described above

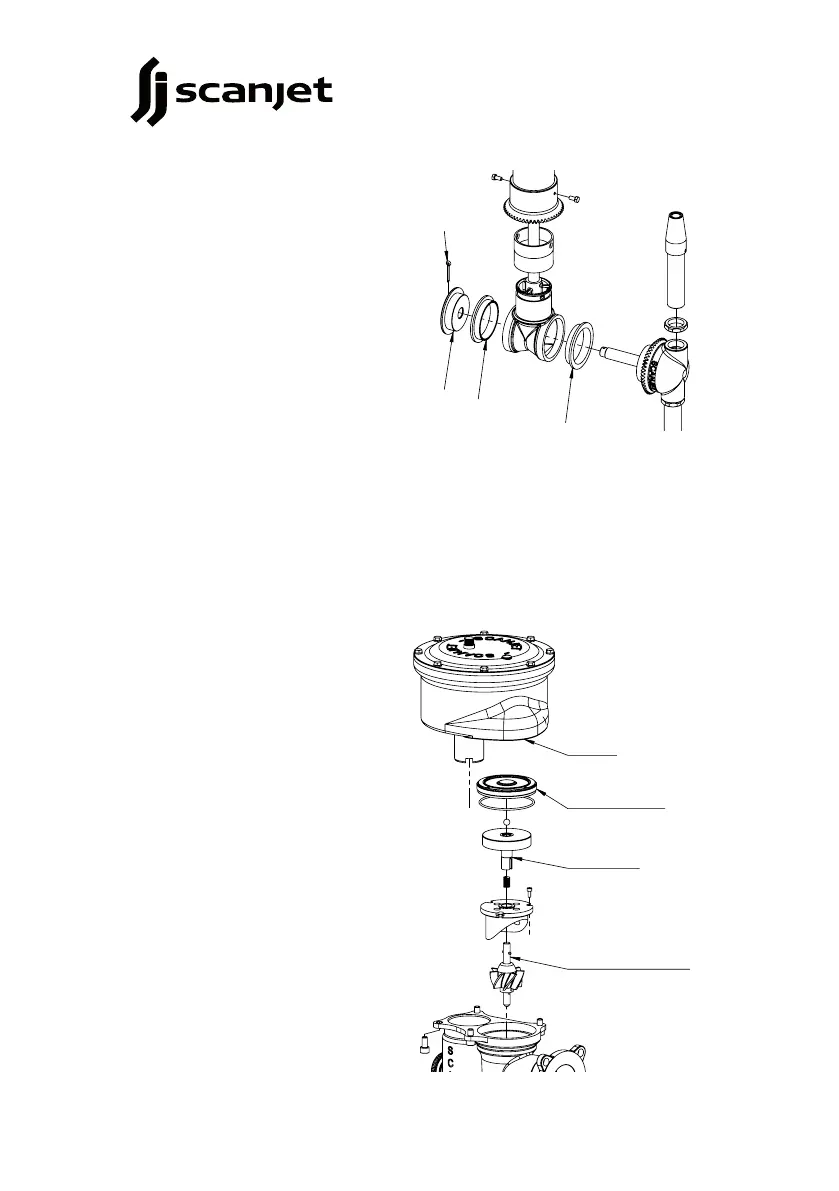

• Also inspect, and change

if necessary, the turbine

shaft (pos. 108) by removing

drive unit and open cover to

magnetic transmission. Check

the upper shaft (pos. 103) and

turbine shaft (pos. 108) for

wear. Change if necessary.

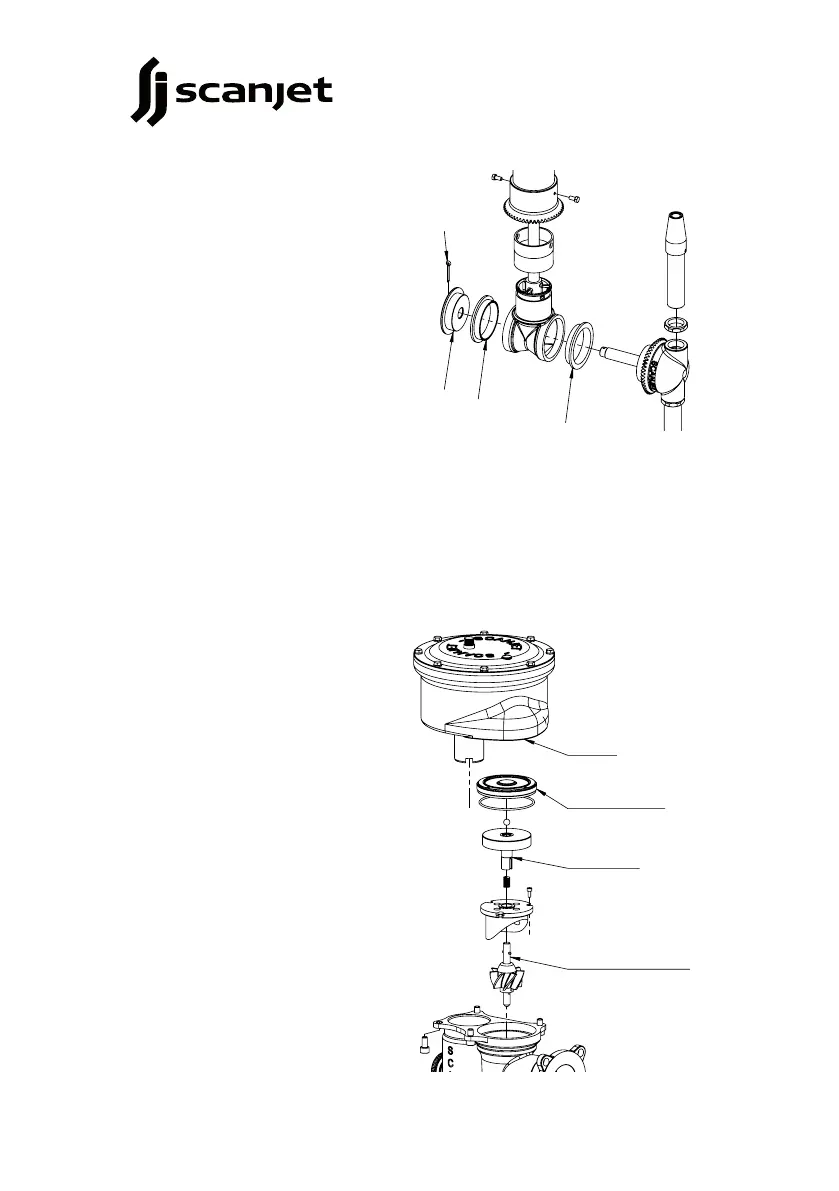

Grease thread

with DEPAC

antiseize grease

Protect!

Upper shaft

(pos. 103)

Turbine/lower shaft

(pos. 108)

Designer

Date

Date

Drawer

Surface treatment

Weight

Note

Dimension

Material

General Tolerances

Tolerance ISO 2768-m

Gen. surface

N9

This document is our property and shall not without our

permission in writing be altered, copied, used for manu-

facturing or communicated to any person or company.

Drawing no. / Ritningsnr.

Format

SC40RT

A4

Scale

SC40RT

1:5

SC40RT

Denna handling är vår egendom och får ej utan vårt

skriftliga medgivande ändras, kopieras, användas för

tillverkning eller delges annan person eller firma.

SS-ISO 2768-m for machined parts

(30)-120=

0.3

0.5-3=

0.1 (120)-315=

0.5

(3)-30=

0.2 315)-1000=

0.8

P03.1

Törnedalsgatan 1, 275 21 Sjöbo

SWEDEN

ML

Revision

05-04-19

E

No.

Revision note

Date

Sign.

Qty.

Ins.

gram

129

131

130

131

Designer

Date

Date

Drawer

Surface treatment

Weight

Note

Dimension

Material

General Tolerances

Tolerance ISO 2768-m

Gen. surface

N9

This document is our property and shall not without our

permission in writing be altered, copied, used for manu-

facturing or communicated to any person or company.

Drawing no. / Ritningsnr.

Format

A4

Scale

1:5

Denna handling är vår egendom och får ej utan vårt

skriftliga medgivande ändras, kopieras, användas för

tillverkning eller delges annan person eller rma.

SS-ISO 2768-m for machined parts

(30)-120=

0.3

0.5-3=

0.1 (120)-315=

0.5

(3)-30=

0.2 315)-1000=

0.8

Törnedalsgatan 1, 275 21 Sjöbo

SWEDEN

Revision

E

No.

Revision note

Date

Sign.

Qty.

Ins.

gram

Loading...

Loading...