M3 x 25mm screws and washers provided, fasten the front of the skid case to

the trolley base.

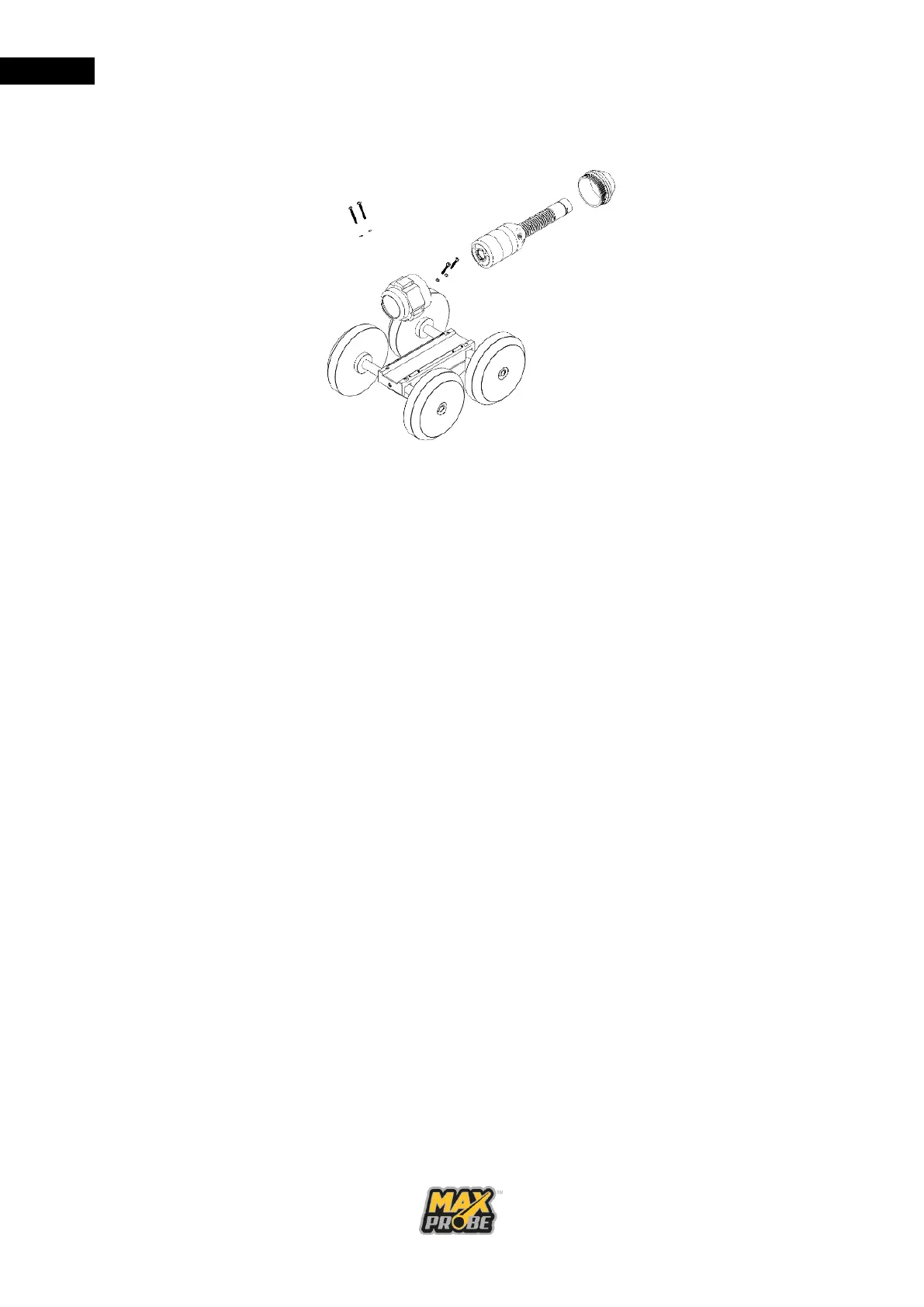

Figure 24: Fitting Camera to Trolley

Reconnect the camera head to the pushrod, being careful not to overtighten the

connector. Position the camera head inside the skid case and screw the rear of

the skid case into the front case by hand. Once tightened, ensure that the

camera head rotates freely inside the skid case before placing the trolley in the

pipeline.

b. Removing the Camera Trolley

Unscrew the rear of the skid case from the front case by hand. Remove the

camera from the front case. Disconnect the camera head from the pushrod and

remove the rear of the skid case from the camera.

Unscrew the front section of the skid case from the trolley base, retaining the

M3 x 25mm screws and washers for reuse. Screw the rear of the skid case to

the front of the skid case, ensuring the O-ring is still present.

c. Trolley Wheel Sets

The trolley mount is supplied with two wheel sets. The smaller wheel set is for

surveying 150mm diameter pipes, while the larger set is for surveying 225mm

and 300mm diameter pipes.

Each set of wheels have their own axles. Attach the wheels using the nut and

washers supplied then attach the axels to the trolley using the two socket screws

supplied.

The trolley is supplied with the additional ballast weight fitted to the trolley with

socket screws. This increased weight is not always necessary, but it helps

stabilise the trolley when using the larger wheels in bigger pipelines. The weight

must be removed when using the smaller wheels to provide enough clearance.

Loading...

Loading...