16 Important!

– For your own safety you must only use the ac-

cessories and additional units listed in the oper-

ating instructions or recommended or specied

by the manufacturer. The use of mounted tools

or accessories other than those recommended

in the operating instructions or catalogue may

place your personal safety at risk.

17 Noise

– Wear ear muffs when you use the compressor.

18 Replacing the power cable

– To prevent hazards, leave the replacement of

damaged power cables strictly to the manufac-

turer or a qualied electrician. There is a risk of

electric shock!

19 Inating tires

– Directly after inating tires, check the pressure

with a suitable pressure gauge, for example at

your lling station.

20 Roadworthy compressors for building site opera-

tions

– Make sure that all lines and ttings are suitable

for the maximum permissible operating pressure

of the compressor.

21 Place of installation

– Set up the compressor on an even surface.

22 Supply hoses at pressures above 7 bar should be

equipped with a safety cable (e.g. a wire rope).

ADDITIONAL SAFETY INSTRUCTIONS

Safety instructions for working with compressed

air and blasting guns

• The compressor pump and lines can become very hot

during operation. Touching these parts will burn you.

• The air which is sucked in by the compressor must be

kept free of impurities that could cause res or explo-

sions in the compressor pump.

• When releasing the hose coupling, hold the hose cou-

pling piece with your hand. This way, you can protect

yourself against injury from the rebounding hose.

• Wear safety goggles when working with the blow-out

pistol. Foreign bodies or blown off parts can easily

cause injuries.

• Do not blow at people with the blow-out pistol and

do not clean clothes while being worn. Risk of injury!

Safety information for paint spraying

• Do not process any paints or solvents with a ash

point below 55° C. There is a risk of explosion!

• Do not heat up paints or solvents. There is a risk of

explosion!

• If hazardous liquids are processed, wear protective

lter units (face guards). Also, adhere to the safety

information provided by the manufacturers of such

liquids.

• The details and designations of the Ordinance on

Hazardous Substances, which are displayed on the

outer packaging of the processed material, must be

observed.

• Additional protective measures are to be undertak-

en if necessary, particularly the wearing of suitable

clothing and masks.

• Do not smoke during the spraying process and/or in

the work area. There is a risk of explosion! Paint va-

pors are easily combustible.

• Never set up or operate the equipment in the vicin-

ity of a re place, open lights or sparking machines.

• Do not store or eat food and drink in the work area.

Paint vapors are harmful to your health.

• The work area must exceed 30 m

3

and sufcient ven-

tilation must be ensured during spraying and drying.

Do not spray against the wind. Always adhere to the

regulations of the local police authority when spray-

ing combustible or hazardous materials.

• Do not process media such as white spirit, butyl al-

cohol and methylene chloride with the PVC pressure

hose. These media will destroy the pressure hose.

Operating pressure vessels

• You must keep your pressure vessel in good work-

ing order, operate the vessel correctly, monitor the

vessel, carry out necessary maintenance and repair

work immediately and meet the relevant safety pre-

cautions.

• The supervisory authority may enforce essential con-

trol measures in individual cases.

• A pressure vessel is not allowed to be used if it has

faults or deciencies that can endanger workers or

third parties.

• Check the pressure vessel for signs of rust and dam-

age each time before using. Do not use the compres-

sor with a damaged or rusty pressure vessel. If you

discover any damage, then please contact the cus-

tomer service workshop.

Do not lose these safety instructions

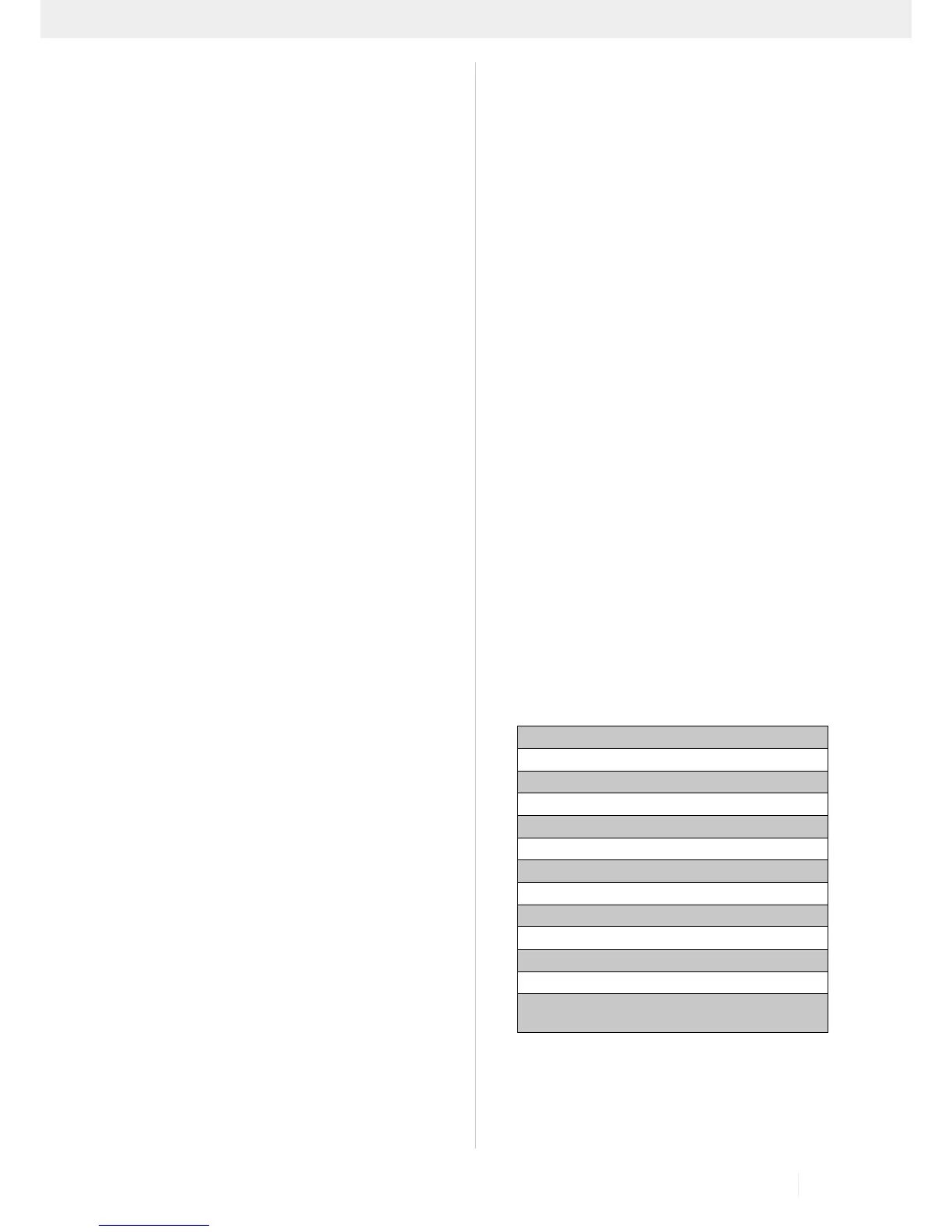

6. Technical data

Mains connection

230 V ~ 50 Hz

Motor rating W

2200

Operating mode

S1

Compressor speed

2850 min

-1

Pressure vessel capacity (in liters)

50

Operating pressure

approx. 10 bar

Theoretical intake capacity (l/min)

approx. 412

sound power level L

WA

97 dB(A)

uncertainty K

WA

2,03 dB

Protection type

IP20

Weight of the unit in kg

approx. 44,5

Oil (15W 40) l

approx. 0,25

Max. altitude

(above mean sea level)

1000 m

The noise emission values were measured in ac-

cordance with EN ISO 3744.

Wear hearing protection.

The effects of noise can cause a loss of hearing.

Loading...

Loading...