www.scheppach.com

36

|

GB

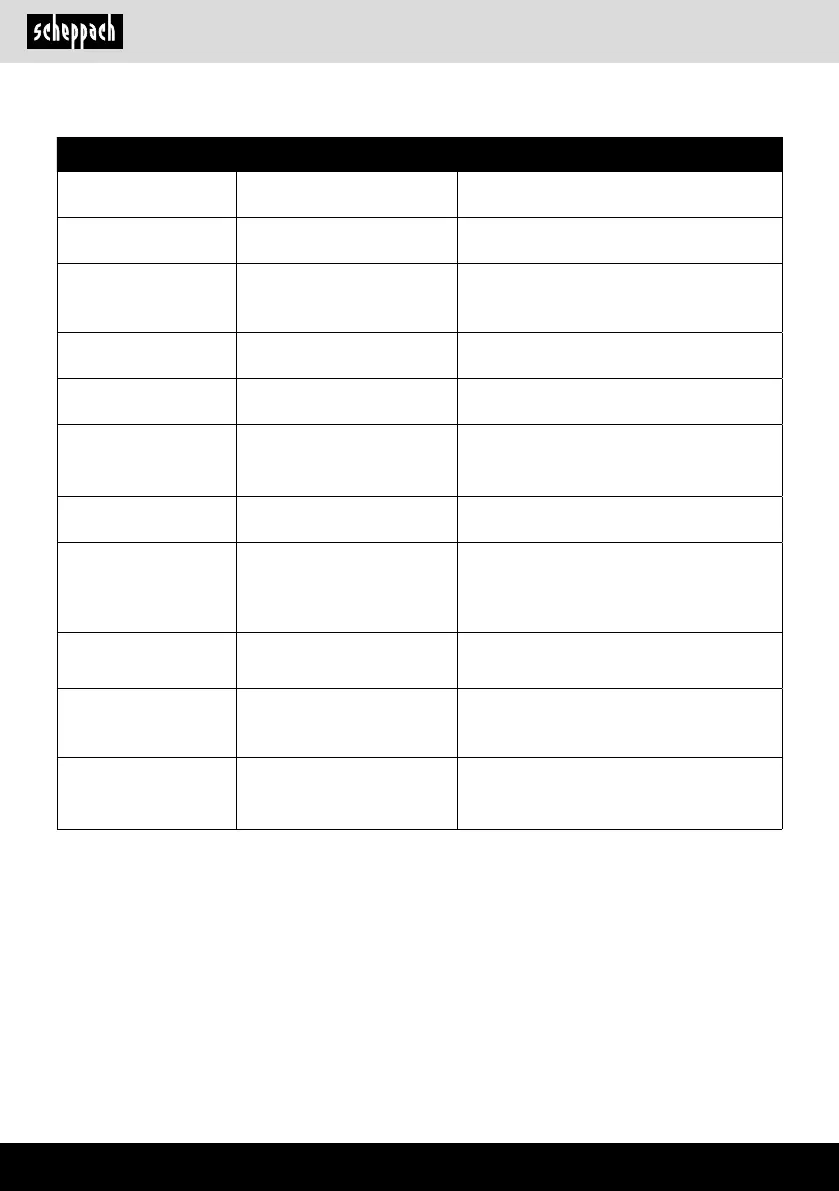

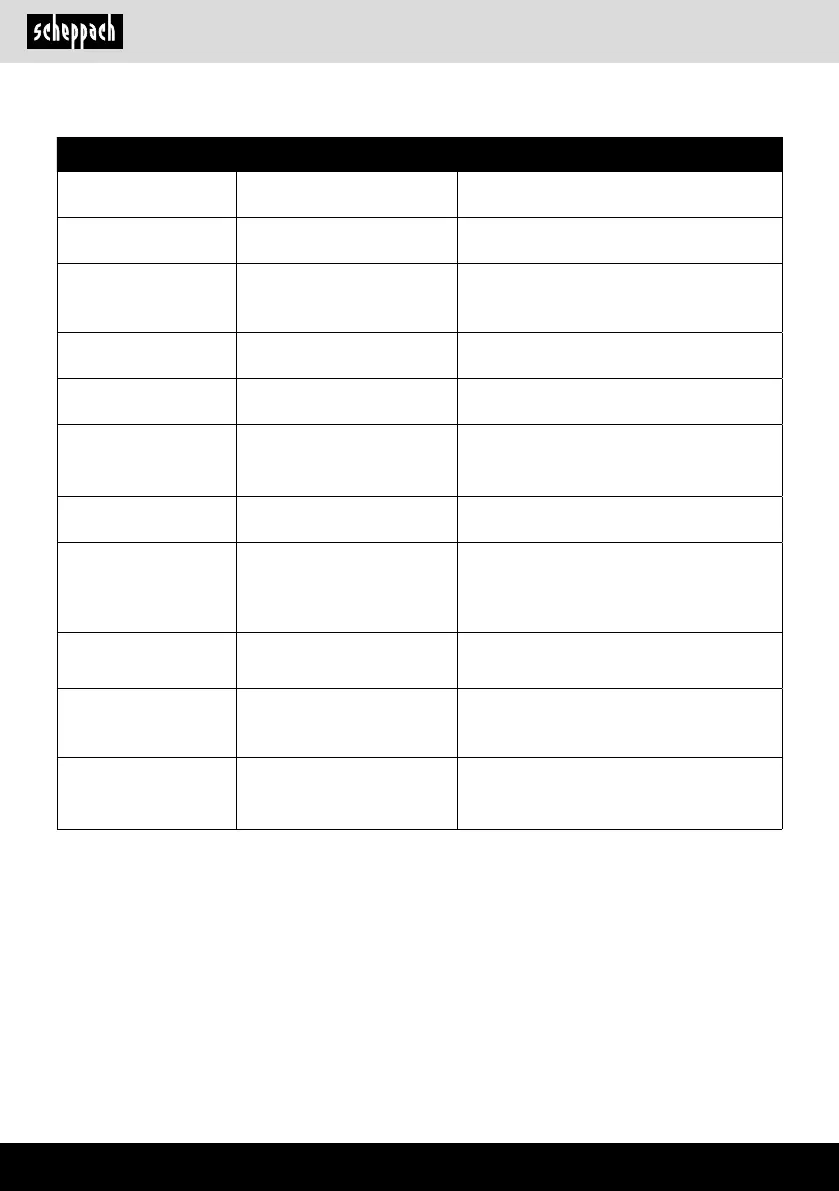

17. Trouble shooting

Problem Possible Cause Remedy

Machine cannot be

switched on.

• No power supply.

• Carbon brush worn.

• Check power supply.

• Take machine to your service point.

Machine does not work or

stops suddenly.

• Power cut.

• Motor or switch defective.

• Power cut.

• Motor or switch defective.

Machine stops during

planing.

• Planing blade blunt/worn.

• Overload switch has tripped.

• Too much chip removal.

• Replace or sharpen blade.

• Switch on the motor again once it has cooled.

• Reduce chip removal.

Workpiece jams during

thicknessing.

• Cutting depth too great. • Reduce cutting depth and machine the work-

piece in several passes.

Speed decreases when

planing.

• Too much chip removal

• Blunt knives.

• Reduce chip removal.

• Replace knives.

Unsatisfactory surface

nish.

• Planing blade blunt/worn.

• Planing blade lled with chips.

• Uneven feed.

• Replace or sharpen blade.

• Remove chips.

• Feed the workpiece with constant pressure

and at reduced speed.

Machined surface too

rough.

• Workpiece contains too much

moisture.

• Dry workpiece.

Machined surface

cracked.

• Workpiece was machined

against the grain.

• Too much material planed at

one pass.

• Machine the workpiece from the opposite

direction.

• Machine the workpiece in several passes.

Workpiece speed too low

during thicknessing.

• Thicknesser table resinous

• Feed roller too slippery

• Clean and apply glide wax

• Gently scour with sand paper

When thicknessing, chip

ejection obstructed (with-

out dust extractor).

• Too much chip removal.

• Blunt knives.

• Wood too humid.

• Reduce chip removal.

• Replace knives.

• Dry workpiece.

With surface planing and

thicknessing, chip ejection

obstructed (with dust

extractor).

• Suction performance too

weak.

• Use a dust extractor unit having an airow rate

at the suction connection of at least 20 m/s.

Loading...

Loading...