6 Maintenance

Operating Instructions for Actuators Type AB with Control Unit

OM-ENGLISH-ABCSC.V1.2-16xx-V2.02-2023.04.27

Figure 42

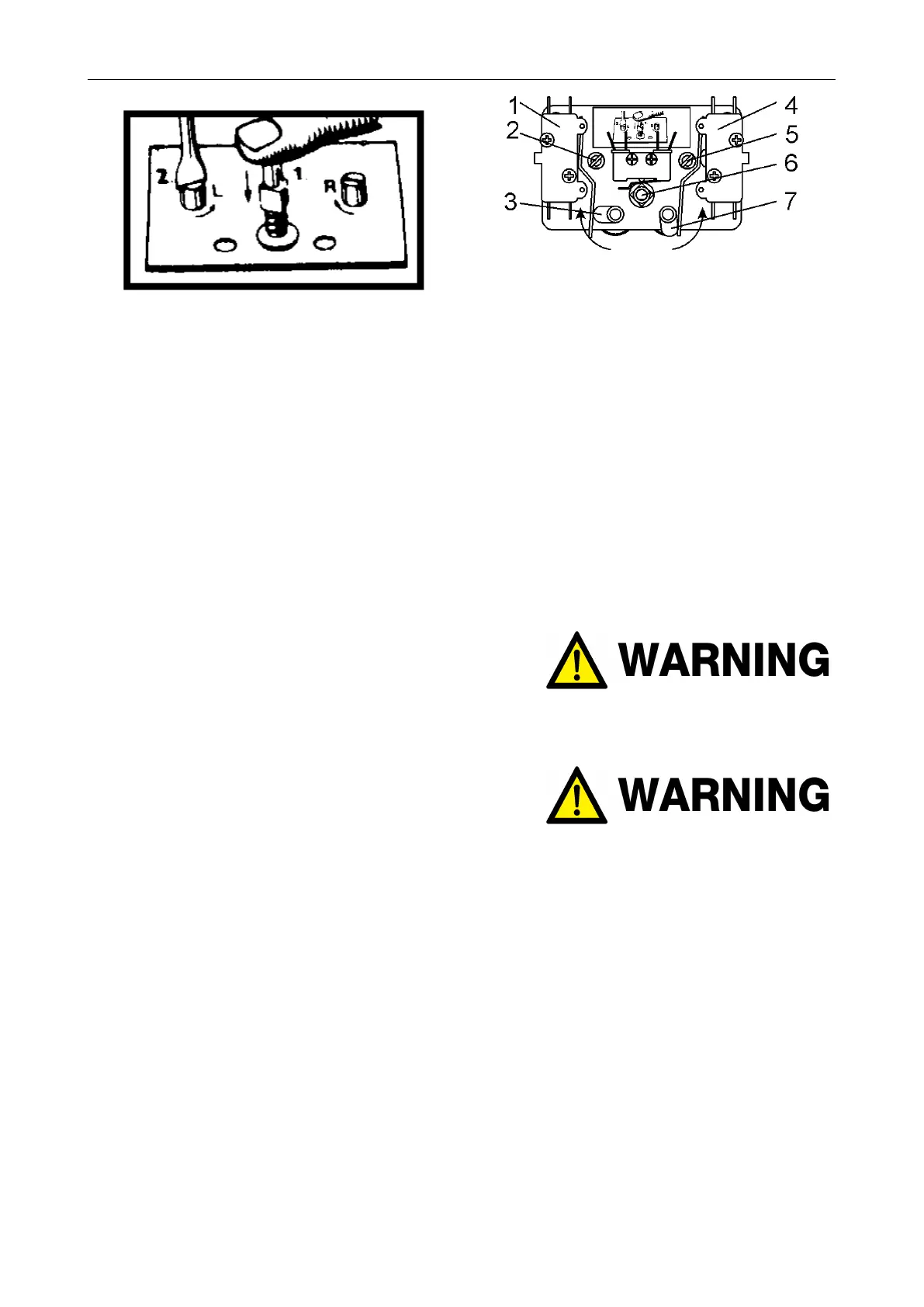

Figure 43: 1. . . switch S4, 2. . . L, 3. . . trip cam for

counter-clockwise (OPEN), 4. . . switch S3,

5. . . R, 6. . . flasher shaft, 7. . . trip cam for

counter-clockwise (CLOSE)

• Setting the position „OPEN“:

Move the actuator into the position „OPEN“by hand. To set the final position, push the flasher shaft with

square cam (see Figure 42) downwards with the finger. Using a screwdriver, turn the slotted shaft of

the “L“rollers in the direction of the arrow, until the corresponding clockwise trip cam activates the travel

switch (see Figure 43). Release flasher shaft and be sure that the toothed roller locks in.

5.10 Final works

Following commissioning, check for proper sealing the covers to be closed and cable inlets. (see section 2.4,

page 7) Check actuator for paint damage (by transport or installation) and repair if necessary.

6 Maintenance

WARNING: Maintenance work on open actuators may only be

conducted if these are de-energized. Reconnection during

maintenance is strictly prohibited.

WARNING: Work on the electrical system or equipment must

be carried out only in accordance with electrical regulations

by a qualified electrician himself or by specially instructed

personnel under the control and supervision of a qualified

electrician.

Actuators are ready for use after installation. By default, the actuator is delivered filled with grease.

On-going monitoring:

• Beware of increased running noise. During long downtime periods, operate the actuator at least every 3

months.

• For actuators with output types A, B and C according to DIN 3210-A, B1, B2 and C according to DIN ISO

5210, re-lubricate at least every 6 months on existing grease fittings (see section 10.3, page 26)

Actuators are designed for installation in any position (see section 2.5, page 7). Therefore, the main body is

not equipped with a level indication or a drain plug.

The replacement of the lubricant from the main body must be performed via the handwheel.

Every approx. 10,000-20,000 hours ( about 5 years - section 10, page 25), depending on the workload,

you must:

• Change oil/grease

22

Loading...

Loading...