Operating Instructions for Actuators Type AB with Control Unit

OM-ENGLISH-ABCSC.V1.2-16xx-V2.02-2023.04.2710 Recommendations of Lubricants (for all manufactures)

10.5 Basic Lubricant Service Interval

On actuator maintenance, the old grease must be removed completely and replaced by a new one.

NOTE: The service interval for Schiebel actuators is 10 years from the date of delivery by Fa. SCHIEBEL

Antriebstechnik Gesellschaft m.b.H, A-1230 Vienna. The functionality and operating life of the lubricants is,

however, dependent upon operational conditions. It may be necessary to take reduction factors into account.

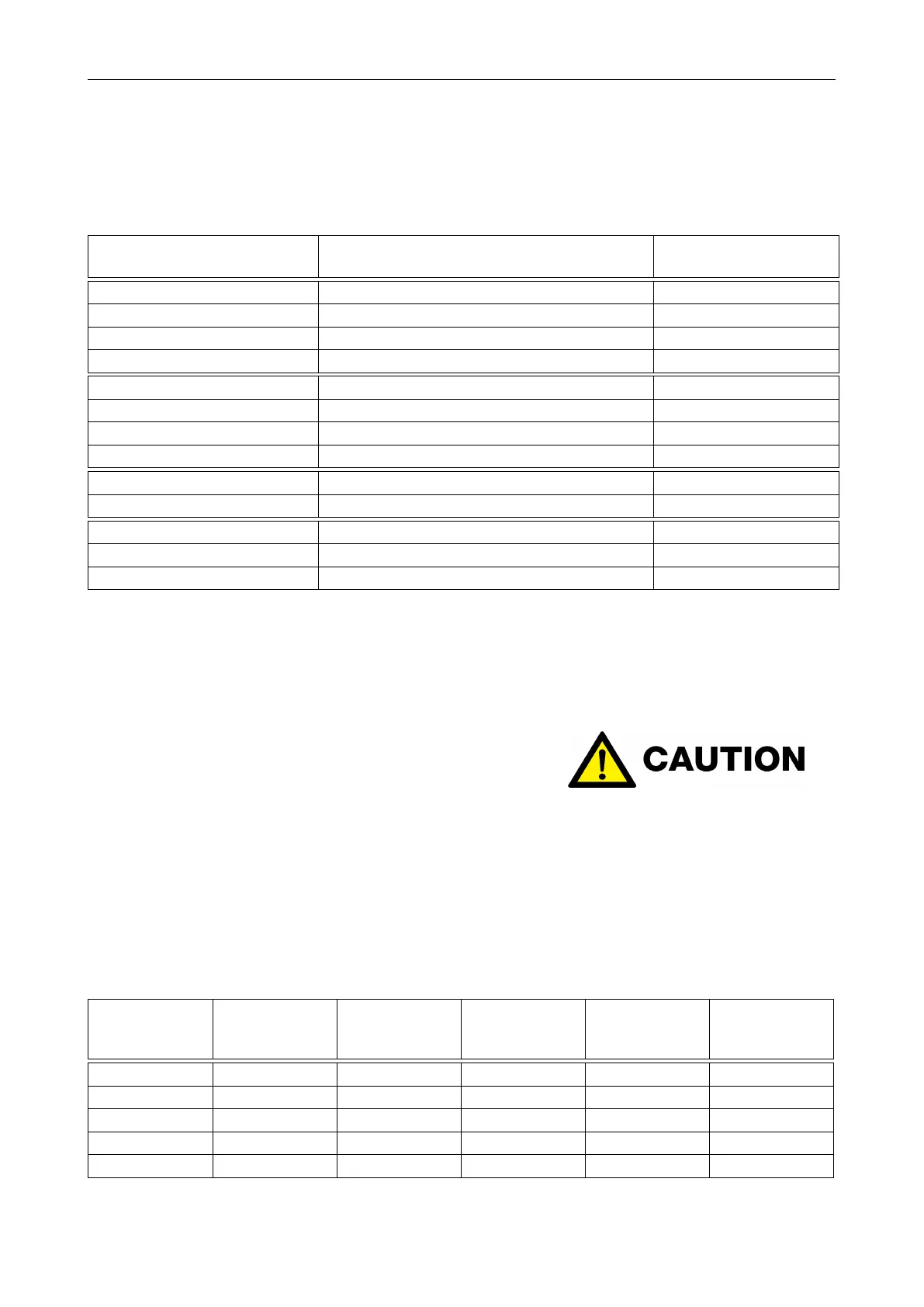

Operational condition(s) Definition

Reduction

Factor(Multiplier)

On-period (OP) (Total of motor running time)

Extremely high OP over 1,250 hours/year 0,5

High OP over 500 hours/year 0,7

Extremely low OP less than 0.5 hours/year 0,8

Ambient temperature (Permanent or long-term)

Extremely changing between -10 and +50°C 0,5

Extremely high over +50°C 0,7

Extremely low below -25°C 0,9

Output speed (at main shaft of actuator)

High revolution over 80 rev./min 0,8

Utilization factor (with respect to nominal performance)

Very high over 90% 0,8

High between 80 and 90% 0,9

Example:

Extremely low OP + extremely low ambient temperature + high revolution + utilization factor 87%

⇒0.8 x 0.9 x 0.8 x 0.9 = 0.51 reduction factor.

Lubricant maintenance interval ⇒ 10 years x 0.51 = 5.1 years (62 months).

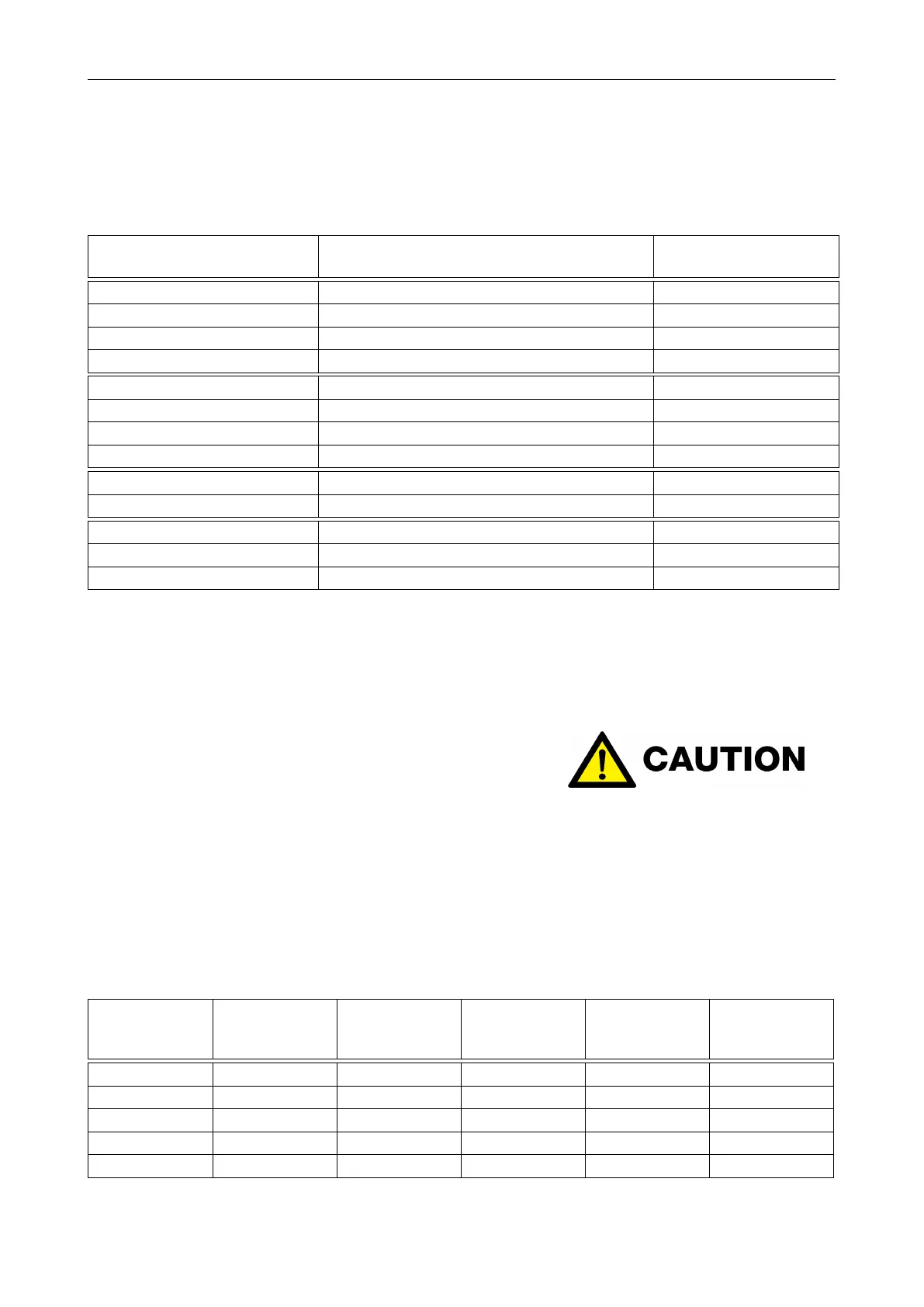

CAUTION: A thusly calculated maintenance interval does not

apply to the maintenance of the output type A (threaded bushing),

nor to the maintenance of the linear and spindle actuator units.

These must be regularly re-greased (at least once every six

months) at the lubricating nipples (see section 10.3, page 26)!

During actuator maintenance, the old lubricants must be thoroughly removed and replaced by fresh ones. No

mixing of different makes of lubricant is permitted!

The quantities needed for lubricant service can be seen from the table below.

10.6 Lubricant Requirements

Type of actuator Main gear Spur gears

Output form A

(Threaded

bushing)

Output form B

(Plug bushing)

Output form C

(Claw coupling)

AB3/5 1kg (1l oil) — 5cm

3

3cm

3

3cm

3

AB8 1kg (1l oil) 1cm

3

5cm

3

3cm

3

3cm

3

AB18 1kg (1l oil) 1cm

3

8cm

3

5cm

3

5cm

3

AB40/80 1,5kg (1,5l oil) 1,5cm

3

9cm

3

6cm

3

6cm

3

AB100/200 3,5kg (3,5l oil) 1,5 kg (1,5l oil) 23cm

3

20cm

3

20cm

3

When lubricating precision components, such quantities of lubricant are to be used as to ensure fine moistening

27

Loading...

Loading...