5

SLC440

Operating instructions

Safety light curtain

EN

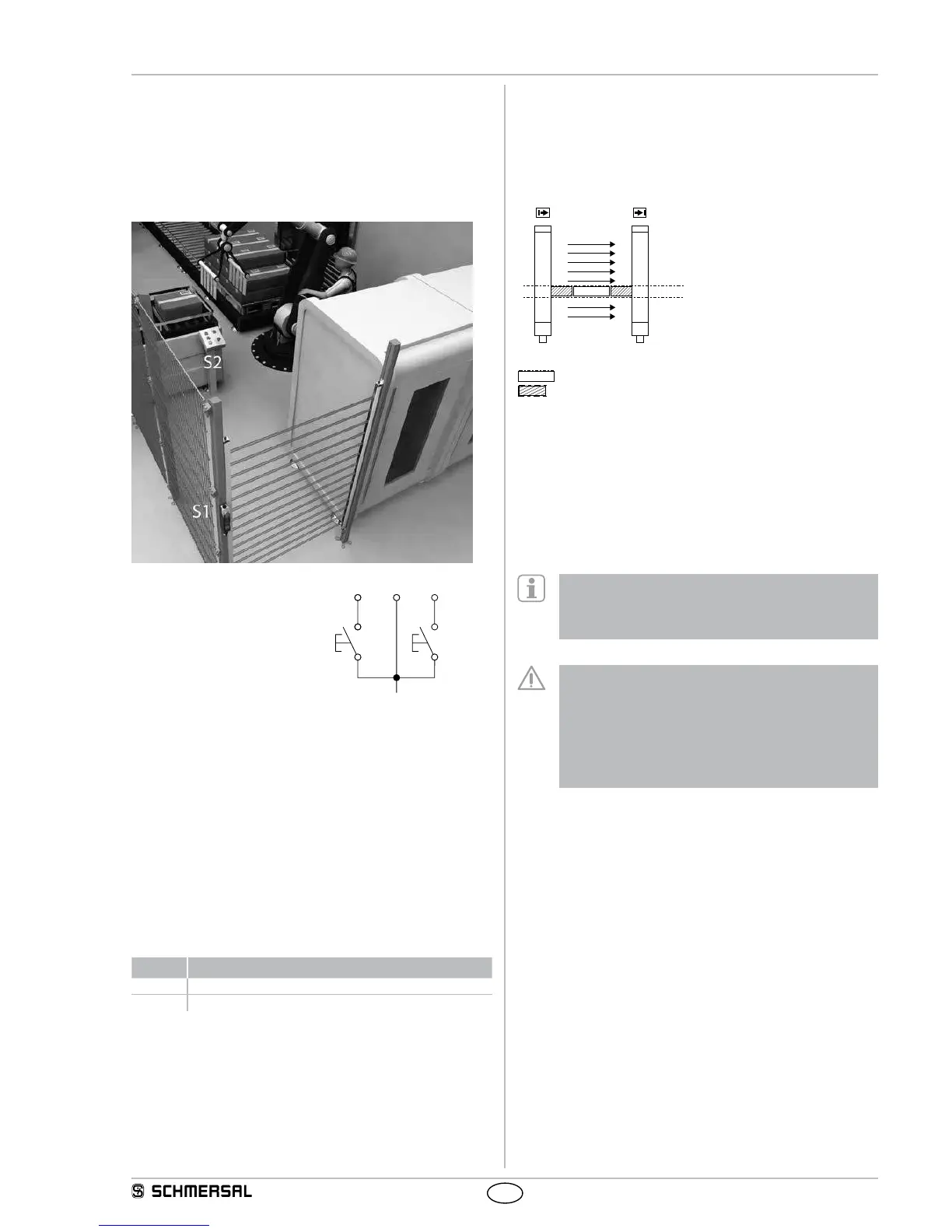

2.8.3 Restart interlock with double acknowledgement/reset

In applications with access monitoring, a complete overview of the haz-

ardous areas is often not possible; despite that, a reset of the command

device for the restart interlock outside of the hazardous area by third

parties is at all times enabled, although possible persons/operators

are in the invisible area. This hazardous situation can be avoided by

means of a double reset, i.e. integration of two command devices inside

and outside the hazardous area.

Wiring of the receiver

- Command device S1 at pin 1

- Command device S2 at pin 5

- Pin 6, no signal (input open)

S1

Specification

The operating mode is available, when the parameter setting -

double reset is activated (P 5). See chapter Parameter setting.

Sequence for enabling:

1) Actuate command device inside of the hazardous area (S2) and

leave the hazardous area

2) Go through protected field or interrupt at least one beam, then

release protected field

3) Actuate the command device outside of the hazardous area (S1)

Command device S1 can be reset (acknowledged) within a timeframe

of 2 to 60 seconds after the actuation of S2. If the order or the time

requirement is not respected, the process must be repeated.

Signaliling: LED restart (yellow)

Status Note

On Release of S2 (restart interlock 2) waiting for signal

Flashing Release of S1 (restart interlock) waiting for signal

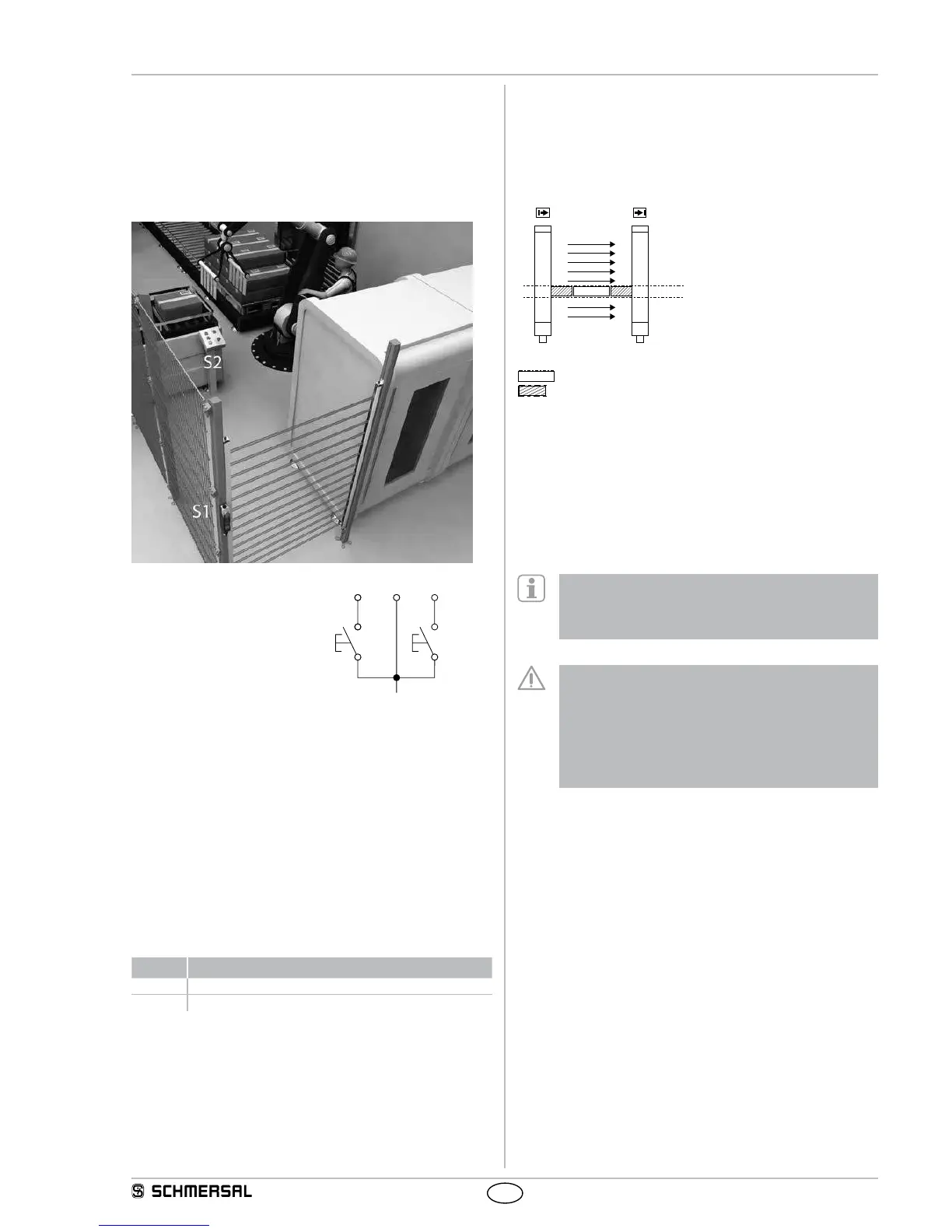

2.8.4 Fixed blanking

The SLC440 can blank stationary objects in the protection field.

Multiple protection field areas can be blanked. If small changes are

made within the fixed blanking area, each time 1 beam can be addition-

ally blanked to increase the tolerance. See chapter Parameter setting

- Fixed blanking with movable edge regions (P 2).

Fixed blanking area

E1 R1

Key

Object in protection field

mechanical cover

The range of the fixed blanking can be arbitrarily chosen in the

protection field.

The first beam line, which realises the optical synchronisation and is

located immediately behind the diagnostic window, cannot be blanked.

The area of the fixed blanking must not be modified after the teach-in

process. Any change of the area or removal of the object from the

protection field will be detected by the system. As a result, the outputs

are disabled (locked). This locking can be neutralised by executing a

new teach-in process in accordance with the actual beam interruptions.

The function is activated by means of the parameter setting

(P1). If the function is activated, the LED blanking in the

diagnostic window of the receiver starts flashing.

See chapter Parameter settings.

The remaining lateral areas must be protected against

intrusion by means of mechanical covers.

The lateral covers must be fixed with the object.

Partial covers are not authorised.

After the fixed blanking, the protection field must be tested

by means of the test rod.

The restart interlock function of the safety light curtain

or the machine must be activated.

2.8.5 Fixed blanking with movable edge region

This function can compensate slight position changes of one fixed

blanked object with a change of ± 1 beam. This position change cor-

responds to an amplitude of approx. ± 10 mm resolution 14 mm and

approx. ± 20 mm resolution 30 mm upwards and downwards in the

protection field.

Loading...

Loading...