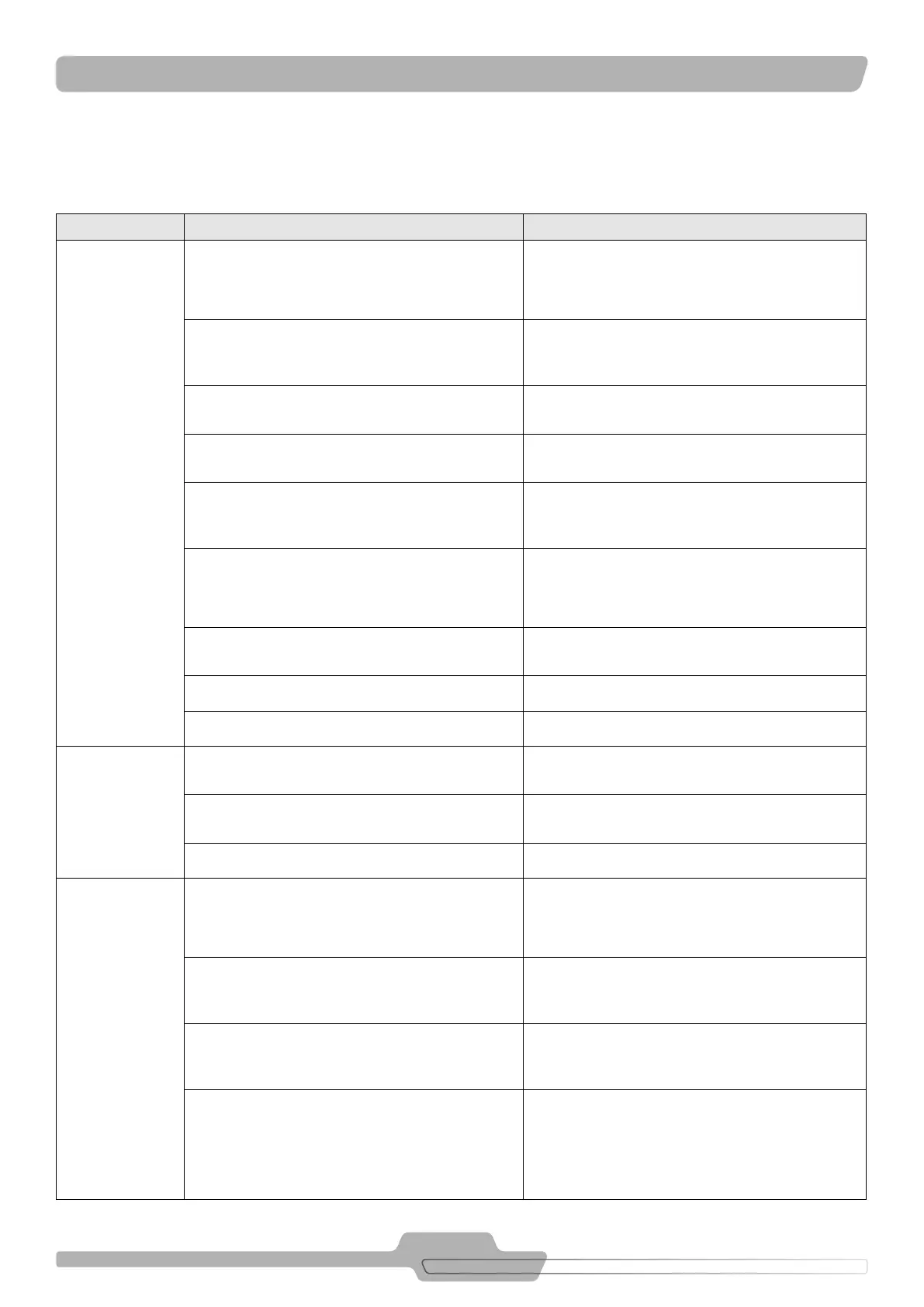

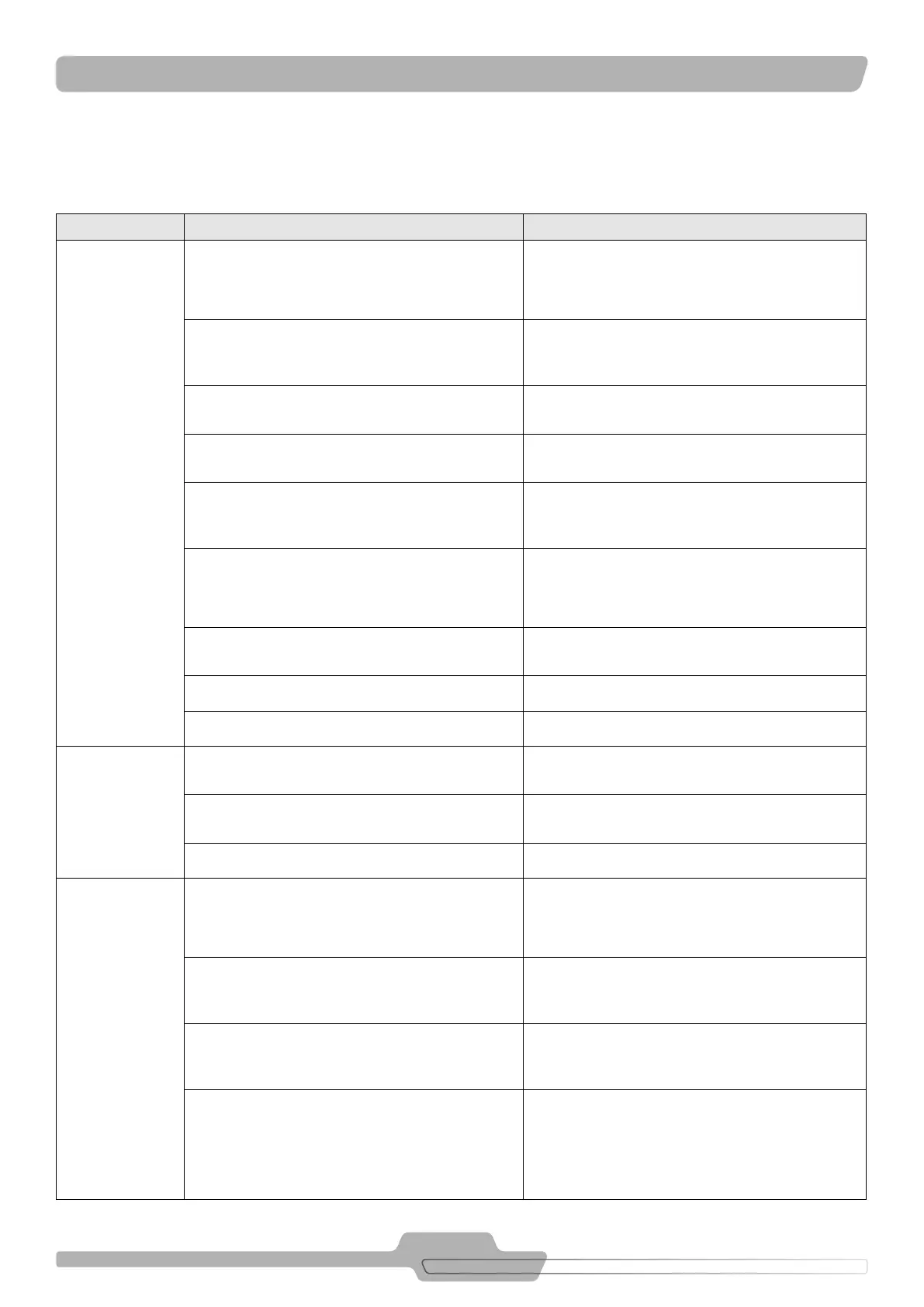

114

The purpose of this list of procedures is to simulate the most common problems and possible causes which may cause downtime or im-

proper operation of your SRS - Air Dryer.

The simplicity of some procedures for troubleshooting provides the means for the user to solve some of them without the interaction of

specialized Technical Assistance. Therefore, if problems persist after applying the listed corrective actions, get in touch with technical as-

sistance from an accredited Schulz Authorized-Technical/Distributor for this equipment.

EVENTUAL DEFECT PROBABLE CAUSE SOLUTION

The

compressed

air does not

dry (humidity

is present in

the line).

Needle valve is closed.

The condenser outlet from the air dryer is blocked,

flooding the heat exchanger and allowing the swept overflow to

enter the compressed air network.

Check if the needle valve of the drain is sufficiently open. If not,

turn the valve handle counter clockwise to increase the

condensate flow during drain. It is not necessary to open the

valve completely, just as much

as necessary.

The drain system is blocked by dirt.

The presence of dirt or particles in the purge system can block the

condensate flow.

Depressurize and deenergize the dryer. After that,

disassemble the drain system and clean it, then reassemble it.

If any doubts arise on how to perform the cleaning process,

get in touch with the Schulz Authorized Dealer.

Solenoid valve of the drain does not work.

The solenoid valve piston drags or the coil is burned so the

component does not function.

Get in touch with Schulz

Authorized-Technical/Distributor.

High temperature of compressed air.

Air Temperature in the input line to the dryer is extremely high (over

38°C) that is over the cooling capacity of the equipment.

Check the output temperature from the air compressor.

Perform the cleaning of the radiator or after cooler

(if present).

High room temperature.

Room temperature is very high (over 38°C),

decreasing the capacity for thermal exchange from the condenser and

harming the efficiency of the air dryer.

Check if the room temperature 38°C. If it is, provide the means

to decrease the temperature. For assistance, get in touch

with Schulz Authorized- Dealer.

Thermal protector for the refrigeration compressor is activated. Refri-

geration compressor is turning off due to very high temperature. The

system does not have enough refrigerant or it is overloaded.

Check if the refrigeration compressor is turning off during

its operation. This is noticed through an increase in

temperature and shows on the digital controller for values over

15°C. If this happens, get in touch with Schulz Authorized Dealer.

Air flow is over the equipment capacity.

The quantity of air supplied to the dryer is

over its capacity.

Get in touch with Schulz Authorized Dealer to check if the air dryer is

correctly dimensioned.

Extra long or very small diameter purge hose.

Difficulty in expelling the condensate from the purge system.

Install hoses with a maximum length of 4 meters and in

internal diameter of a least 5/16”.

A single drain hose for several dryers.

This can interfere with the correct purging of the equipment.

Use separate hoses for each purge system, if there is more

than one dryer installed.

Dryer does

not start

Breaker switch tripped because of short circuit or improper power

supply.

Power supply is short circuited and does not let the dryer activate.

Get in touch with Schulz

Authorized-Technical/Distributor.

Temperature sensor is disconnected, broken, or short-circuited.

In any of these conditions, the electronic controller does not let the

dryer activate.

Check if the electronic controller shows some errors mentioned

on Table 12.1, of this manual. If it shows get in touch

with Schulz Authorized Dealer.

Electronic controller is not set correctly.

This does not let the dryer activate.

Check if the controller “OK” led is lit. If not get in touch with

Schulz Authorized Dealer.

Dryer turns off

for no reason.

It turns off because of the high pressure switch.

If the compressed air temperature to the inlet

of the dryer is very high (over 38°C) excessive increases in

condensate pressure making the high pressure pressostat

activate.

Check if the compressed air temperature is over 38°C. If it is,

provide the means to reduce the temperature. If the system

has a cooler before the dryer check if it too dirty. Get in touch

with Schulz Authorized Dealer.

It was turned off by the high pressure switch.

If the room temperature is very high (over 38°C) the thermal exchange

in the condenser will be harmed and the condenser will

cause high pressure in the pressostat.

If it is, If the room and apply corrective measures to reduce

the temperature and for assistance get in touch with

the Schulz Authorized Dealer.

It was turned off by the high pressure switch. If the condenser is dirty,

the air discharge will be blocked and not allow the heat exchange

with the room temperature and make the condensation

pressure rise.

Clean the condenser as stated

on of this manual.

It was turned off by the high pressure switch.

The fan(s) turn on and off as the equipment needs. This can occur and

the fan remains turned on, but if (it/they) (do /does)not turn on at any

given moment until the dryer turns off for no reason, it is possible

that there is some problem in the electric circuit of the blocked

electric rotor or a defect in the motor(s).

Get in touch with Schulz

Authorized-Technical/

Distributor.

17. FAILURE DIAGNOSTICS

Loading...

Loading...