108

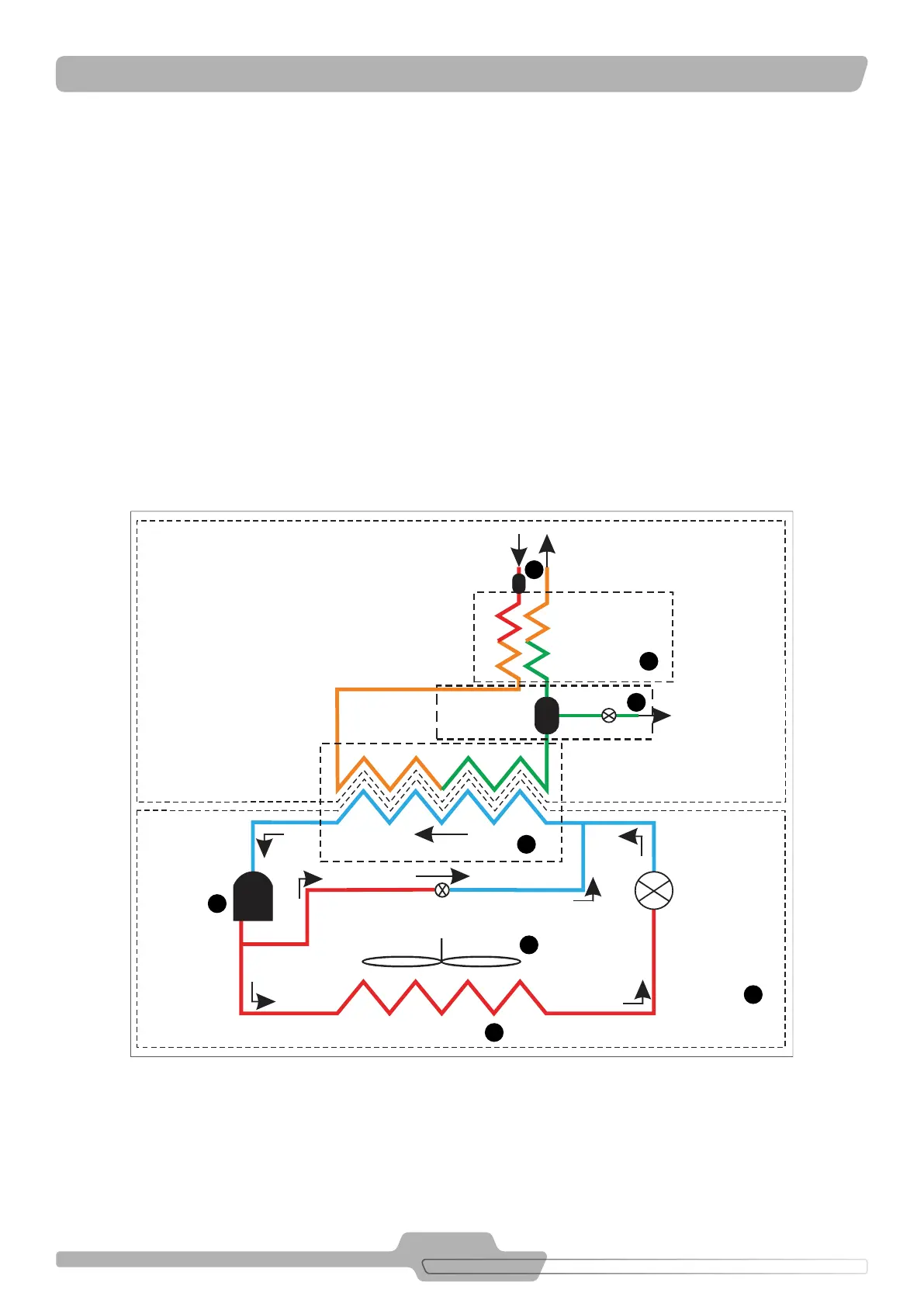

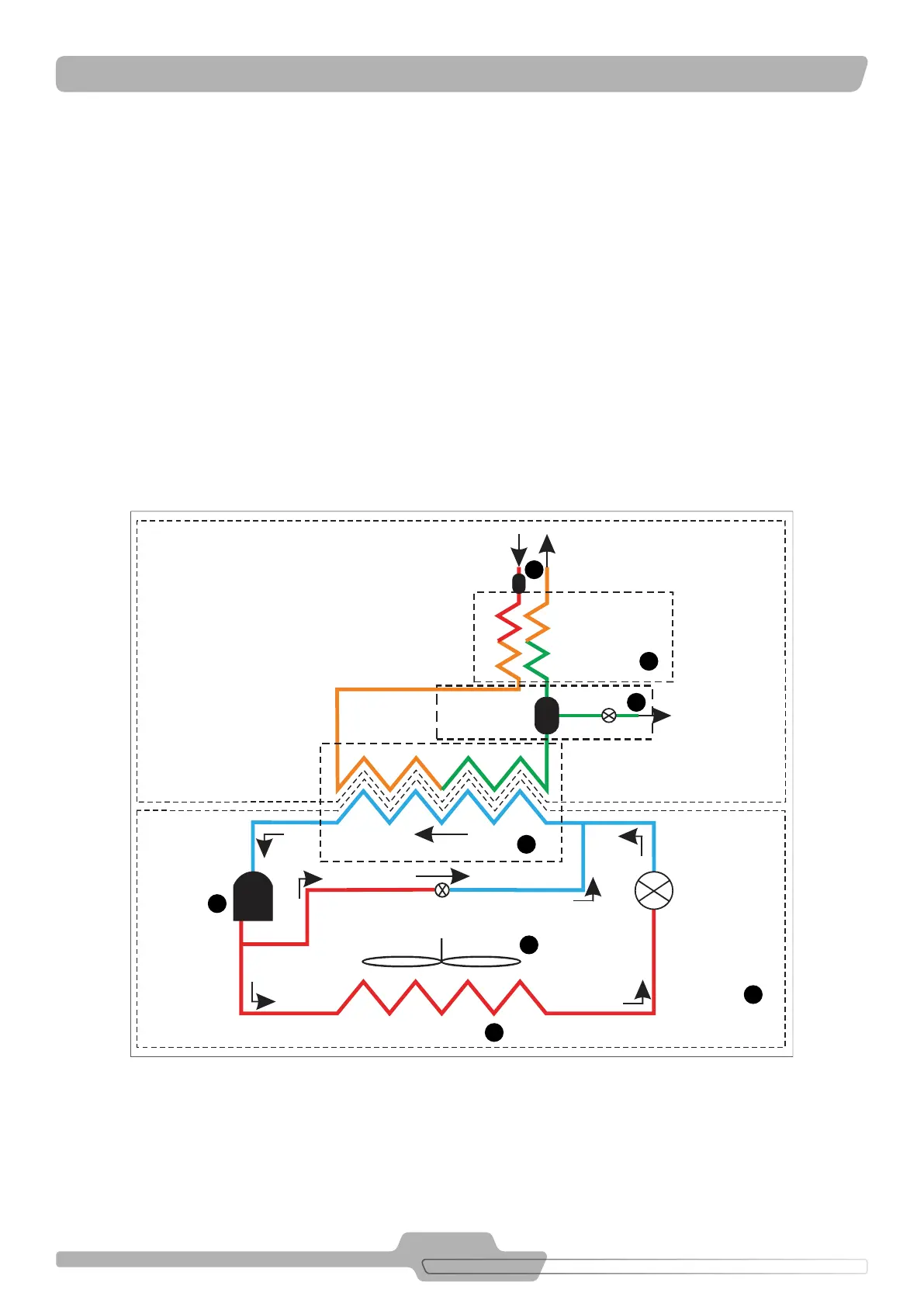

FIGURE 10.1 - REFRIGERATION AND PNEUMATIC CIRCUIT FOR SRS LINE - AIR DRYERS

1. SRS - Air Dryer

The SRS - Air Dryer operation removes the condensate and the humidity contained in the compressed air. The presence of water

in a liquid state in a compressed air network causes oxidation of the metallic components, as well as wear and tear on moving

parts, as the water washes the surfaces and removes lubricants. The water also harms pneumatic tools and any other industrial

process where quality is required in compressed air.

2. The machine operates as follows:

The SRS - Air Dryer removes humidity from the air by way of a refrigeration system. Humidity is removed through the cooling

of compressed air using a heat exchanger and the water is the by-product from this process. A temporized separator and drain

are used to conclude the process (1).

The compressed air process is done in two steps:

- First, a pre-cooling is done in the hear exchanger between the hot and humid air which enters and the dry and the discharged

cold air which leaves (2).

- The second step employs a refrigerant and damp air exchanger (3). The thermal exchange occurs until the temperature is

around the same as the refrigerant fluid. Due to the low temperature, the excess humidity present in the compressed air con-

denses. This happens as the dew point or water condensation temperature is reached. Within the heat exchanger the air is al-

ready dry and then reheated through thermal contact with the humid air and incoming air. This exchange allows for pre-cooling

the air which enters the dryer and slight warming of the compressed air. Now the air is dry and returns to the compressed air

consumption line.

The SRS - Air Dryer refrigeration system is equipped with a hermetic compressor (4), which draws the refrigerant fluid in the gaseous phase

from the evaporator (3), where a thermal exchange between the humid air and the refrigerant fluid occurs. The heat is absorbed from the

compressed air in the evaporator, condensed water vapor contained in the air. The refrigerant fluid is compressed when it passes through

the hermetic compressor, thereby raising the pressure and temperature. Following that, it flow enters the condenser (5), with a fan (6)

responsible for the air circulation cooling among the pipes and fins for cooling the refrigerant fluid. After the cooling phase, it flows through

the expansion device (7), located at the inlet of the evaporator to make the refrigerant fluid lower the pressure and temperature to restart

the cycle again.

PNEUMATIC CIRCUIT

REFRIGERATION CIRCUIT

Hermetic

Compressor

Outlet of dry

compressed air

Condensate

outlet

Condenser

Expansion device

(capillary tube or

thermostatic

valve)

Condensate

separator

Drain

Evaporator

Bypass system

Fan

Inlet of humid

Compressed air

pré-filtrer

Pre-exchanger

1

3

4

8

5

7

6

2

10. PRINCIPLE OF OPERATION

Loading...

Loading...