110

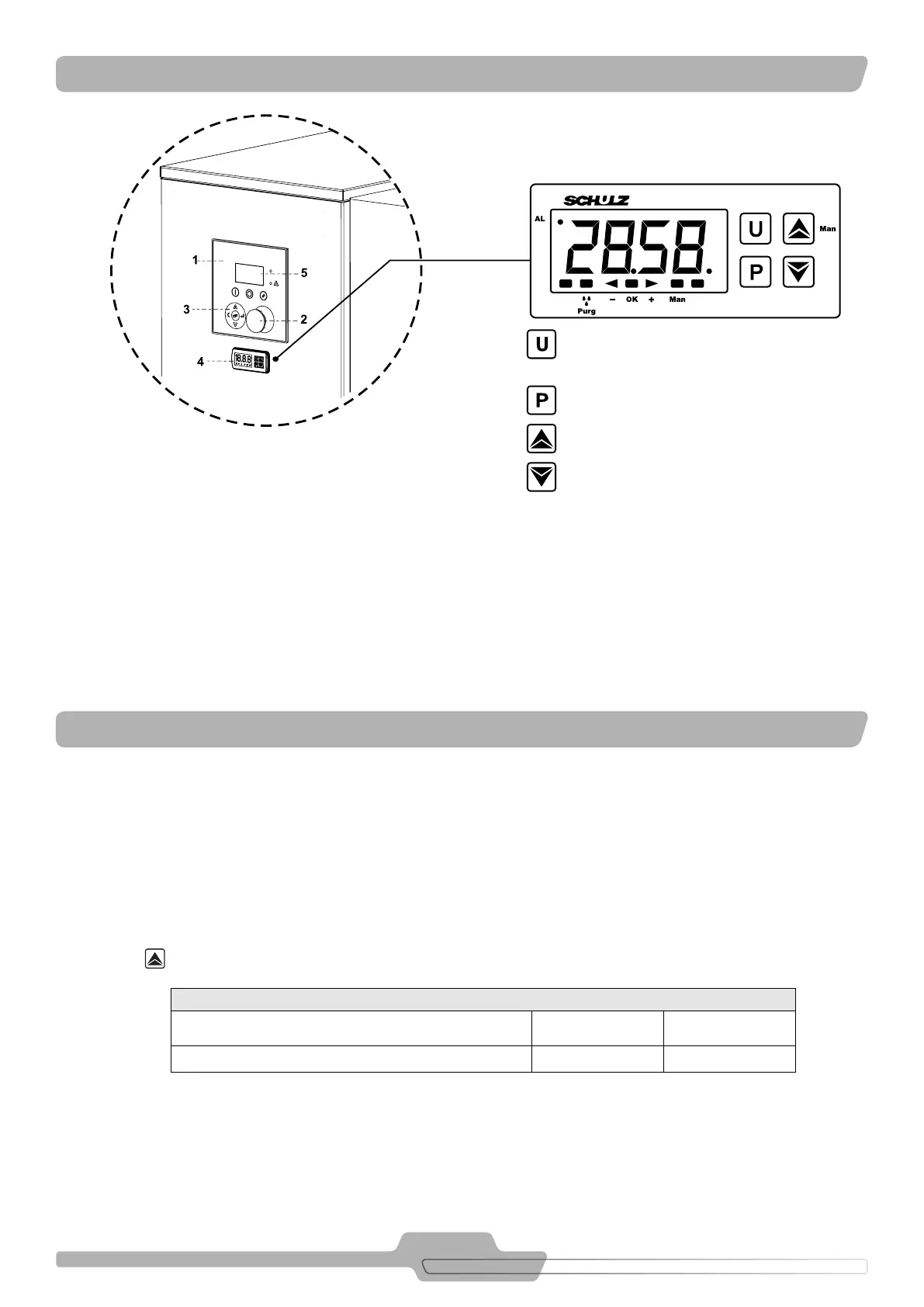

1. Electronic interface (Read the instructions in the manu-

al of the Electronic Interface)

2. Emergency stop button

3. Keys

4. Dryer electronic controller

5. Display

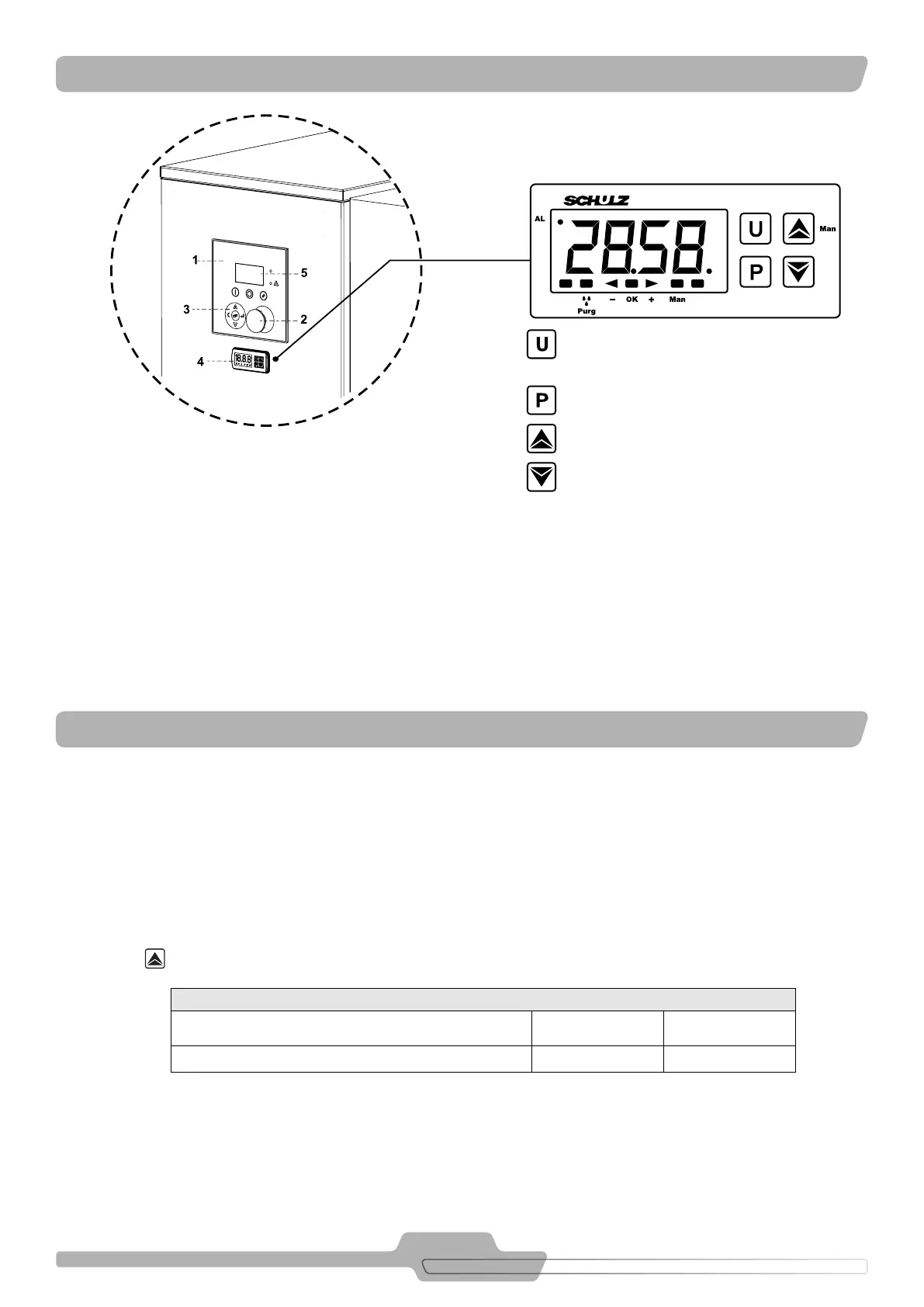

Verification of the Power Supply Voltage and

Temperature

Access to the parameters

Increase of test and drain parameters

Decrease

AL: to Temperature and/or voltage oscillation

Purg 3 little drops: to Activation of the drain

Man: to Manual drain activated

- : to Lower temperature limit reached (L0)

OK: to Normal operating conditions

+: to Upper temperature limit reached (HI)

. : to Access to the programming menus

FIGURE 11.1 - INSTRUMENT PANEL

FIGURE 11.2 - DRYER ELECTRONIC CONTROLLER

1. Introduction

The purpose of the Electronic Controller is to display the cooling temperature of the system to the operator, which is quite close to due point

temperature. A sensor is installed at the coldest place in the circuit to show the reading. Another purpose of the controller is to monitor the

activation time of the solenoid valve of the dryer drain and act as a safety device to turn off the equipment in case low temperatures to avoid

condensation freezing inside the heat exchanger.

2. Operating the Air Dryer

After turning on the Compressed Air Dryer, the Electronic Controller will display the version of this component for about 1 second. During

this time the temperature measured by the sensor will be displayed.

Based on the previously set time settings (see Table 12.1), the Electronic Controller will turn on the purge solenoid valve coil.

Press this key the dryer purge will be instantly activated or deactivated.

ISO 8573.1 - CLASSES QUALITY

Dry Model Intermittence Purge Time

SRS 20 to 1300 45 seconds 3 seconds

TABLE 12.1 – PURGE TIME

11. INSTRUMENT PANEL

12. ELECTRONIC CONTROLLER

Loading...

Loading...