87

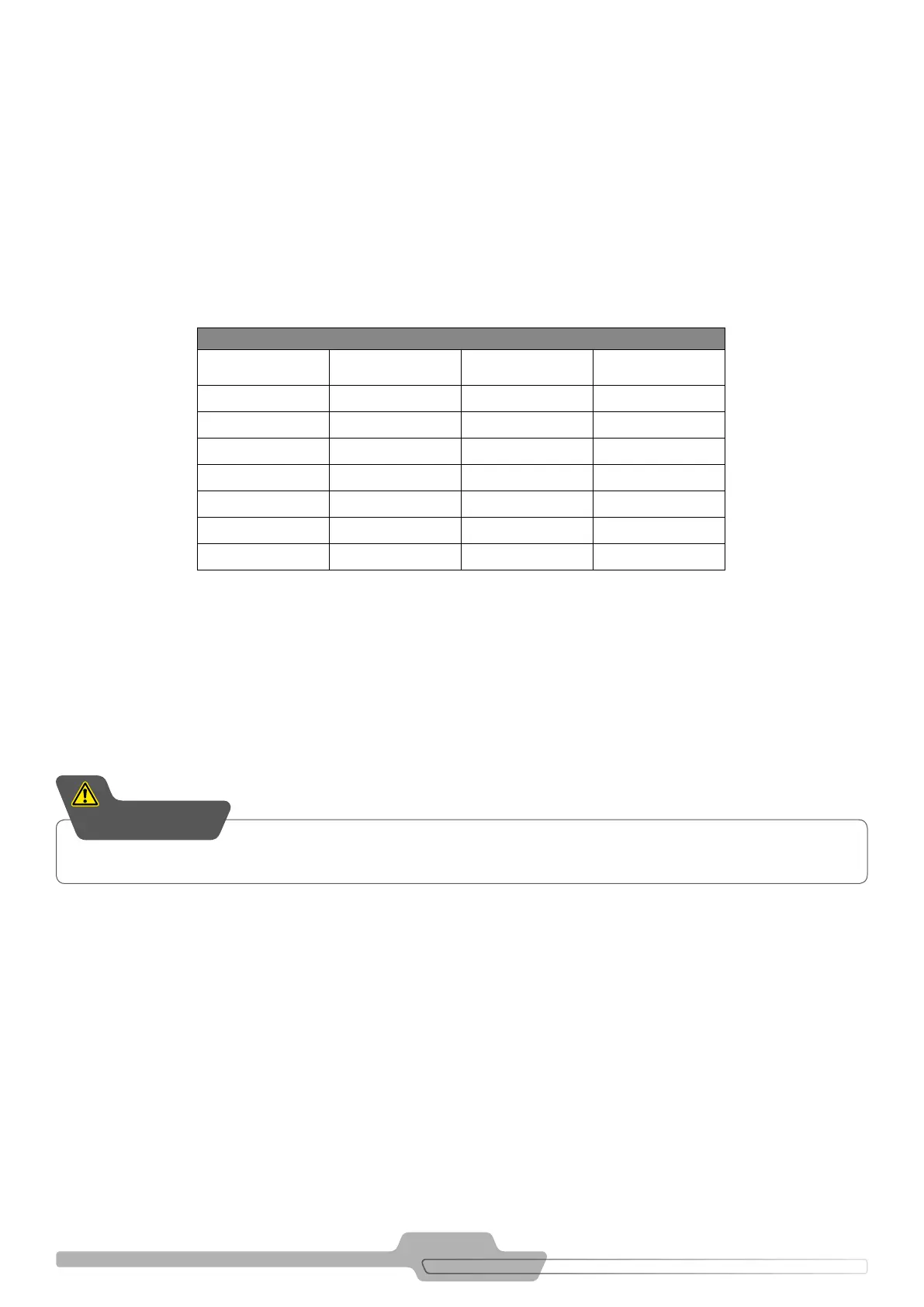

TABLE 9.1 – QUALITY CLASSES OF COMPRESSED AIR

ISO 8573.1 – QUALITY CLASSES

QUALITY

CLASSES

PARTICLE SIZE

IN MICRONS

WATER P.O.

°C E 7 barg

OIL INCLUDING

VAPOR mg/m³

1 0,1 -70 0,01

2 1 -40 0,1

3 5 -20 1,0

4 15 +3 5

5 40 +7 25

6 - +10 -

7 - - -

3. Foundation

The air dryer must be installed on a concrete base capable of supporting its weight and the forces resulting from its operation.

Install the SRS - Air Dryer by removing the base used for shipping and placing the rubber feet under it which were provided with the product.

Remove the EPS protection between the condenser unit fan and the hermetic compressor, before turning on the product. This is valid for

SRS models 170, 190 and 240.

4. Compressed air quality

The installation of a coalescent lter of 1µ (micron) is indispensable in the SRS - Air Dryer inlet for the purpose of avoi-

ding the entrance of oil and solid particles which may obstruct or harm the thermal exchange in the heat exchanger.

If the air processed by the dryer is supplied by an Alternating Piston Compressor a total pipeline course of at least 8 meters is recommended

between the reservoir and the dryer (or a coalescent pre-filter). This length of pipeline helps a great deal in cooling the compressed air before

going into the dryer.

It depends on the quality of the compressed air to evaluate the need of installing one or more filters. The purpose is to avoid the accumulation

of particles in the line. It is recommended to install coalescent filters to comply with the ISO 8573 Standard (Illustration 9.1).

In short pipelines, it is always convenient to install a reservoir with at least 1/5 of the compressed air volume produced by the compressor

(measure the flow in liters/minute for the installed compressor). It is strongly recommended to install the reservoir before the Air Dryer

to avoid flooding the dryer from the condensed water coming from the air compressor, which can overload the operating capacity of the

equipment.

In a good compressed air network project, it requires the installation of a reservoir/condensate separator to absorb the pulsations generated

through sudden consumption and strategically maintain a reserve supply to protect against consumption peaks.

We recommend installing in the compressor outlet or in the compressed air line, a derivation with a hose and spray nozzle for cleaning the

condenser and other maintenance jobs required as the need arises at the compressed air installation site.

It is recommended to place the compressed air equipment in such a way so the hot air outlet from cooling

the compressed air is not pointed towards the reservoir or condenser separator as to not compromise the

quality of the compressed air (Illustration 9.1)

IMPORTANT

Loading...

Loading...