30 User Manual 54Base

6.2 Preventive maintenance

Our machines are designed in such way that they need little (preventive) maintenance in addition

to the cleaning.

The following checks have to be performed:

• Auto-grip shafts with blocking cords.

6.2.1 Auto-grip shafts

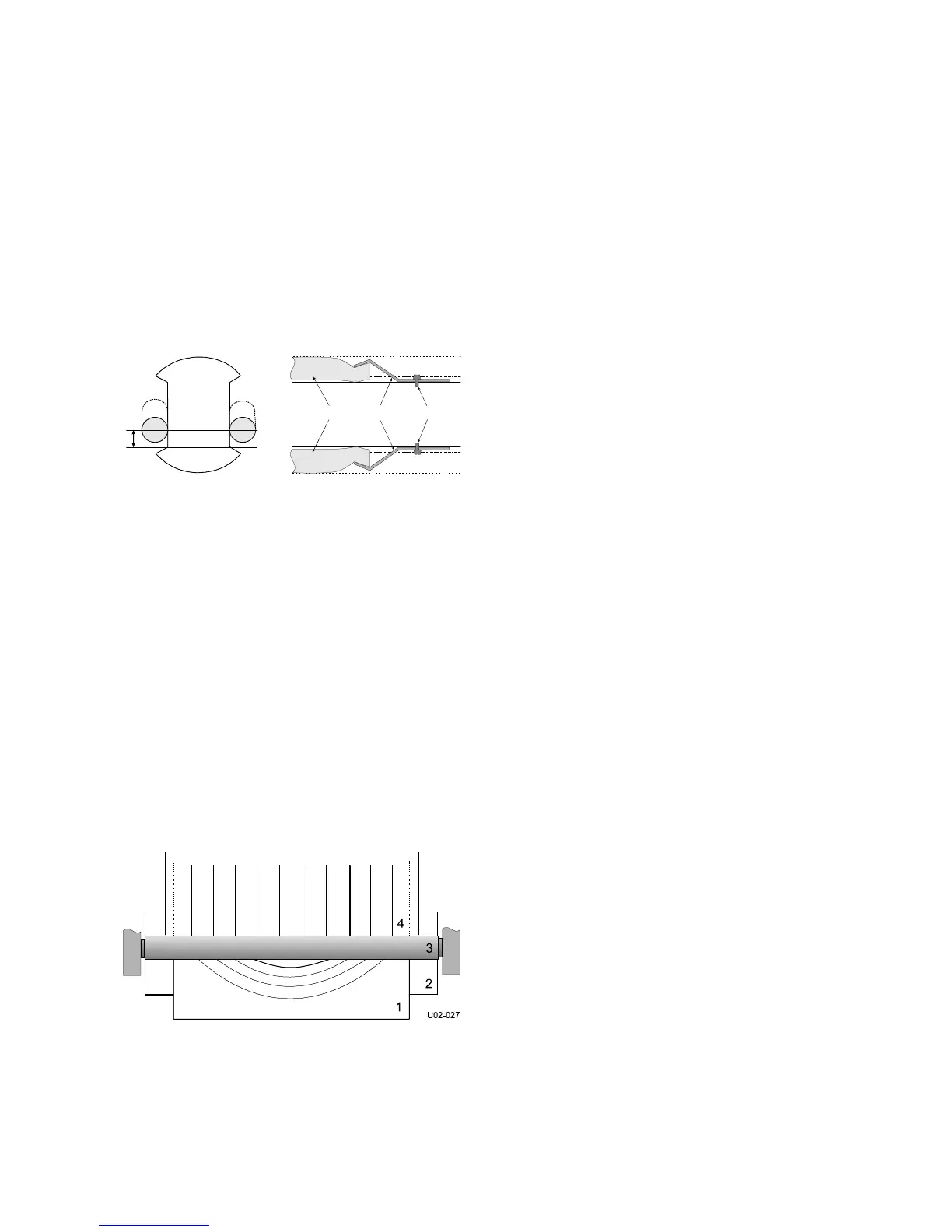

Check the auto-grip mechanism on each shaft.

• The distance (d) between the rubber cords and the edges of the recess should be 8 ± 2.5 mm

minimum (the cord must not touch the skew).

Figure 18: Auto-grip shaft

If not, correct as follows:

• Loosen the clamp (2) with the screw (1) until the cord is free on one side,

• Shorten the cord by approximately 10 mm (0.4 in.),

• Put the end of the cord back underneath the clamp (2),

• Secure it by tightening the screw (1).

6.3 Trouble shooting

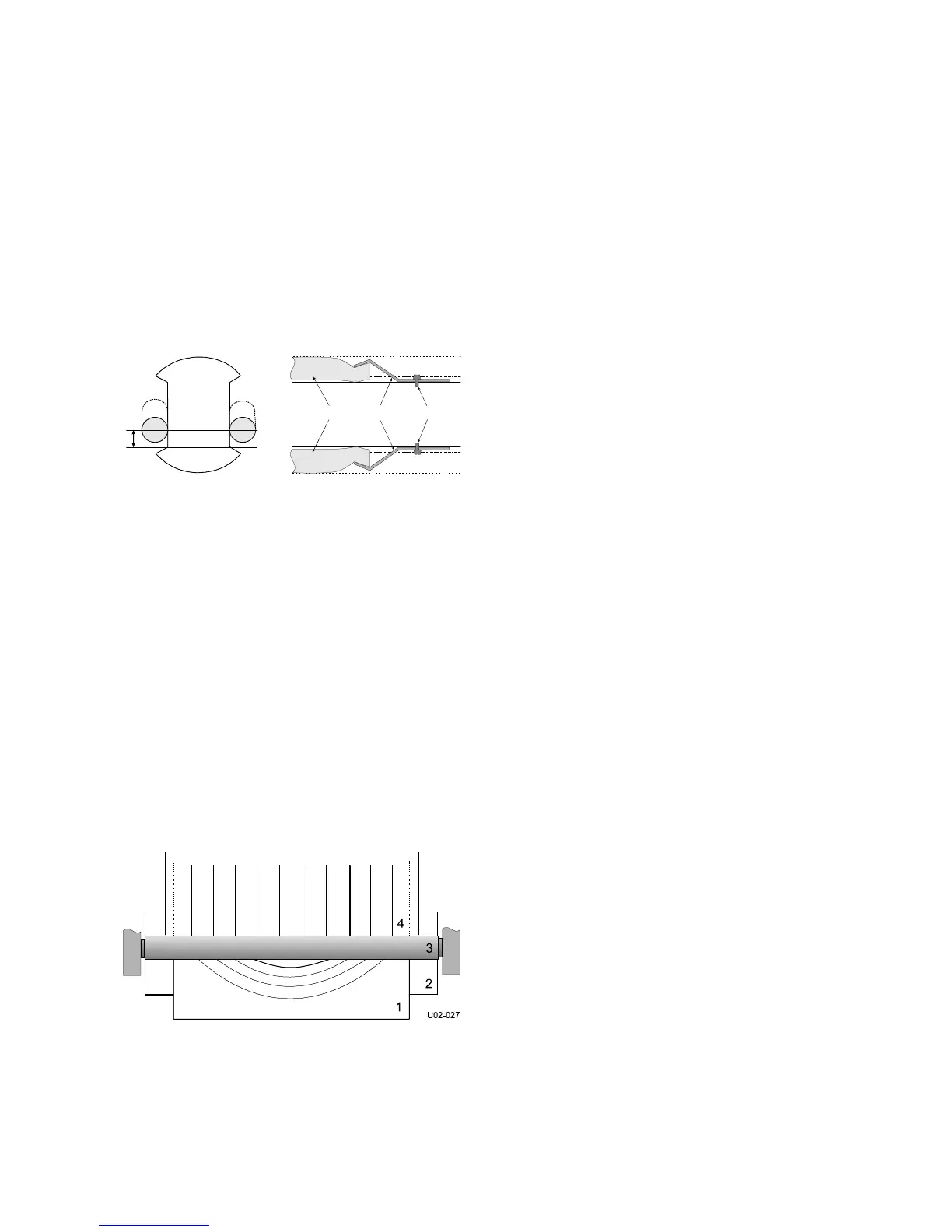

During processing wrinkles can show up in the image (1) on the in-feed table (2) and in the

process result (4) on the output table.

The figures below show some examples where it is caused by the main rollers (3) and gives a

possible solution.

Wait until a few meters is processed to see results.

Pressure too high.

Figure 19: Wrinkles due to high pressure.

• Decrease the roller pressure a little (5-10%).

d

123

Loading...

Loading...