2.3 Process principle

In all processes the materials are fed through the nip from the front side to be joined together by

pressure.

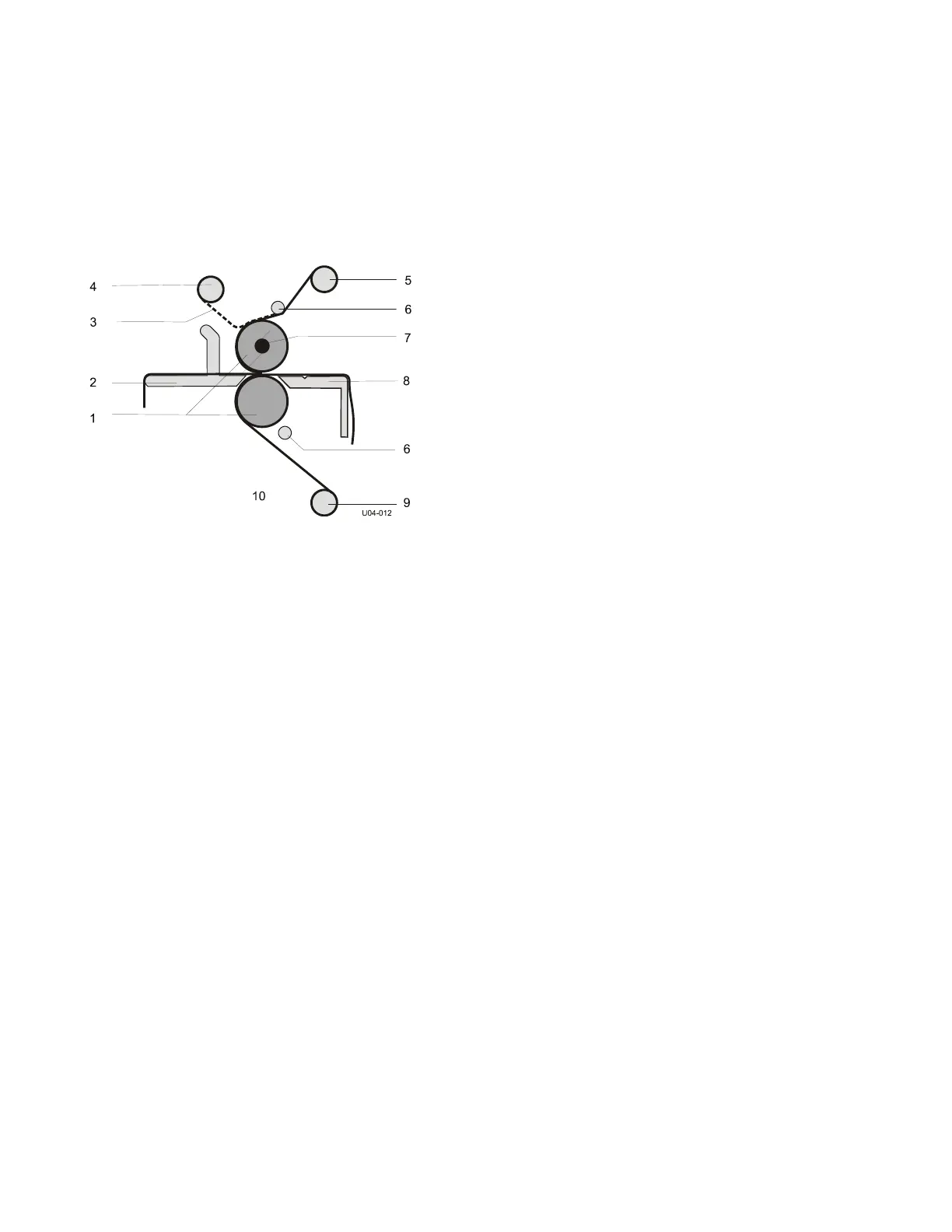

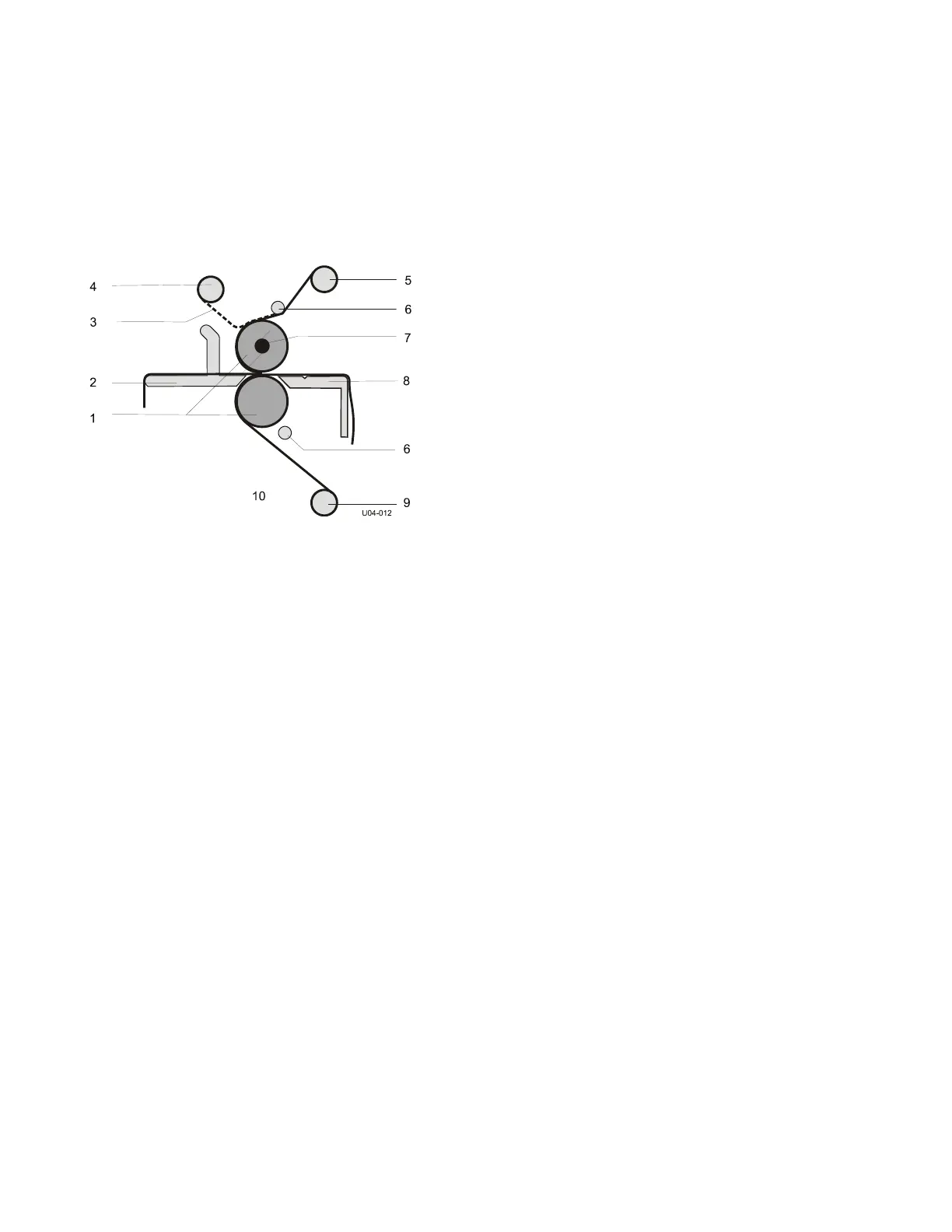

A process that makes maximum use of the machine is shown in Figure 3. Shown is a double sided

laminating (decalling) process.

The top coating film is a pressure sensitive film with release liner (3) taken from a supply roll on the

(rear) upper unwind shaft (5). The bottom coating film is a pressure sensitive (mounting) film without

release liner taken from a supply roll on the lower unwind shaft (9).

Figure 3: Creating Pop-up art, including image supply from roll.

The image that has to be coated on both sides is fed between the main rollers (1) via the in-feed

table (2).

When using a pressure sensitive laminate, it often has a release liner (3) that has to be removed. As

in the top half, it runs via a splitter bar (6) where the release liner is removed. This release liner is

rolled up onto the wind-up shaft (4) in the upper section.

When using a pressure sensitive laminate without a release liner (like in the bottom section), it must

not run via the splitter bar to avoid the film sticking to the bar and leaving adhesive residue behind.

A mounting film has adhesive on both sides and release liner on just one side. This release liner has

to stay on until the image is mounted. So a mounting film is processed in the bottom section the

same way as a laminate without release liner.

The upper main roller can be heated (7) to a fixed temperature of 40C. This is called ‘heat assist’

and can be used to activate the adhesive to flow more evenly and get a better bonding between

laminate and image.

Loading...

Loading...