8

SeaStar Hydraulic Jackplate

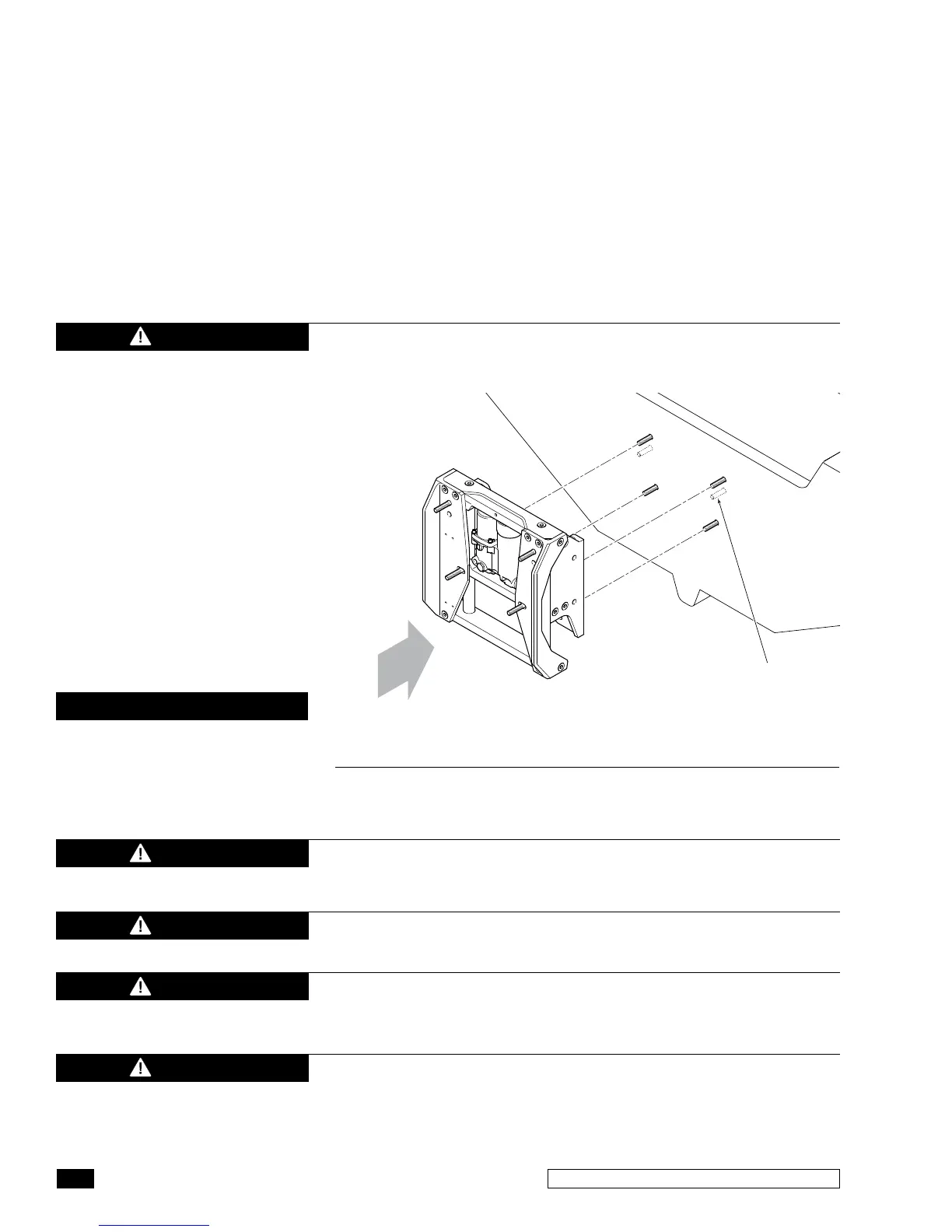

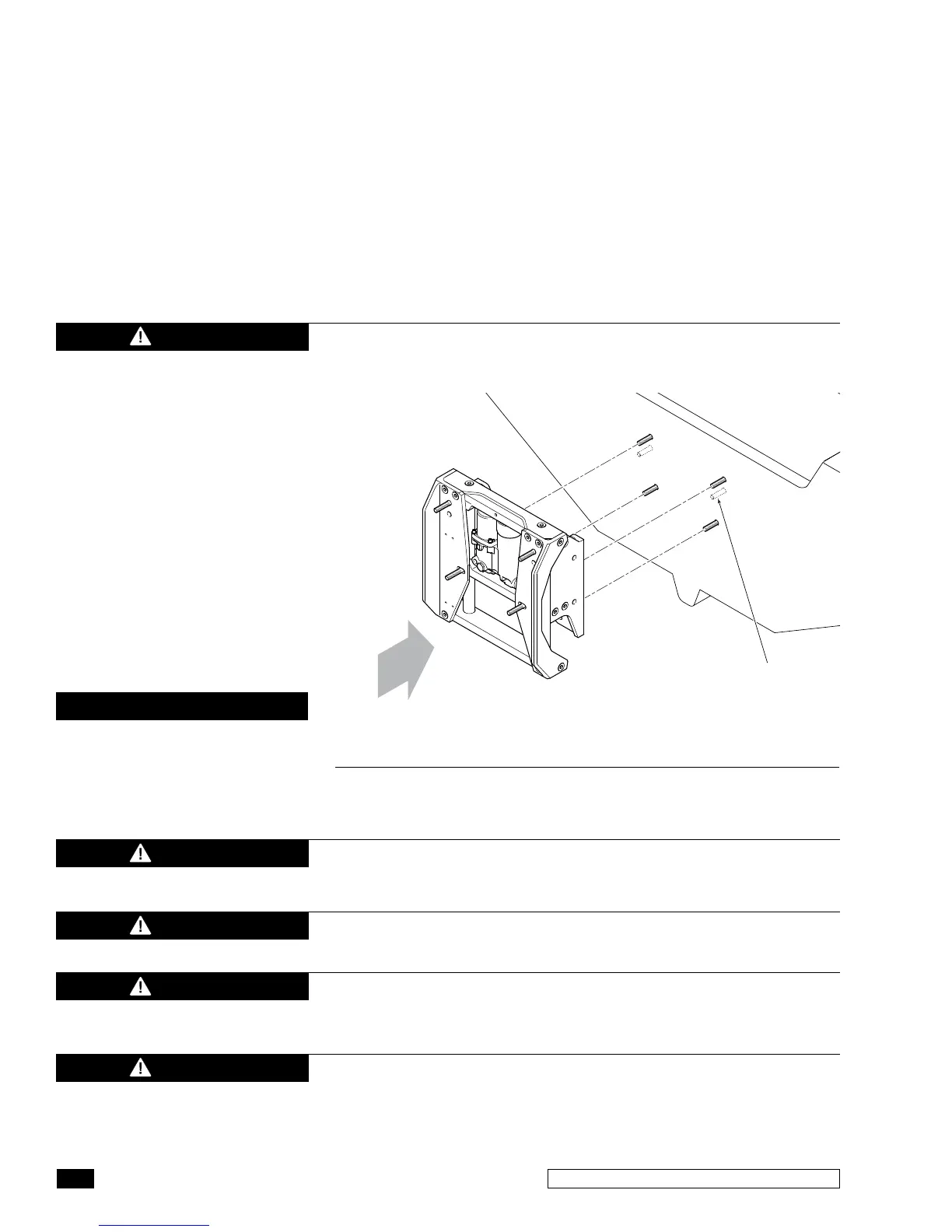

ADDITIONAL BOLTS

RECOMMENDED IN CASE

OF 10" OR 12" SETBACK

OR 250

+

HP ENGINE

3. If the Jackplate setback is 10 inches or more, or if the outboard

engine output is 250 horsepower or more, it is recommended to

use

6 mounting bolts at the transom connection. Additional

mounting

bolts should be used in the upper holes on the Jackplate

hole pattern. See figure 8.

4. Seal all holes in the transom with an appropriate marine sealant.

1/2" x 1-1/16" OD SAE must be used with the engine mounting

bolts to ensure proper clearance and bolt preload.

Figure 6. Jackplate to transom connection.

WARNING

CRUSH HAZARD. Moving Jackplate parts can crush. Keep all body

parts free and clear when actuating the Jackplate.

WARNING

The use of 6 mounting bolts is recommended for installations of

10” or 12” setbacks or for outboard engines with output greater

than 250 horsepower.

WARNING

Follow the outboard engine manufacturer’s recommendations for

tightening torque.

WARNING

Use of non-approved bolts and washers may lead to separation of

engine from boat.

WARNING

At the lowest position, the Jackplate

provides a 2-1/2" lift offset between

the transom and the engine.

NOTICE

Loading...

Loading...