11

4.1

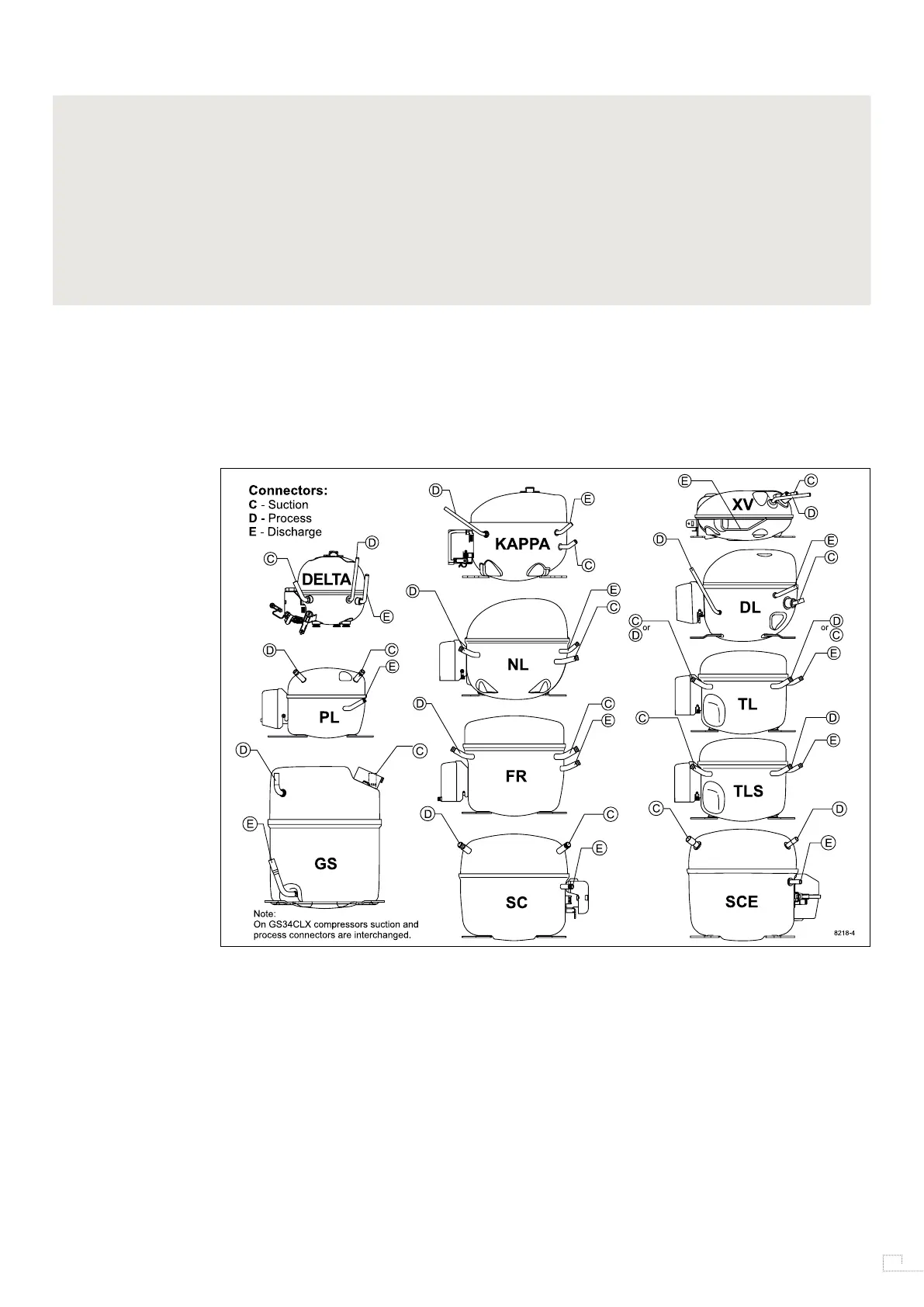

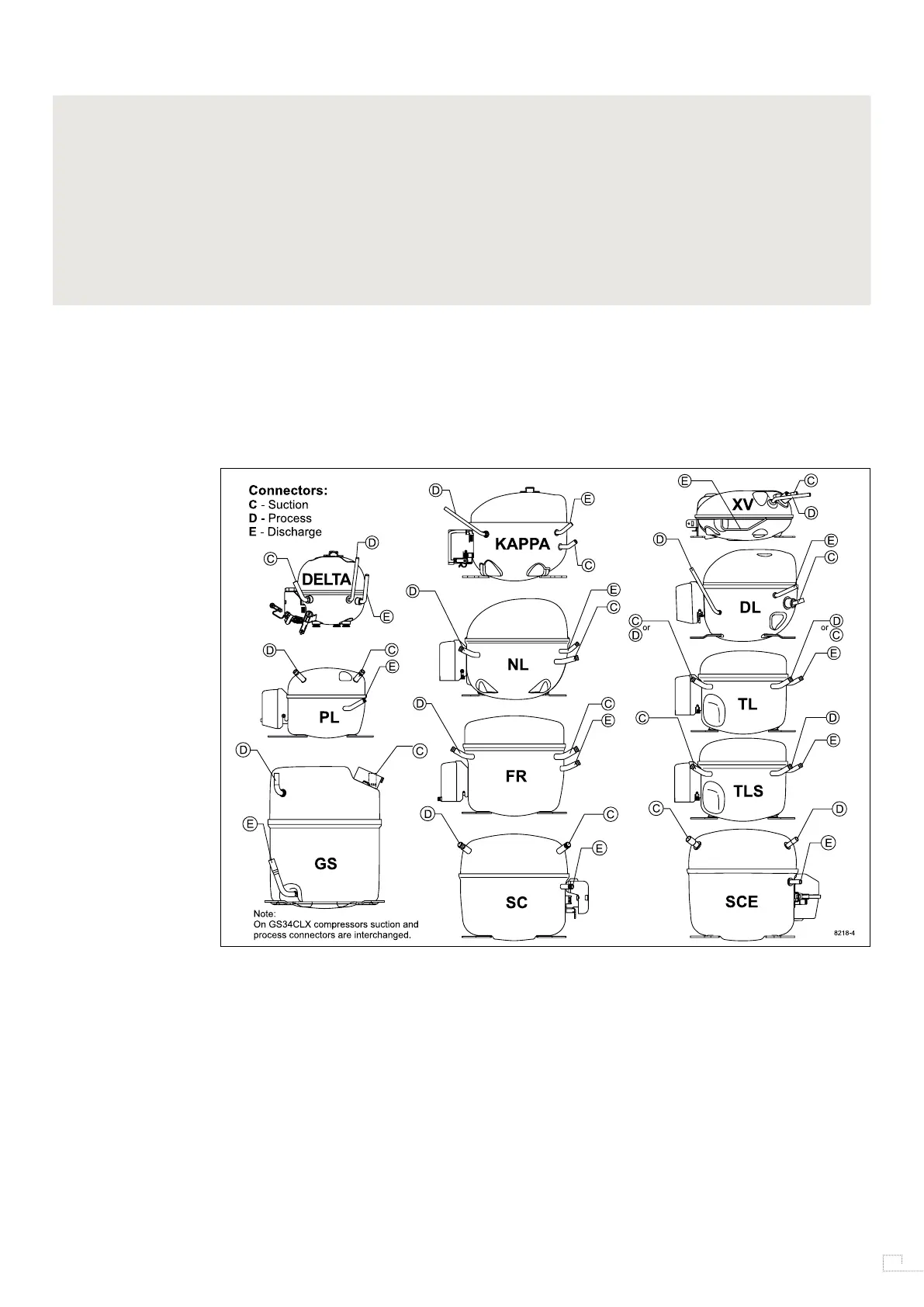

Connectors

4.

MOUNTING

Brazing problems caused by oil in the connectors can be avoided by placing the compressor on its base plate

some time before brazing it into the system. The compressor must never be placed upside down.

The system should be closed within 15 minutes to avoid moisture and dirt penetration.

The positions of connectors are found in the sketches. “C” means suction and must always be connected to

the suction line. “E” means discharge and must be connected to the discharge line. “D” means process and

is used for processing the system.

Most compressors are supplied with sealed connectors, which consist of a thick-walled copper plated steel

tube with great corrosion resistance and good braze ability. The connectors are welded in the compressor

housing and thus the weld cannot be destroyed by overheating during brazing operations. The seal is an

aluminum cap which gives a tight seal. Compressor with copper connectors are sealed with rubber plugs.

The aluminum cap sealing ("capsolut") offers a tight seali. The seal ensures that the compressors have not

been opened after leaving Secop´s production lines. In addition to that, the seal makes a protecting charge

of nitrogen superfluous.

220 V compressors are normally supplied with millimeter tubes, while 115 V compressors are supplied with

inch tubes. All connectors have a shoulder to provide optimal brazing conditions. Expanding the connectors

by more than 0.3 mm / 0.01 inch in is not allowed.

Compressors with an “S” in the model denomination and all NL/DL/SCE types have a direct intake system,

which means increased capacity. The suction connectors at these compressors must be connected to the

suction line to prevent capacity loss.

For the refrigerants R600a and R290, process tubes can be closed with a LOKRING® connection.

Brazing is not allowed on systems with flammable refrigerants.

Loading...

Loading...