8

1.5

Low and high starting

torque

1.6

Motor protector and

winding temperature

1.7

Rubber grommets

1.8

Minimum ambient

temperature

1.9

SC Twin compressors

Description of the different electrical equipment shown can be found in the data sheets for the compressors.

See also chapter 4. Low starting torque (LST) compressors must only be used in refrigerating systems with

a capillary tube throttling device where pressure equalization is obtained between suction and discharge sides

during each idle period.

A PTC starting device (LST) requires that the idle time is at least 5 minutes, since this is the time necessary

for cooling the PTC.

The HST starting device, which gives the compressor a high starting torque, must always be used in refrig-

eration systems with an expansion valve, and for capillary tube systems without full pressure equalization

before each start. High stating torque (HST) compressors are normally using a relay and starting capacitor

as starting device.

The starting capacitors are designed for short time cut-in.“1.7 % ED”, which is printed on the starting ca-

pacitor. This means for instance max. 10 cut-ins per hour each with a duration of 6 seconds.

Most of the Secop compressors are equipped with a built-in motor protector (winding protector) in the motor

windings. See also chapter 2.1. At peak load, the winding temperature must not exceed 135 °C / 275 °F and

nderstable conditions, the winding temperature must not exceed 125 °C / 257 °F.

Refer to our data sheets for specific information.

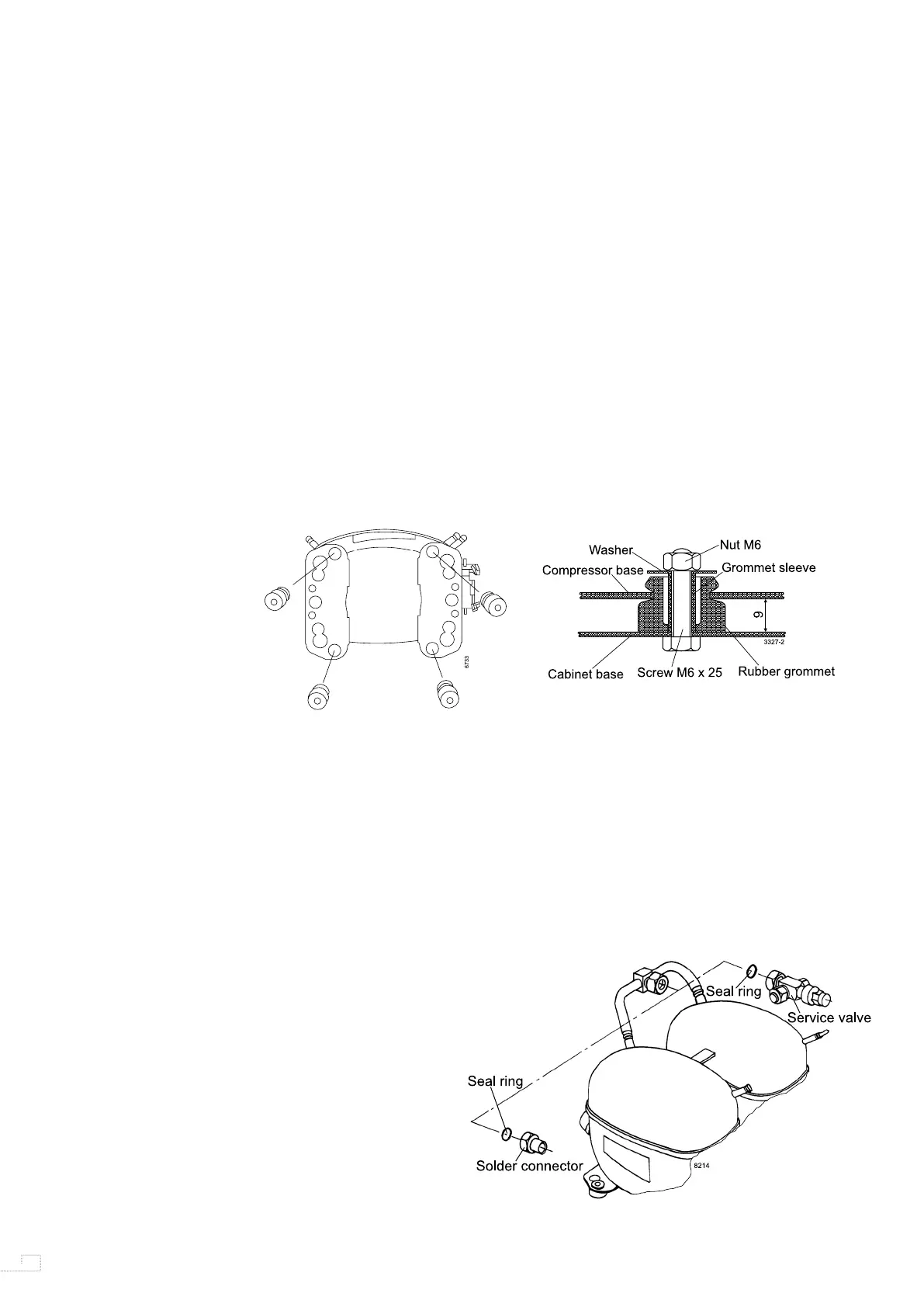

Stand the compressor on the base plate until it is fitted. This reduces the risk of oil coatings inside the con-

nectors and associated brazing problems. Place the compressor on its side with the connectors pointing

upwards and then fit the rubber grommets and grommet sleeves on the base plate of the compressor. Do

not turn the compressor upside down. Mount the compressor on the baseplate of the appliance

Tightening torque for M6 bolt joint mountings should be 5 Nm ± 0,5 / 44 in-lb ± 4,4 (hand-tight).

Allow the compressor to reach a temperature above 10 °C / 50 °F before starting for the first time to avoid

starting problems.

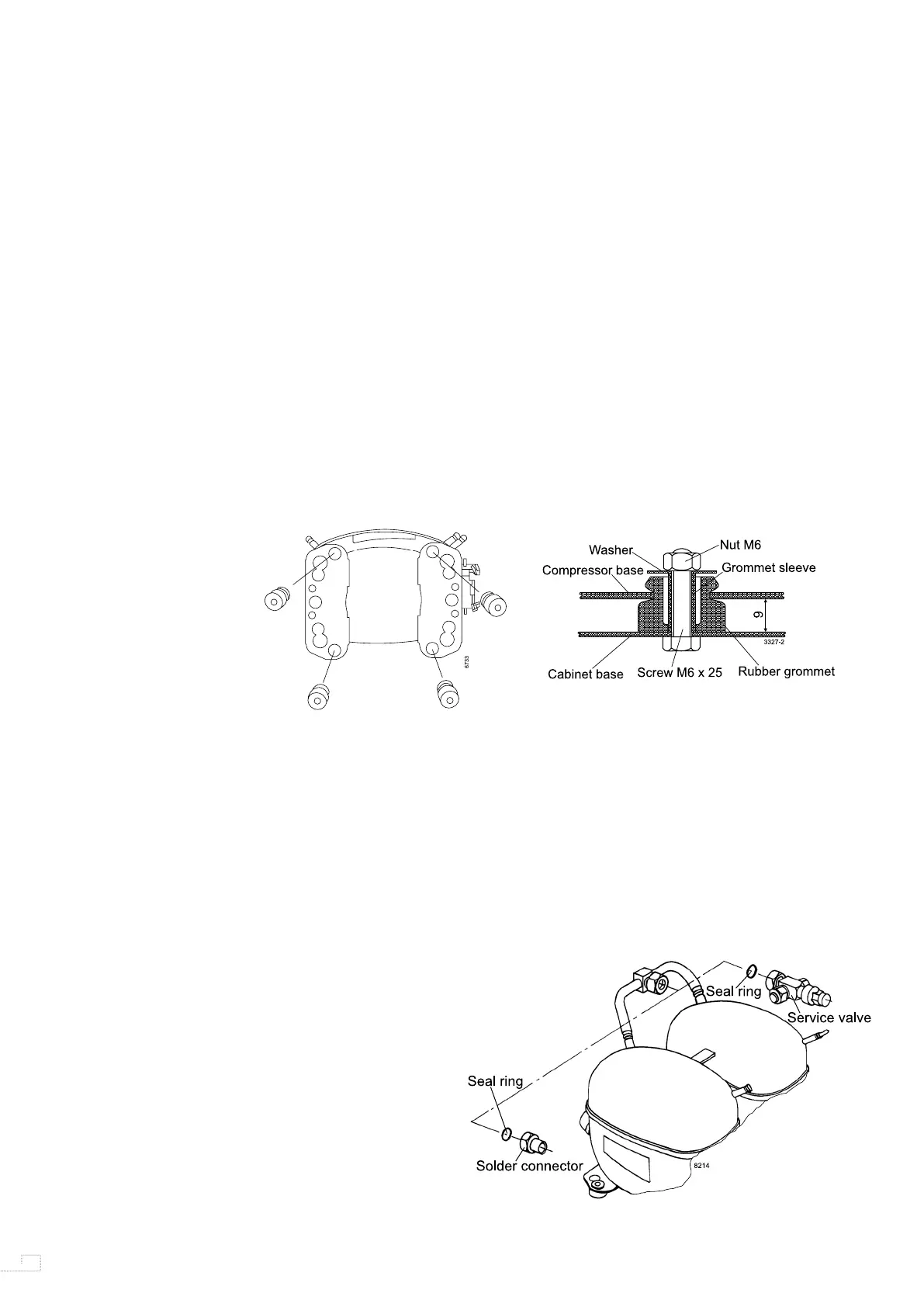

The twin version consists of two SC compressors mounted on a common base plate. The two compressors

are joined by an oil-equalizing tube and also have an intake manifold with screw connector for a service valve

or a braze connector (these parts are supplied as accessories, please refer to data sheets for more info).

Each twin compressor is supplied with two sets of electrical equipment and mounting accessories.

Loading...

Loading...