12

4.2

Expanding connectors

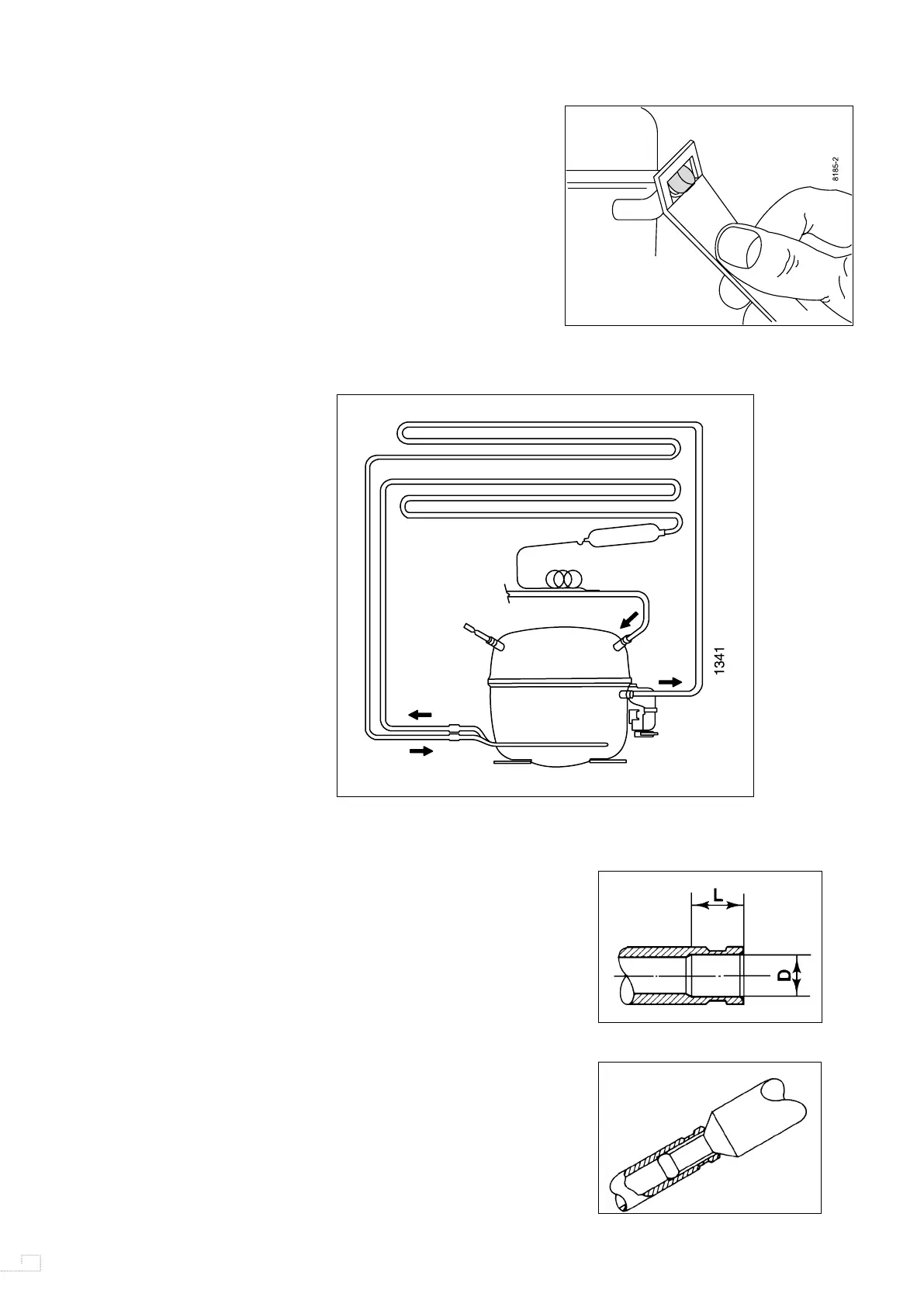

The "capsoluts" are easily removed with an ordinary pair of pliers or a special tool as shown. The "capsolut"

cannot be remounted.

When the seals on the compressor connectors are

removed, the compressor must be mounted in the

system within 15 minutes to avoid moisture and dirt

penetration.

"Capsolut" seals on connectors must never be left in

the assembled system.

Oil coolers, if mounted (compressors from 7 cm

3

displacement), are made of copper tube and the tube con-

nectors are sealed with rubber plugs. An oil-cooling coil must be connected in the middle of the condenser

circuit.

SC Twin compressors must have a non-return valve in the discharge line to compressor no. 2. If a change

in the starting sequence between compressor no.1 and no. 2 is desired, a non-return valve must be placed

in both discharge lines.

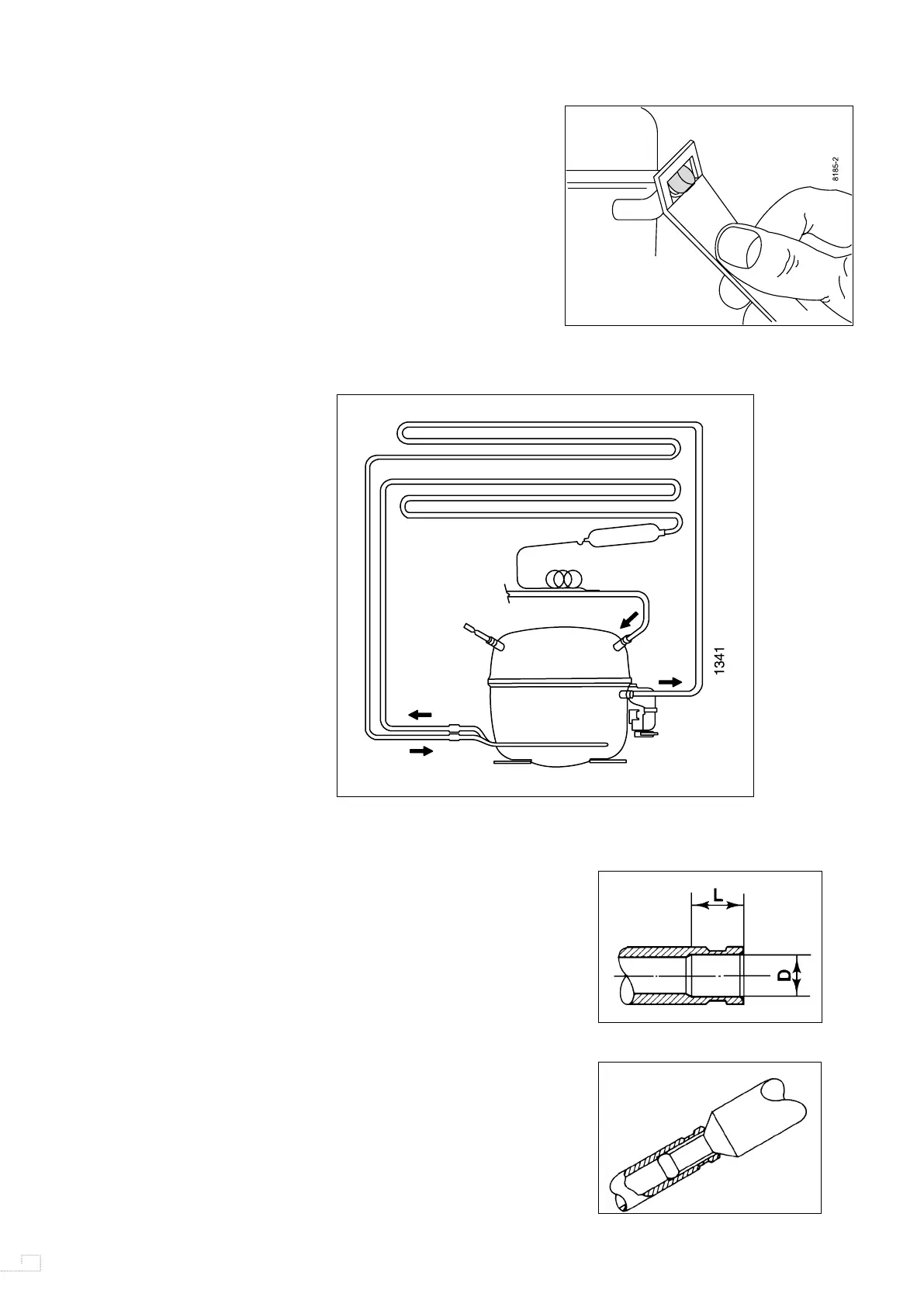

In order to create optimum conditions for braz-

ing and to minimize the consumption of filler

metal, all tube connectors on Secop compres-

sors have shoulders, as shown

It is possible to expand the connectors with in-

side diameters f 6.2 mm to 6.5 mm which suit

1⁄4” (6.35 mm) tubes, but we advise against ex-

panding the connectors by more than 0.3 mm

(0.01 inch). When expanding, it is necessary to

have a suitable counterforce on the connectors

so that they don’t break off.

A different solution to this problem would be to

reduce the diameter of the end of the connector

tube with special pliers.

Loading...

Loading...