18

Prior to assembly, the pipe ends have to be cleaned thoroughly with fine steel wool or abrasive sheets, using

a rotating motion. Ths prevents scratches along the pipes, which could lead to an insufficent seal.

To ensure a sealed connection, the pipe ends are treated with LOKPREP®. This evens out any irregularities

on the pipe’s surface and quickly hardens. After the insertion of the pipe end into the connection pieces,

the pipes should be rotated by 360°, to guarantee the sealant spreads evenly. Afterwards, the two rings are

compressed to the stop in the middle with a special pair of pliers for manual assembly.

Depending on the material and the environmental temperature, the LOKPREP® hardens in three to four

minutes, so that all necessary connections can be established alongside the replacement of the compressor

and filter dryer as well as the filling process. Due to maximal precision in the manufacturing process, the

connection can be established with minimal effort. It guarantees an absolutely clean, inseparable and purely

mechanical pipe connection with high durability regarding the hermetical seal.

Servicing and repair for R600a and R290 systems is possible for skilled and well trained service technicians.

Our video "Compressor Service for Isobutane (R600a) and Propane (R290) – Step by Step" can be used as a

reference (https://www.secop.com/solutions/compressor-qa-tools/compressor-service/)

Local laws and regulations must also be taken into account. Very careful handling is required due to the

flammability of the gas, which is a potential danger during work on the refrigeration system.

The disposal of R290 and R600a does not include the filling of a recycling cartridge. Due to the low GWP, the

flammable refrigerants are directed away from the workplace into the open through a tube. External ignition

sources must be avoided During the process.

Good ventilation of the room is necessary and the discharge of the vacuum pump must be lead to open air.

The equipment of the service technician must meet the requirements of R600a and R290 in terms of evacu-

ation quality and refrigerant charge accuracy. An electronic scale is recommended to control refrigerant

charge to within the needed accuracy.

The maximal filling capacity is 150 g / 5.3 oz. per system, which equates to approximately 8 g/m³ in a 20 m³

kitchen and thereby around 25 % of the lower flammability limit. These precautions minimize the risk of an

ignition in case of a leakage. Exceeding these values is officially allowed under favorable conditions.

All manufacturers of HC-systems have to follow these safety regulations. The customer service, as well as

the repair of R600a and R290 applications, should only be accomplished by highly trained and experienced

personnel.

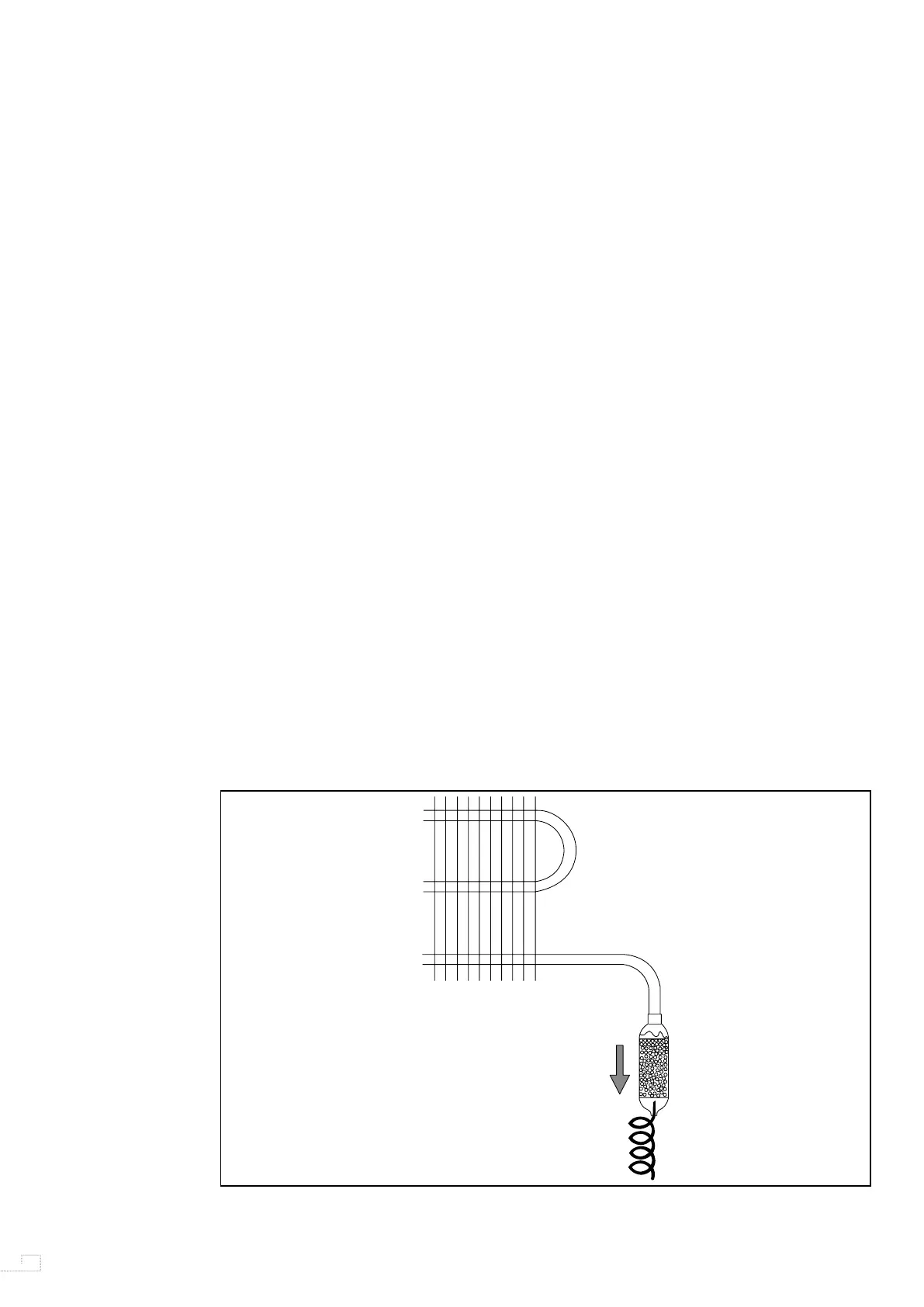

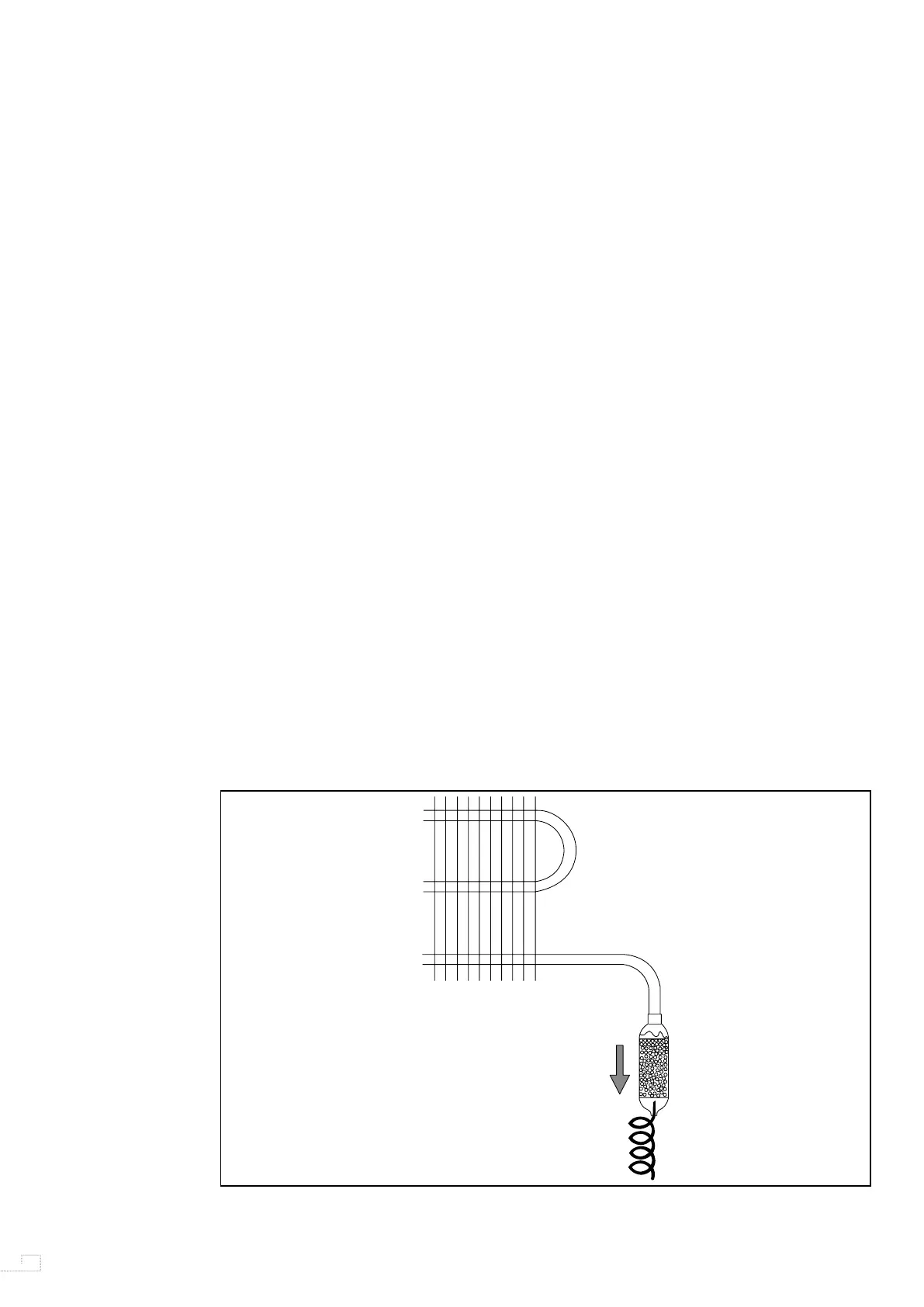

Secop compressors are expected to be used in well dimensioned refrigerant systems including a drier con-

taining an adequate amount and type of desiccant and with a suitable quality.

The refrigerating systems are expected to have a dryness corresponding to 10 ppm. As a max limit 20 ppm

is accepted.

The drier must be placed in a way ensuring that the direction of flow of the refrigerant follows gravitation.

Thus the MS beads are prevented from moving among themselves and therefore creating dust and possible

blockage at the inlet of the capillary tube. For capillary tube systems this also ensures a minimal pressure

equalizing time.

Pencil driers should be especially chosen carefully to ensure proper quality. In transportable systems only

driers approved for mobile application are to be used.

A new drier must always be installed when a refrigeration system has been opened.

7469

4.10

Driers

Loading...

Loading...