54

30.

EVACUATION

After brazing, evacuation of the refrigeration system begins. When a vacuum below 1 mbar is achieved, the

system is pressure equalized before the final evacuation and charging of refrigerant. If a pressure test has

been performed directly before evacuation, the evacuation process is to be started smoothly, with low pump-

ing volume, to avoid oil loss from the compressor. Many opinions exist on how evacuation can be carried out

in the best way. Depending on the volume conditions of the suction and the discharge side in the refrigera-

tion system, it might be necessary to choose one of the following procedures for evacuation.

One-sided evacuation with continuous evacuation until a sufficiently low pressure in the condenser has been

obtained. One or more short evacuation cycles with pressure equalization in between is necessary.

Two-sided evacuation with continuous evacuation until a sufficiently low pressure has been acvhieved.

These procedures naturally require a good uniform quality (dryness) of the components used.

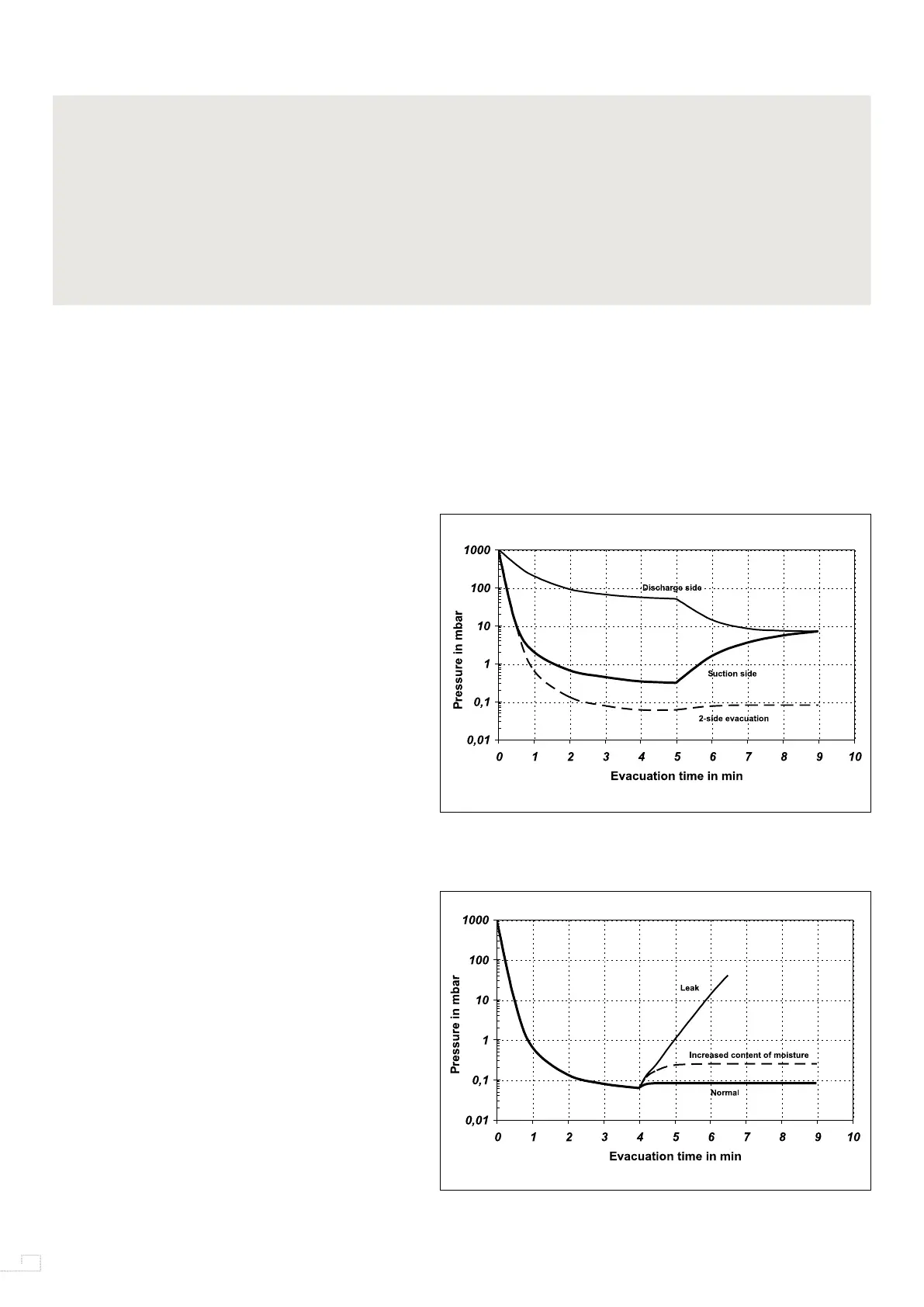

The first figure shows a typical

course of a one-sided evacuation

from the process tube of the com-

pressor. It also shows a pressure

difference measured in the con-

denser. This can be remedied by

increasing the numbers of pres-

sure equalizations. The dotted

line shows a procedure where two

sides are evacuated simultane-

ously.

If time is limited, the final vacuum

to be obtained is only dependent

on the capacity of the vacuum

pump and the content of non con-

densable elements or refrigerant

residues in the oil charge.

The advantage of a two-sided

evacuation is that it is possible to obtain a considerably lower pressure in the system within a reasonable

process time. This implies that it will be possible to build a leak check into the process in order to sort out

leaks before charging the refrigerant.

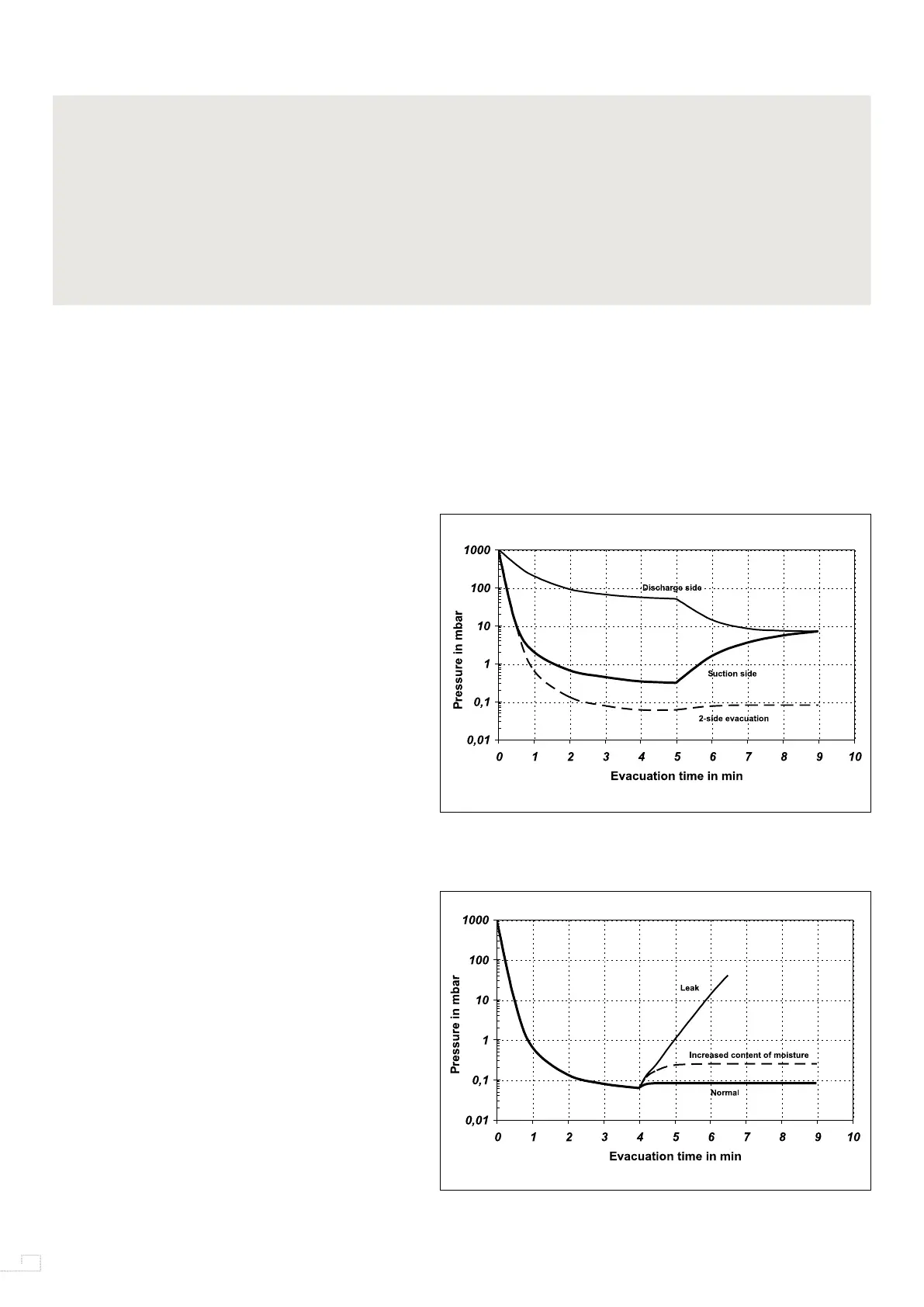

The second figure is an example

of a pre-evacuation process with

built-in leak test. The level of

vacuum obtained depends on the

process chosen. Two-sided evacu-

ation is recommended.

An explosion safe vacuum pump must be used for systems with the flammable refrigerants R600a and R290.

The same vacuum pump can be used for all refrigerants if it is charged with Ester oil.

30.1

Vacuum pumps

Loading...

Loading...