508.366.1488 | www.semshred.com

8. Service Instructions

PROCEDURE - BELTS

Prior to startup of this machine it is recommended that the drive belt tension is checked for proper run in deflection force as

shown in illustration. After the equipment has run between 24 and 48 hours, drive belt tension must again be checked

for proper operational deflection. A V-belt drive will successfully transmit its rated capacity if the belts are properly

tensioned. To tension:

1. Verify that the alignment of the pulleys is correct. Utilizing a straight

edge of sufficient length to span from one pulley to the other,

place it along the sides of both pulleys. The entire edge of each

pulley should fully contact the straightedge.

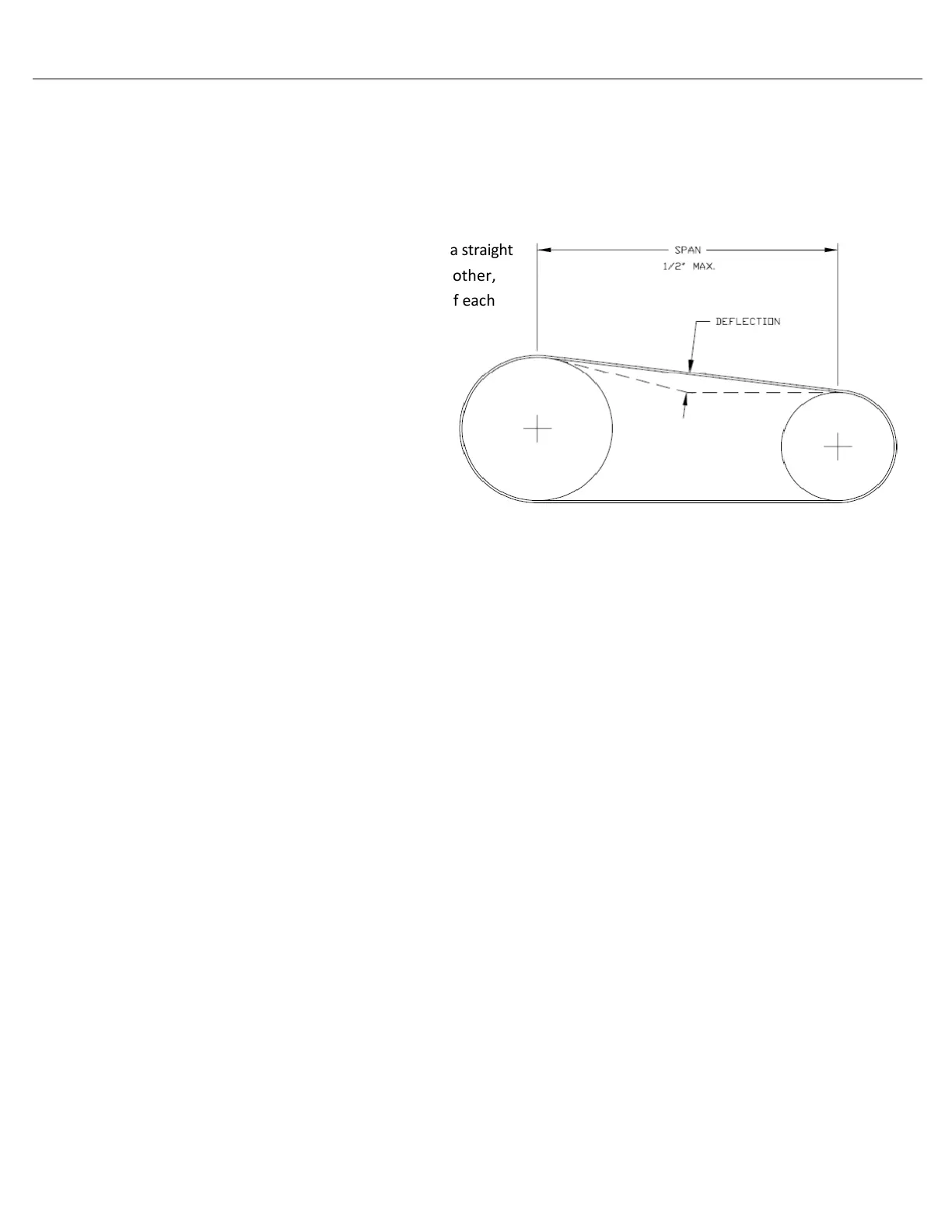

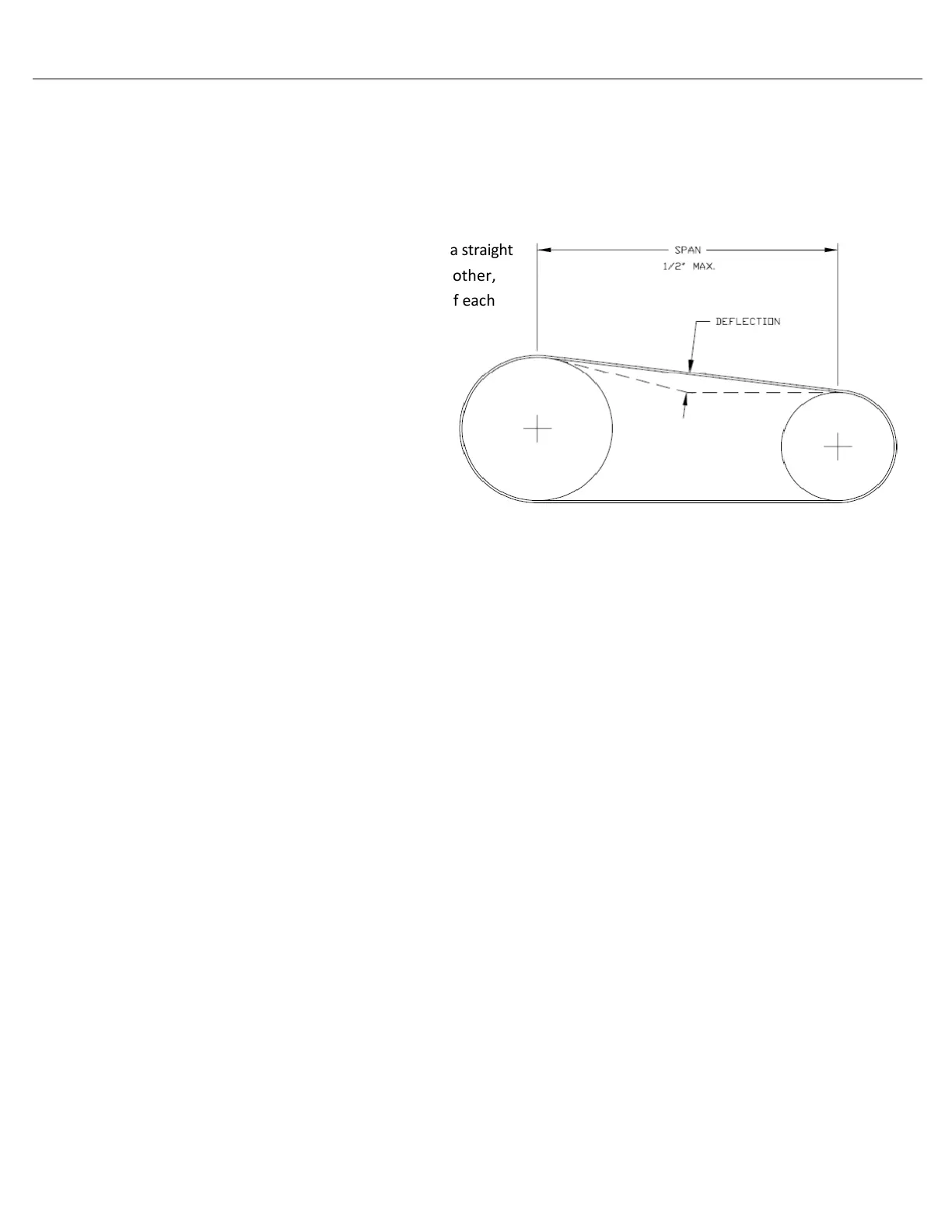

2. Measure the belt span (see figure on right).

3. Using a spring scale, apply a perpendicular force to any

ONE of the belts at the mid point of the span.

4. Calculate the force (lbs.) required to deflect any one

of the belts 1/64th of an inch for every inch of span.

For example: the deflection for a 32-inch span would

be 1/64th of an inch times 32 or 1/2 of an inch.

5. The motor position should be adjusted until the actual deflection force matches the distance of deflection referenced in

item 4 above.

6. There will normally be a drop-in belt tension during the first 24 to 48 hours of operation due to belt stretch and the

belts seating themselves in the sheave grooves. After this initial run in period the machine should be stopped, and the

belts should be rechecked for tension. The motor position should be adjusted until the deflection force matches the

values in column "B".

7. Do not over tension belts as this can significantly reduce belt life and/or bearing life.

Loading...

Loading...