28

508.366.1488 | www.semshred.com

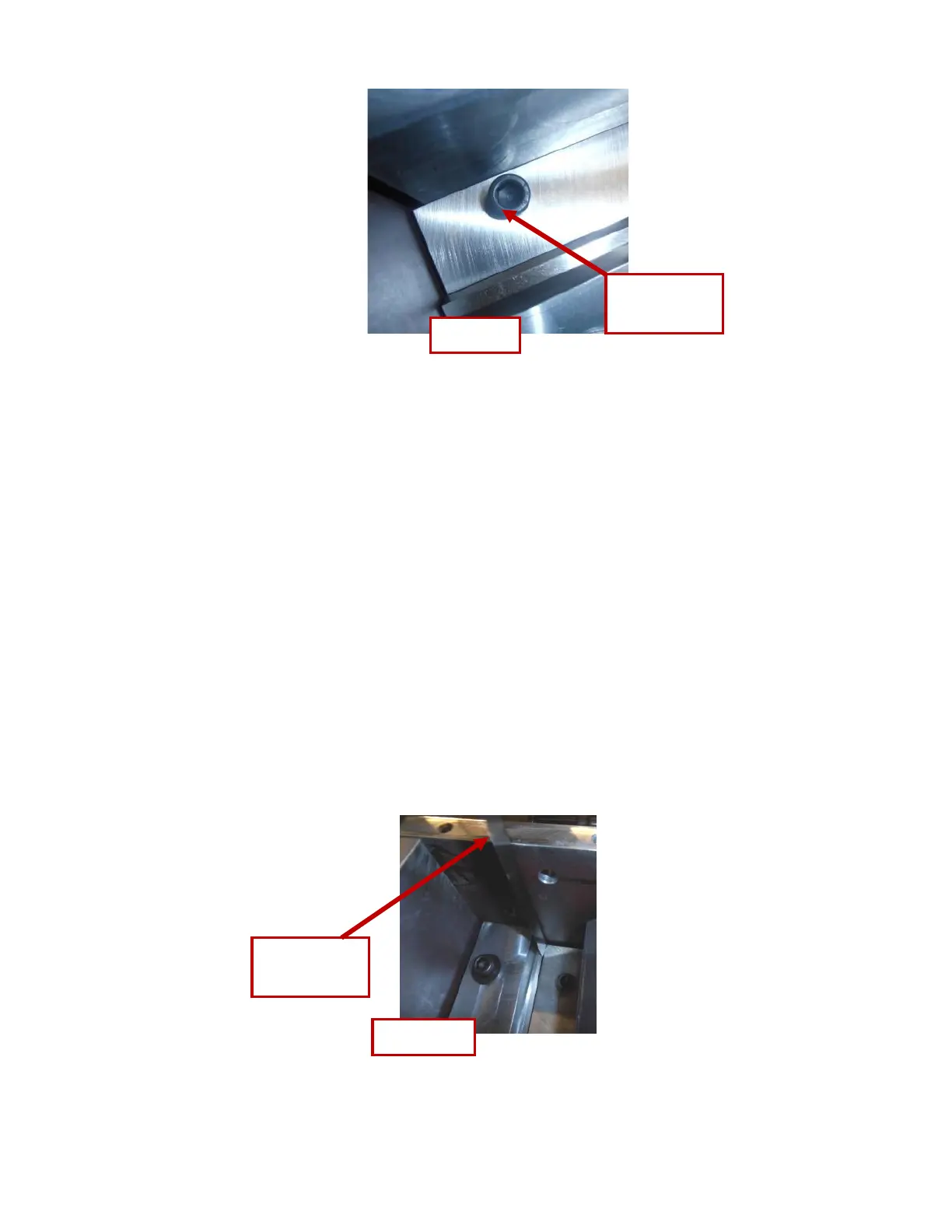

8. Torque rotor knives to 50-55ft./lbs. Requires torque wrench and 5/16” Allen drive socket bit

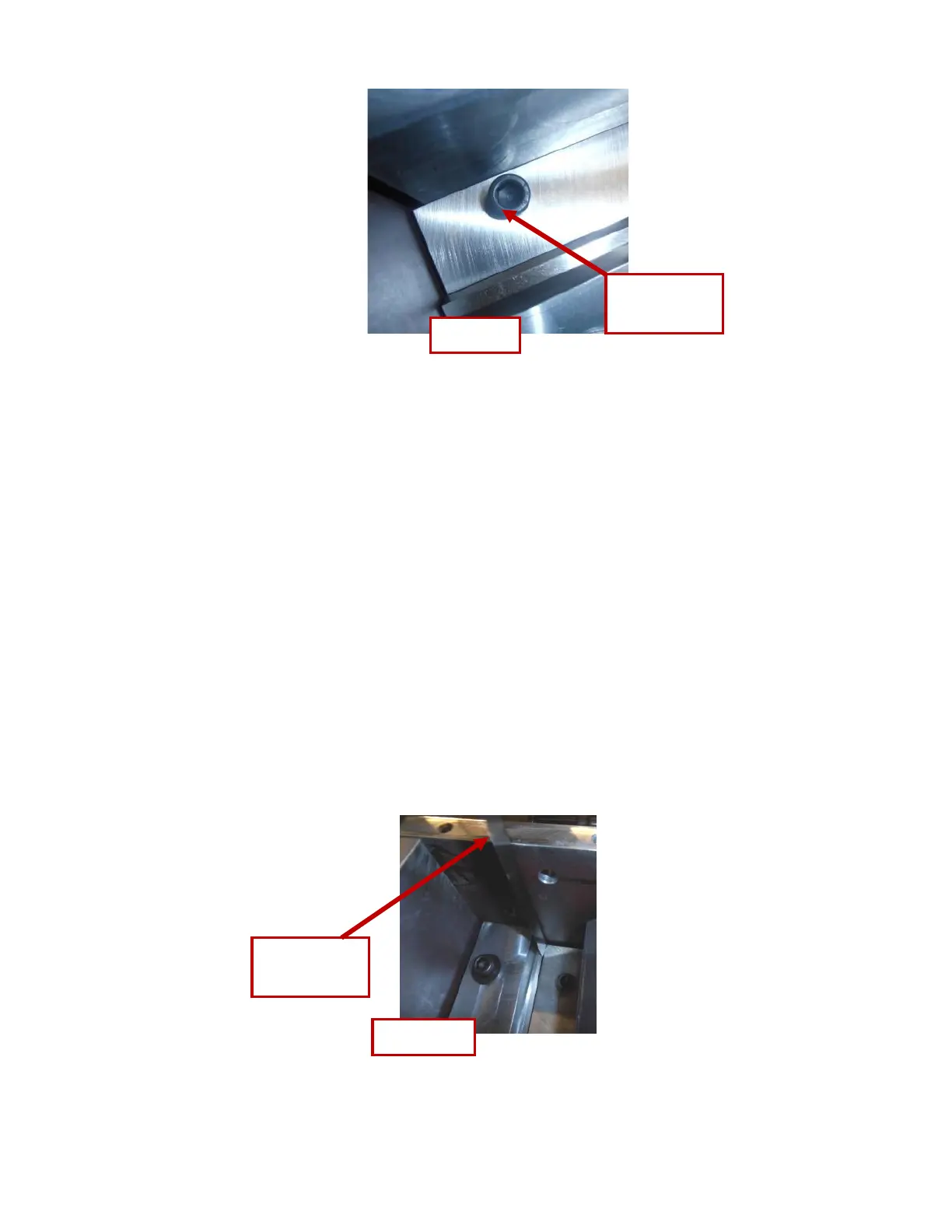

9. Set clearance between rotor and bed knives to .005” using adjustment screws and a feeler gauge, rotating the

knives in reverse (clockwise) so “flat to flat” contact will not cut feeler gauge.

o Requires 7/16” wrench and .005” feeler gauge.

o Process will need to be repeated until proper clearance is achieved.

o You will hear a light “knock” while spinning the rotor when one or two rotor knives come into contact

with the feeler gauge. This indicates proper clearance.

§ There should be little resistance, just a noise.

§ If the rotor stops, there is too little clearance.

§ The knocking only occurs on the longest of the three rotor knives, occasionally it will occur for

two knives.

o Check clearance in front of each bed knife bolt. The “knocking” should occur either in the middle OR on

the two outside bed knife bolts.

o Double check clearance after tightening bolts as gap should be checked on each knife on rotor and

across the whole surface of each knife.

Loading...

Loading...