12

Section 2 Model 7000 Series Turbine Flowmeter

Bolt Size/Torque Requirements

Bolt sizes vary with meter size and ange rating. See Table 2.4 for bolt speci-

cations recommended in ASME B16.5-2003.

Torque requirement vary with meter size, threads, and tting/nut material. See

Table 2.2 for recommended torque values.

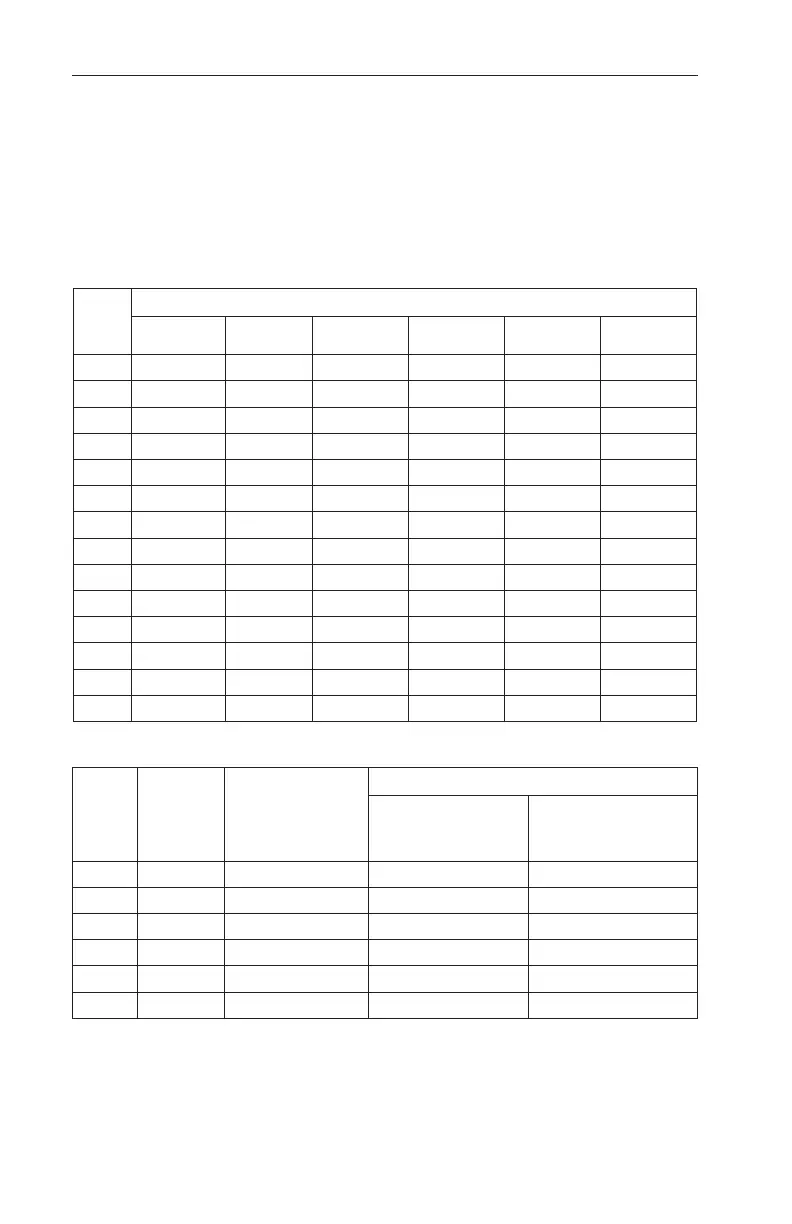

Table2.1—RecommendedBoltSizes

Meter

Size

(in.)

FlangeRating

150LB 300LB 600LB 900LB 1500LB 2500LB

1/2 2-1/4x1/2 2-1/2x1/2 3x1/2 4-1/4x3/4 4-1/4x3/4 —

3/4 2-1/2x1/2 3x5/8 3-1/2x5/8 4-1/2x3/4 4-1/2x3/4 —

1 2-1/2x1/2 3x5/8 3-1/2x5/8 5x7/8 5x7/8 5-1/4x7/8

1-1/4 2-3/4x1/2 3-1/4x5/8 3-3/4x5/8 5x7/8 5x7/8 5-3/4x1

1-1/2 2-3/4x1/2 3-1/2x3/4 4-1/4x3/4 5-1/2x1 5-1/2x1 6-1/2x1-1/8

2 3-1/4x5/8 3-1/2x5/8 4-1/4x5/8 5-3/4x7/8 5-3/4x7/8 6-3/4x1

2-1/2 3-1/2x5/8 4x3/4 4-3/4x3/4 6-1/4x1 6-1/4x1 7-1/2x1-1/8

3 3-1/2x5/8 4-1/4x3/4 5x3/4 5-3/4x7/8 7x1-1/8 8-1/2x1-1/4

4 3-1/2x5/8 4-1/2x3/4 5-3/4x7/8 6-3/4x1-1/8 7-3/4x1-1/4 9-3/4x1-1/2

5 3-3/4x3/4 4-3/4x3/4 6-1/2x1 7-1/2x1-1/4 9-3/4x1-1/2 11-1/2x1-3/4

6 4x3/4 4-3/4x3/4 6-3/4x1 7-1/2x1-1/8 10-1/4x1-3/8 13-1/2x2

8 4-1/4x3/4 5-1/2x7/8 7-1/2x1-1/8 8-3/4x1-3/8 11-1/2x1-5/8 15x2

10 4-1/2x7/8 6-1/4x1 8-1/2x1-1/4 9-1/4x1-3/8 13-1/4x1-7/8 19x2-1/2

12 4-3/4x7/8 6-3/4x1-1/8 8-3/4x1-1/4 10x1-3/8 14-3/4x2 21x2-3/4

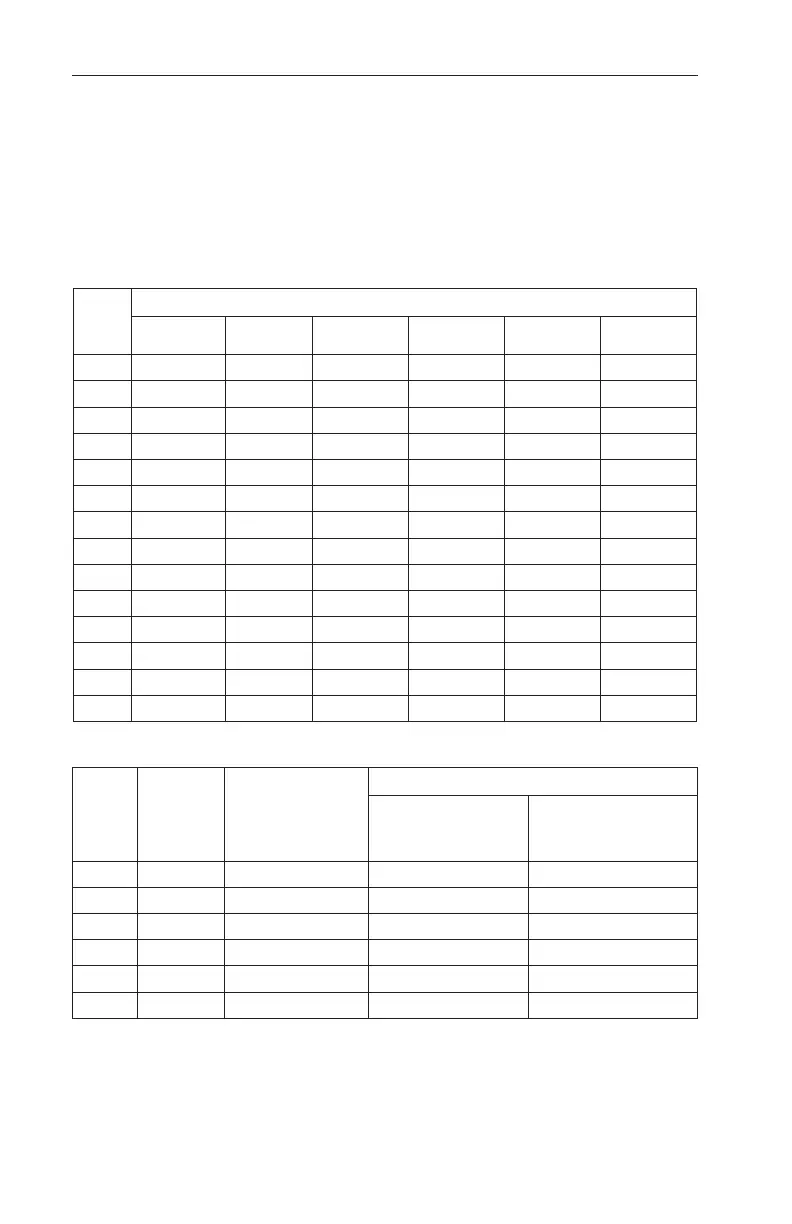

Table2.2—TorqueValues

Dash

No.

O.D.

Tubing

(inches)

FittingsThreads

(UniedThreads

Class 3A may be

used)

Torque*inch-lbs(N-m)

Aluminum & Other

Non-Ferrous Alloy

Fittings&Nuts

Steel & Other

Ferrous Alloy

Fittings&Nuts

8 1/2 3/4-16 NF-3 150-200 (17-22.6) 220-300 (24.8-33.9)

10 5/8 7/8-14 NF-3 205-275 (23.2-31) 300-410 (33.9-46.3)

12 3/4 1-1/16-12 N-3 300-400 (33.9-45.2) 450-600 (50.8-67.8)

16 1 1-5/16-12 N-3 450-600 (50.8-67.8) 675-900 (76.3-101.7)

20 1-1/4 1-5/8-12 N-3 540-720 (61-81.3) 825-1100 (93.2-124.3)

24 1-1/2 1-7/8-12 N-3 680-900 (76.8-101.7) 1010-1350 (114-152.3)

Notes: Completely dry nuts should be torqued to the high value given. When nuts are

lubricated, they should be torqued to the lower value given.

* The applicable torque is determined on the basis of the nut and related tting re-

gardless of the material that the tting passes through.

Loading...

Loading...