MX-C250 SIMULATION 6 – 32

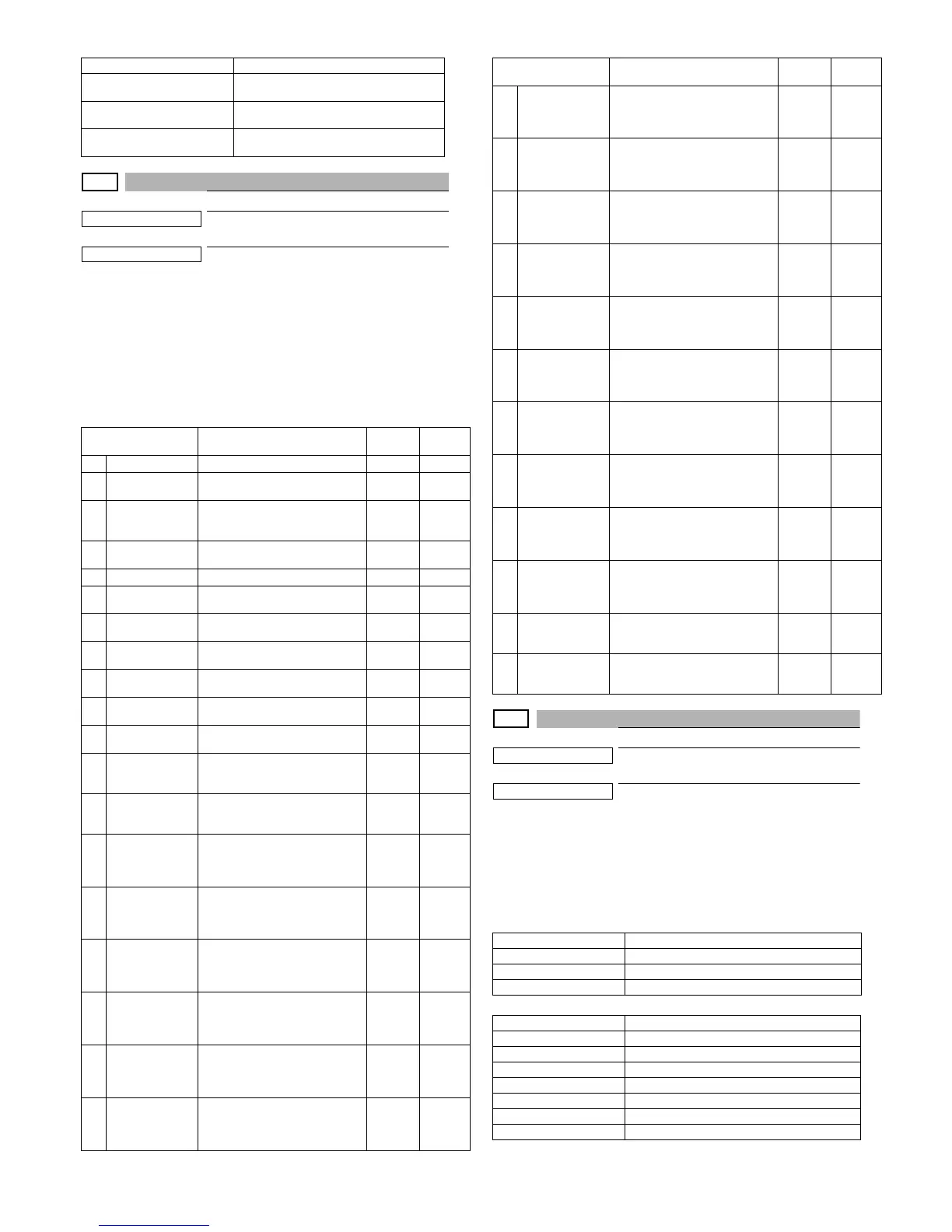

44-4

Purpose

Setting

Function (Purpose)

Used to set the conditions of the high den-

sity process control operation.

Section

Process

Operation/Procedure

1) Select an item to be set with Arrow keys.

2) Enter the set value with 10 keys.

3) Press [OK]/[START] key.

The set value in step 2) is saved.

NOTE:

Set the items to the default values unless a change is spe-

cially required.

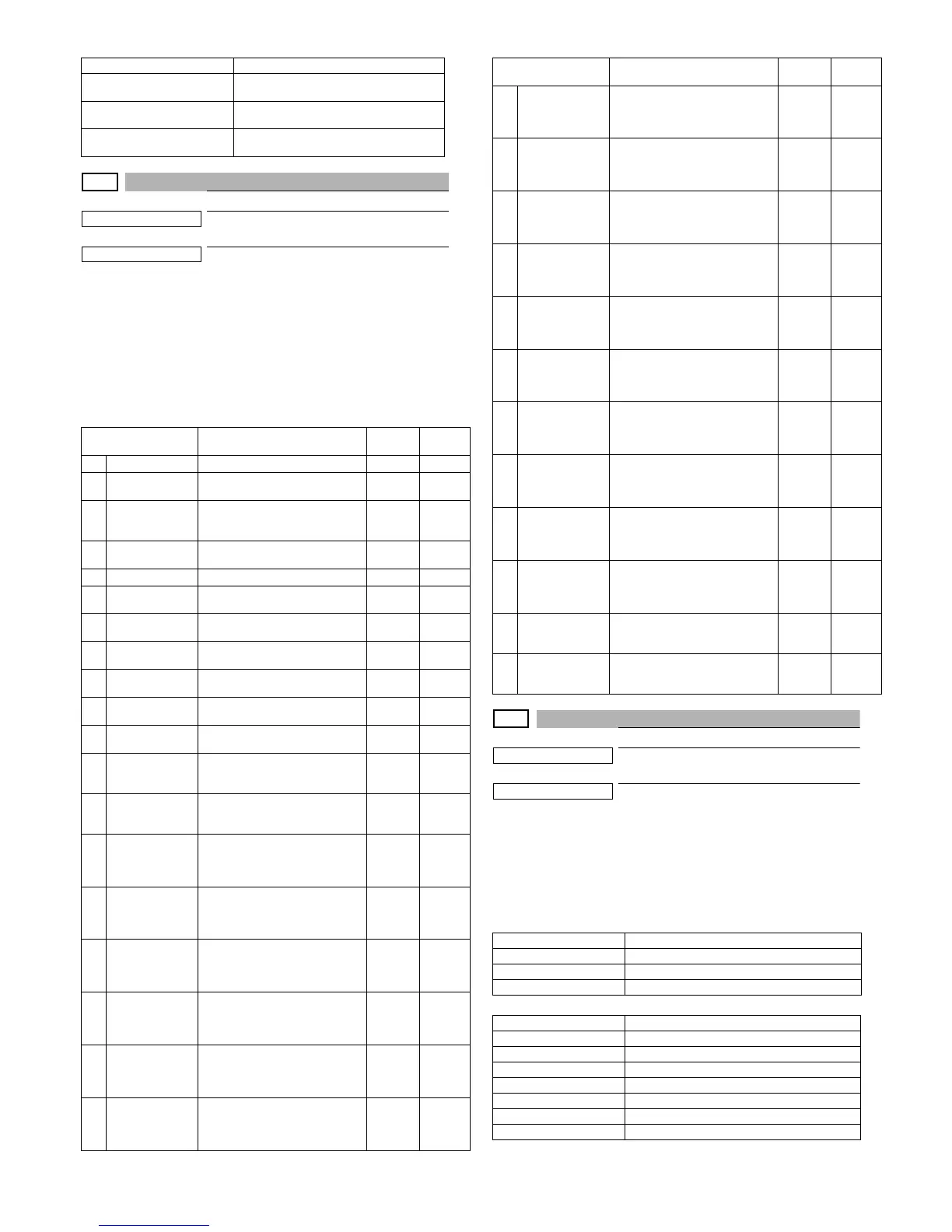

44-6

Purpose

Adjustment

Function (Purpose)

Used to execute the high density process

control forcibly.

Section

Process

Operation/Procedure

When [OK]/[START] key is pressed, the adjustment is exe-

cuted automatically.

After completion of the adjustment, the adjustment result is

displayed. (Refer to the table below.)

If the adjustment is not executed normally, "ERROR" is dis-

played.

REG_R_LED_ADJ Registration sensor R adjustment abnor-

mality

REG_F_GRND F registration basis material reading

abnormality

REG_R_GRND R registration basis material reading

abnormality

Item/Display Content

Setting

range

Default

value

1 PCS TARGET Sensor target set value

1 - 255 204

2PCS ADJ LIM

Sensor adjustment target limit

value

1 - 255 8

3BELT G DIF

Effective difference between the

belt circuit substrate upper and

lower limit values

1 - 255 1

4 B_BK STD DIF

Bias (for black) Target calcula-

tion difference

0 - 255 0

5 B PAT INT Patch bias output interval

1 - 255 60

6Y TAR ID

Patch density standard value

(yellow)

1 - 255 45

7 M TAR ID

Patch density standard value

(magenta)

1 - 255 50

8 C TAR ID

Patch density standard value

(cyan)

1 - 255 50

9K TAR ID

Patch density standard value

(black)

1 - 255 45

10 HV BK_GR LIM

Patch position substrate light

receiving effective range value

1 - 255 60

11

LED ADJ

ROUGH

LED radiation quantity adjust-

ment rough 1step

1 - 255 5

12

LED ADJ

ROUGH

UPPER

LED radiation quantity adjust-

ment rough 1step execution

threshold level upper

1 - 255 240

13

LED ADJ

ROUGH

LOWER

LED radiation quantity adjust-

ment rough 1step execution

threshold level lower

1 - 255 140

14

K_PAT TAR-

GET UPPER 1

Simplified process control solid-

patch transition judgment to high

density process control upper

limitation 1 (K-patch)

1 - 255 10

15

K_PAT TAR-

GET LOWER 1

Simplified process control solid-

patch transition judgment to high

density process control lower

limitation 1 (K-patch)

1 - 255 10

16

K_PAT TAR-

GET UPPER 2

Simplified process control solid-

patch transition judgment to high

density process control upper

limitation 2 (K-patch)

1 - 255 15

17

K_PAT TAR-

GET LOWER 2

Simplified process control solid-

patch transition judgment to high

density process control lower

limitation 2 (K-patch)

1 - 255 15

18

K_HT TARGET

UPPER 1

Simplified process control half-

tone-patch transition judgment

to high density process control

upper limitation 1 (K-patch)

1 - 255 10

19

K_HT TARGET

LOWER 1

Simplified process control half-

tone-patch transition judgment

to high density process control

lower limitation 1 (K-patch)

1 - 255 10

Error name Error content

20

K_HT TARGET

UPPER 2

Simplified process control half-

tone-patch transition judgment

to high density process control

upper limitation 2 (K-patch)

1 - 255 15

21

K_HT TARGET

LOWER 2

Simplified process control half-

tone-patch transition judgment

to high density process control

lower limitation 2 (K-patch)

1 - 255 15

22

CL_PAT TAR-

GET UPPER 1

Simplified process control solid-

patch transition judgment to high

density process control upper

limitation 1 (CL-patch)

1 - 255 10

23

CL_PAT TAR-

GET LOWER 1

Simplified process control solid-

patch transition judgment to high

density process control lower

limitation 1 (CL-patch)

1 - 255 10

24

CL_PAT TAR-

GET UPPER 2

Simplified process control solid-

patch transition judgment to high

density process control upper

limitation 2 (CL-patch)

1 - 255 15

25

CL_PAT TAR-

GET LOWER 2

Simplified process control solid-

patch transition judgment to high

density process control lower

limitation 2 (CL-patch)

1 - 255 15

26

CL_HT TAR-

GET UPPER 1

Simplified process control half-

tone-patch transition judgment

to high density process control

upper limitation 1 (CL-patch)

1 - 255 10

27

CL_HT TAR-

GET LOWER 1

Simplified process control half-

tone-patch transition judgment

to high density process control

lower limitation 1 (CL-patch)

1 - 255 10

28

CL_HT TAR-

GET UPPER 2

Simplified process control half-

tone-patch transition judgment

to high density process control

upper limitation 2 (CL-patch)

1 - 255 15

29

CL_HT TAR-

GET LOWER 2

Simplified process control half-

tone-patch transition judgment

to high density process control

lower limitation 2 (CL-patch)

1 - 255 15

30

SP_PAT COEF

UPP DIF

Simplified process control den-

sity coefficient upper threshold

level

1 - 255 10

31

SP_PAT COEF

LOW DIF

Simplified process control den-

sity coefficient lower threshold

level

1 - 255 10

Result display Content description

COMPLETE Normal complete

ERROR Abnormal end

INTERRUPTION Forcible interruption

Details of error display Content description

CL_SEN_ADJ_ERR Color sensor adjustment abnormality

BK_SEN_ADJ_ERR Black sensor adjustment abnormality

K_HV_ERR K high density process control abnormality

C_HV_ERR C high density process control abnormality

M_HV_ERR M high density process control abnormality

Y_HV _ERR Y high density process control abnormality

TIMEOUT_ERR Time out

Item/Display Content

Setting

range

Default

value

Loading...

Loading...