MX-C250 SIMULATION 6 – 17

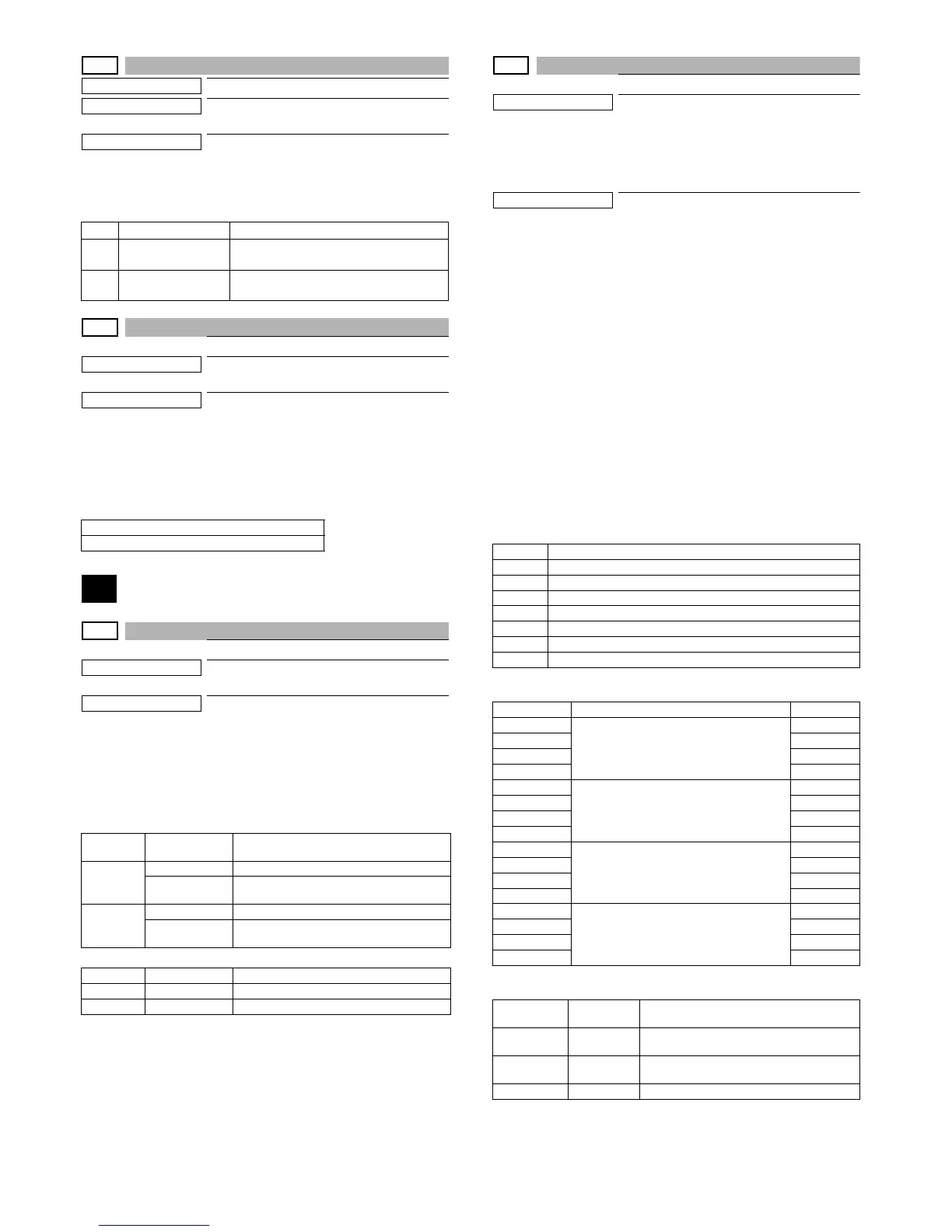

24-15

Purpose

Data clear

Function (Purpose)

Used to clear the counters related to the

scan mode and the image send.

Section

Operation/Procedure

1) Select the item to be cleared with 10 keys.

2) Press [OK]/[START] key.

24-35

Purpose

Data clear

Function (Purpose)

Used to clear the usage number of toner

cartridge.

Section

Operation/Procedure

1) Select the item to be cleared with 10 keys.

2) Press [OK]/[START] key.

3) Press [OK]/[START] key.

The target counter is cleared.

25

25-1

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the devel-

oping section.

Section

Process (Developing section)

Operation/Procedure

1) Select the process speed with 10 keys.

2) Press [OK]/[START] key.

The developing motor and the OPC drum motor rotate for 3

minutes and the output level of the toner density sensor is dis-

played.

25-2

Purpose

Setting

Function (Purpose)

Display the value of the selected sensor

and register the toner density control value,

toner density control voltage, developer

adjustment area and sensitivity adjustment

value by driving the all drum motors.(Auto-

matic adjustment)

Section

Image process (Photoconductor/Develop-

ing/Transfer/Cleaning)

Operation/Procedure

1) Select the item with 10 keys.

2) Press [OK]/[START] key.

The developing motor rotates for 1 minutes and 30 seconds, and

the toner density sensor makes sampling of the toner density. The

detected level is displayed.

After stopping the developing motor, the average value of the toner

density sampling results is set as the reference toner density con-

trol level.

NOTE:

When the above operation is interrupted on the way, the

reference toner concentration level is not set. Also when

error code of EE-EC, EE-EL or EE-EU is displayed, the ref-

erence toner density level is not set normally.

Do not execute this simulation except when new developer is sup-

plied. If it is executed in other cases, undertoner or overtone may

occur, causing a trouble.

Display during operation

Display after completion of the adjustment

Display and condition in case of an error

No. Item/Display Content

1 NET SCN ORG B/W

Network scanner document read quantity

counter (B/W scan job)

2 NET SCN ORG CL

Network scanner document read quantity

counter (COLOR scan job)

Item

TN END CNT CLR

Process

speed

Sensor Name Contents

MIDDLE

ADJ_M Toner density sensor (K,C,M,Y in turn)

VO_M

Toner density sensor control voltage level

(K,C,M,Y in turn)

LOW

ADJ_L Toner density sensor (K,C,M,Y in turn)

VO_L

Toner density sensor control voltage level

(K,C,M,Y in turn)

No Item/Display Contents

1 MIDDLE Process speed : Middle

2 LOW Process speed : Low

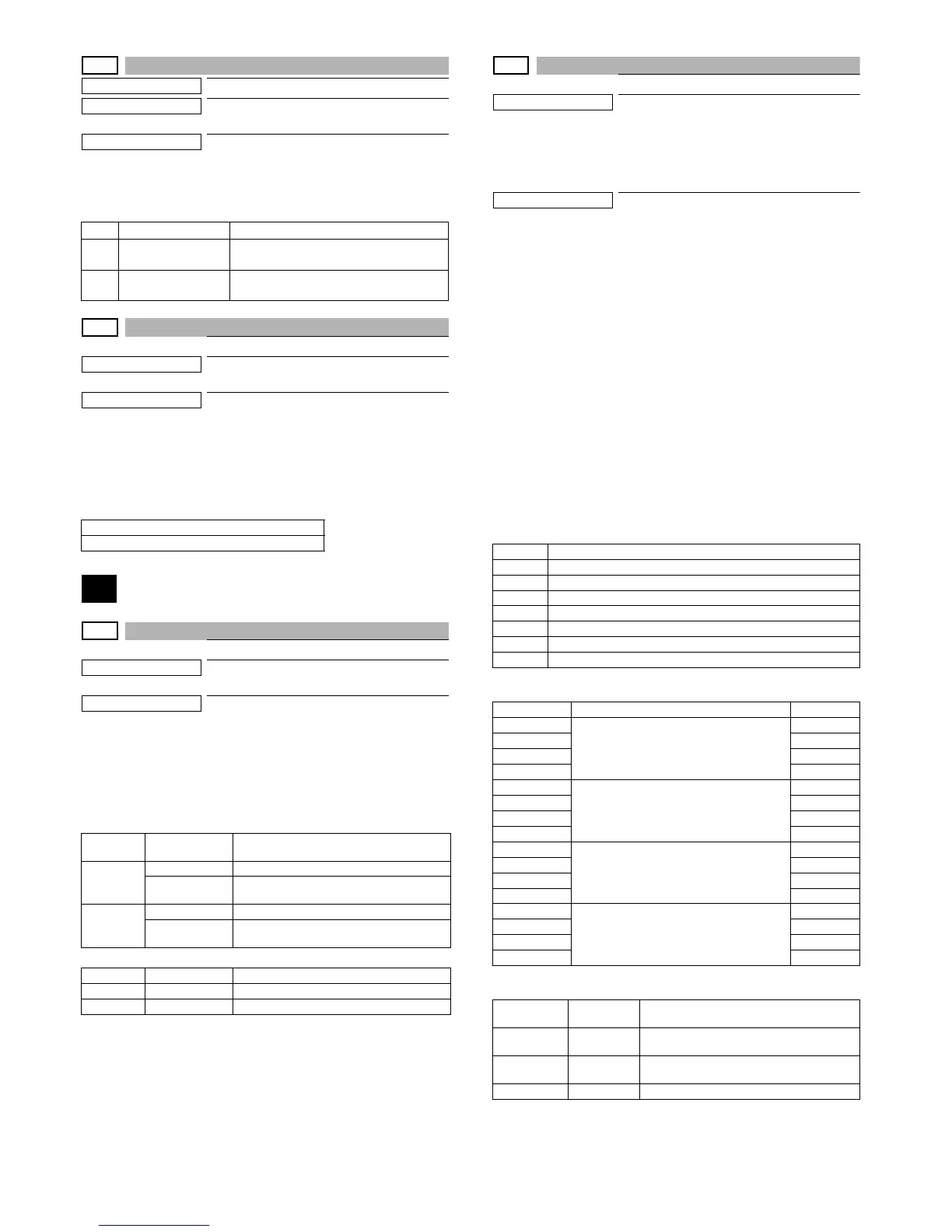

TCS_K Toner density sensor control voltage level K

TCS_C Toner density sensor control voltage level C

TCS_M Toner density sensor control voltage level M

TCS_Y Toner density sensor control voltage level Y

TSG_K Toner density sensor control level K

TSG_C Toner density sensor control level C

TSG_M Toner density sensor control level M

TSG_Y Toner density sensor control level Y

Display Mode Range

ADJ_L_K Toner density control adjustment value in

the low speed process mode

1 - 255

ADJ_L_C 1 - 255

ADJ_L_M 1 - 255

ADJ_L_Y 1 - 255

ADJ_M_K Toner density control adjustment value in

the medium speed process mode

1 - 255

ADJ_M_C 1 - 255

ADJ_M_M 1 - 255

ADJ_M_Y 1 - 255

VO_L_K Toner density sensor control voltage level

in the low speed process mode

1 - 255

VO_L_C 1 - 255

VO_L_M 1 - 255

VO_L_Y 1 - 255

VO_M_K Toner density sensor control voltage level

in the medium speed process mode

1 - 255

VO_M_C 1 - 255

VO_M_M 1 - 255

VO_M_Y 1 - 255

Error dis-

play

Error name Error details

EE-EL EL error

The sensor output level is lower than 77, or

the control voltage level is higher than 207.

EE-EU EU error

The sensor output level is higher then 177,

or the control voltage level is lower than 52.

EE-EC EC error The sensor output level is out of 128+/- 3.

Loading...

Loading...