MX-M182 SIMULATIONS 7-31

43 13 Paper interval control allow/inhibit setting

Used to change the paper feed timing of 21st sheet or later to A3 or WLT (depending on the destination

setting) when in multi copy/print of narrow width sheets.

When this simulation is executed, the current set number is displayed. Enter a code number and press

[START] key. The entered number is saved in the EEPROM and the machine returns to the sub code input

window.

<Applicable paper>

1) Cassette paper feed: A4R,B5R,8-1/2"x14",8-1/2"x13",8-1/2"x11",A5,INV

2) Manual paper feed: A4R,B5R,8-1/2"x14",8-1/2"x13",8-1/2"x11",A5,INV,16KRÅ

* A5 is applicable to manual paper fed only in EX Japan AB series.

Default:

0

44 01 Enable/Disable setting of toner density control correction

Enable/Disable of toner density control correction is set.

When this simulation is executed, the list of the modes and the current set value are displayed on the LCD.

"Select an item to be changed with the cross key, and change the set value to the required value.

(1=ON [Enable], 0=OFF [Disable])"

When [OK] key or [START] key is pressed, the setting is saved to the EEPROM.

<Descriptions of each correction>

Print ratio correction

In this correction, the toner supply interval is determined according to the print ratio to prevent against over-

toner.

Note for corrections marked with

Since "Drip supply" and "Purge process" are simulations for analysis, do not set them to "1" [Enable].

If they are set to "1" [Enable], the toner density rises or falls abnormally and developer failure or toner

dispersion occurs.

If they are set to "1" [Enable] erroneously, developer must be replaced, and the inside of the machine and

the process unit must be cleaned.

Unconditional toner supply

When the developing unit and the drum unit are rotating, a small quantity of toner is consumed. For assuring

this operation, toner is supplied according to the rotation time of the developing unit.

Default:

COV: 1

LIFE:

0

(18/20cpm machine)

1 (23cpm machine)

DRIP: 0

BETA: 0

UNCONDITIONAL:

1

16 Toner density control data check and toner density correction quantity display

The output value of the ATC sensor is checked, and the toner density control correction quantity is displayed

on the LCD.

[CA] key: Exits the simulation mode.

[INTERRUPT] key: Shifts to the sub code input window.

Main

code

Sub

code

Contents Remark

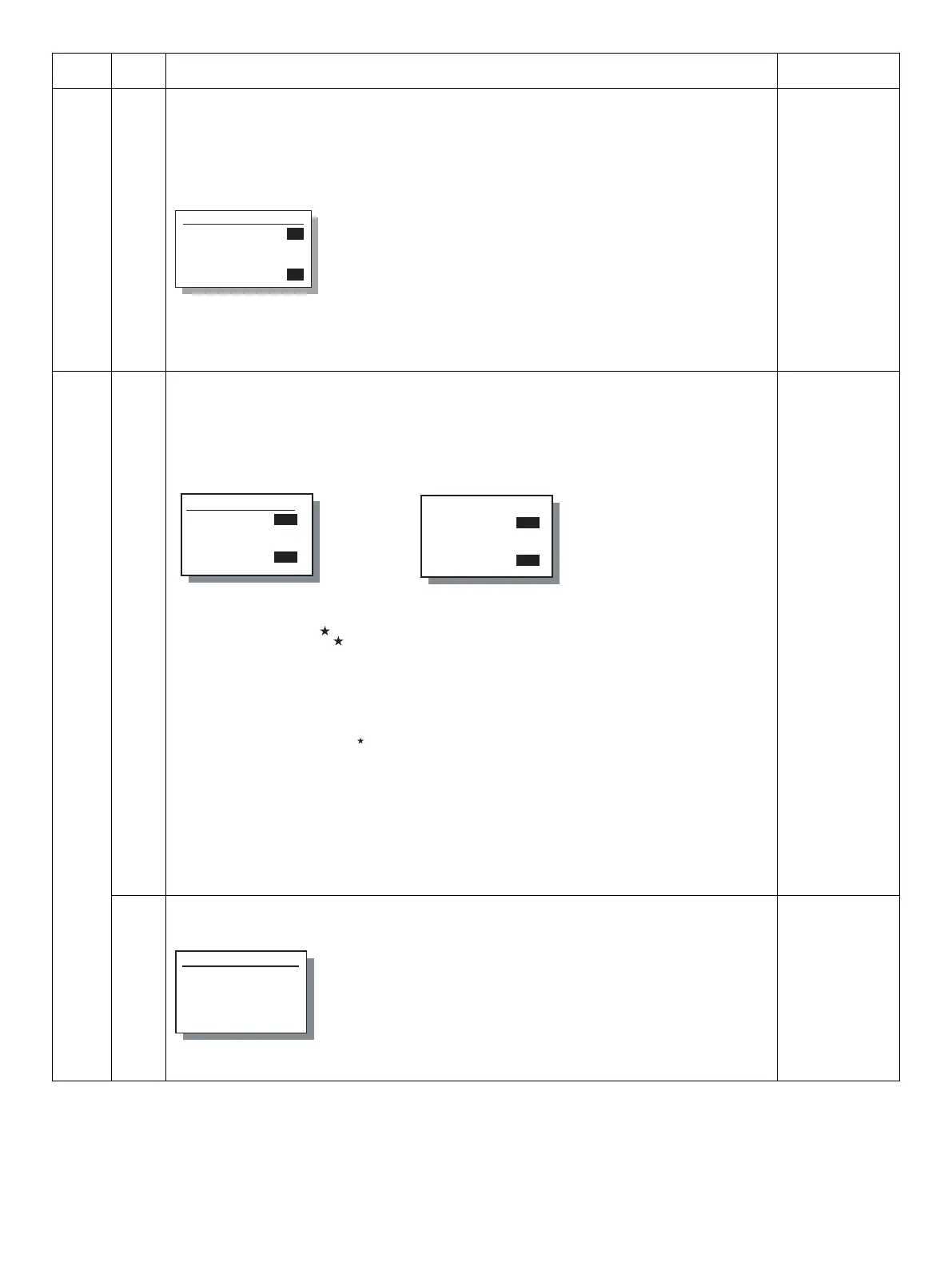

Sim43-13 PICK INTVL

1:PICK INTVL

[ 0-1]

0

0

Code: Setting

0: Disable (Default)

1: Enable

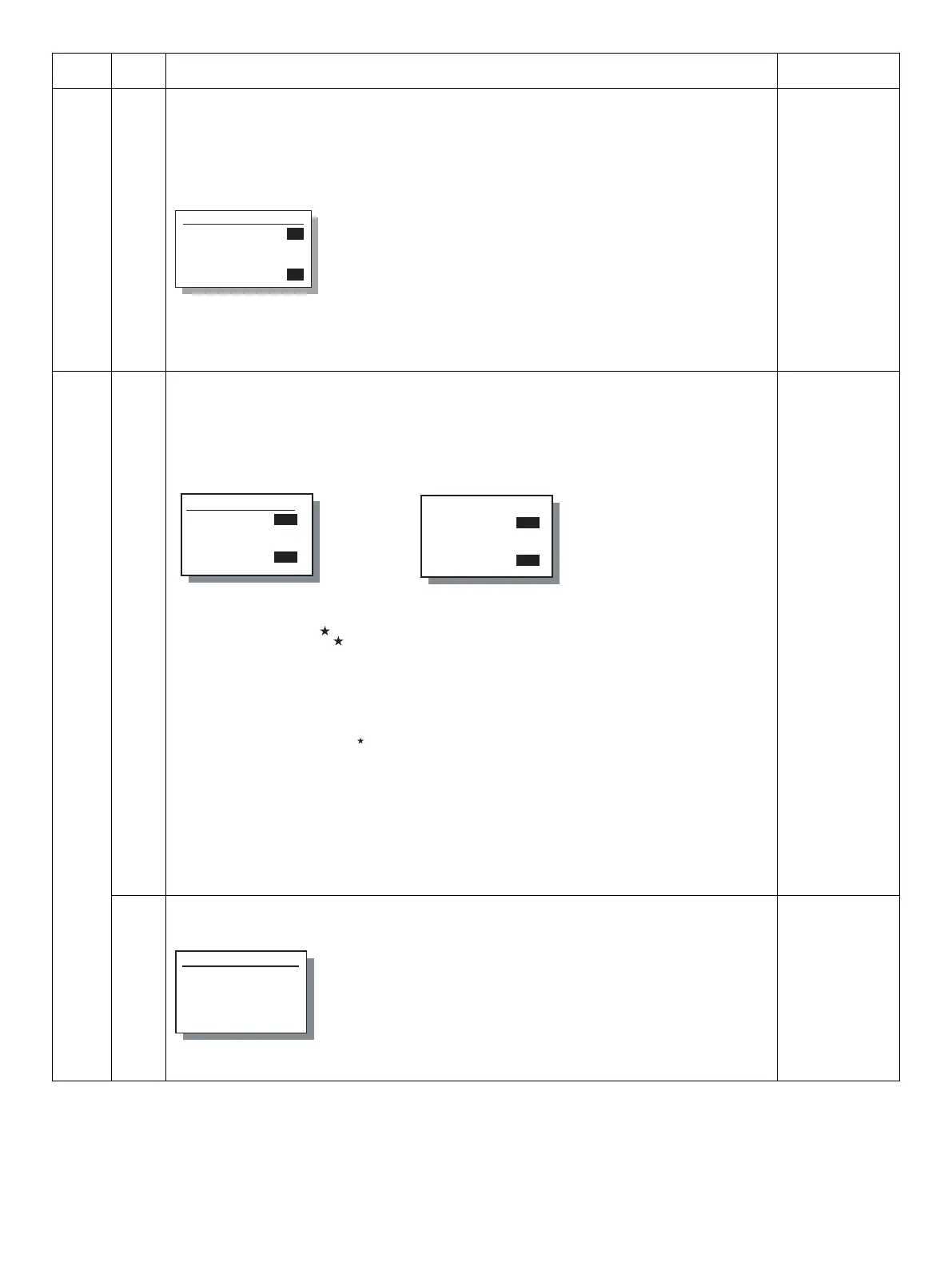

Sim44-1 TONER CONT

1:COV

2:LIFE

3:DRIP

1/2 [ 0- 1]

0

0

0

0

Sim44-1 TONER CONT

4:BETA

5:UNCONDITIONAL

2/2 [ 0- 1]

0

0

0

0

Display mode : Setting mode Display : Setting

COV

LIFE

DRIP

BETA

UNCONDITIONAL

: Print ratio correction

: Life correction

: Drip supply

: Purge process

: Unconditional toner supply

0 : Disable

1 : Enable

Name

TONER DEN_LT

TONER DEN_ST

:Display content

:Current ATC sensor value

:ATC reference value with life correction

quantity added

Sim44-16 TONER DISP

1:TONER DEN_LT

nnn

2:TONER DEN_ST

nnn

Loading...

Loading...