– 9 –

XL-HP700

CD ERROR CODE DESCRIPTION

Error Explanation

01

When Pickup set inner position, inner switch

cannot detect 'ON' level for 10 secs.

10*

CAM error. Can't detect CAM switch when CAM is

moving.

11*

When it detect CAM operation error during initialize

process.

20*

TRAY error. Can't detect TRAY switch when TRAY is

moving.

21*

When it detect TRAY operation error during initialize

process.

22*

When it detect invalid TRAY switch during normal

operation.

23*

When it detect invalid TRAY switch during initialize

procecss.

31

When it change to CD function, DSP cannot read

initial data.

Test Stage

Frequency

Frequency

Display

Setting/

Adjusting

Parts

Instrument

Connection

CD SECTION

••

••

•

AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

*1. Input: Antenna Output: TP302

*2. Input: Antenna Output: TP301

TUNER SECTION

fL: Low-range frequency

fH: High-range frequency

AM IF 450 kHz 1,602 kHz T351 *1

AM Band — 531 kHz (fL): T306 *2

Coverage 1.1 ± 0.1 V

AM Tracking 990 kHz 990 kHz (fL): T303 *1

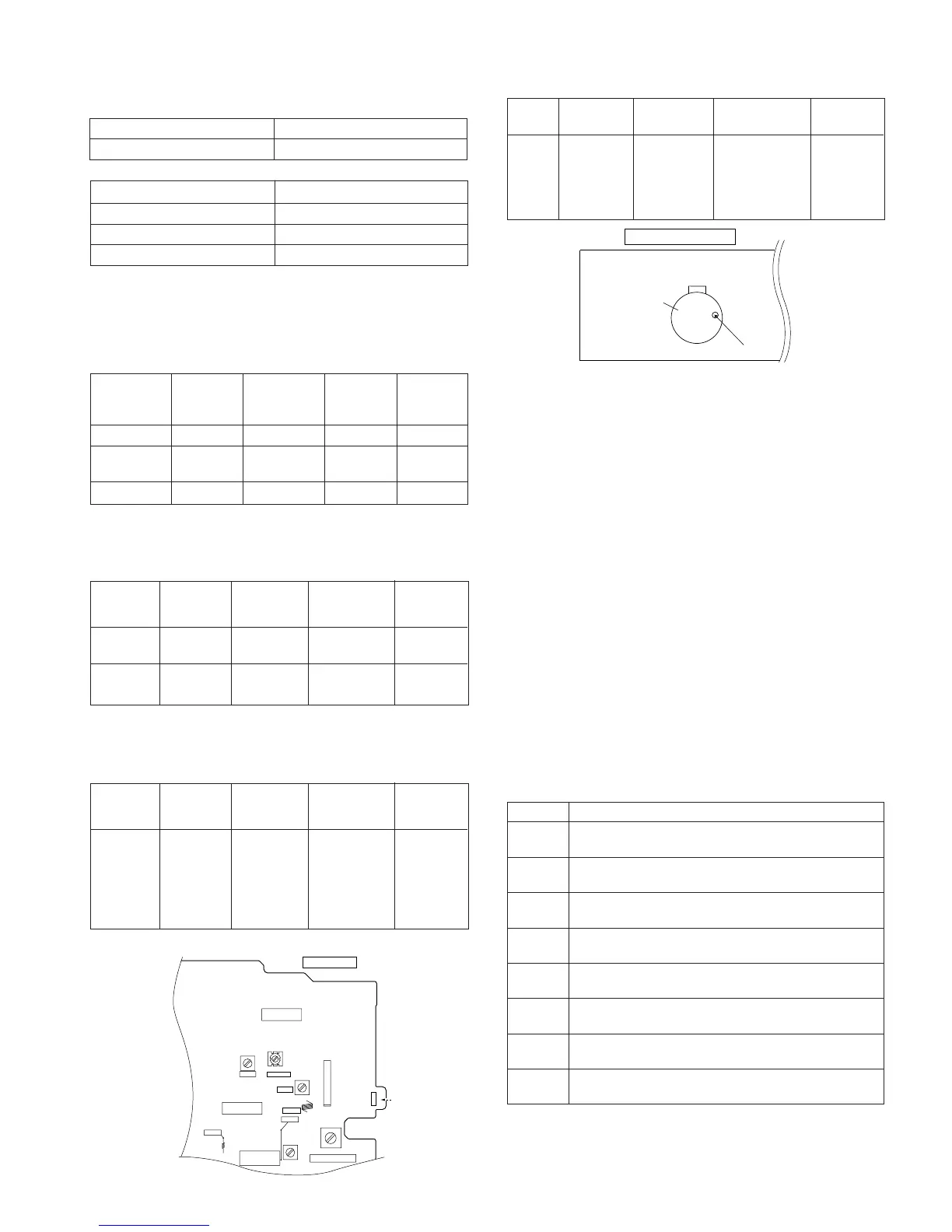

Figure 9-2 ADJUSTMENT POINTS

Items adjusted automatically

(1) Offset adjustment (The offset voltage between the head

amplifier output and the VREF reference voltage is

compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

(2) Tracking balance adjustment

(3) Gain adjustment (The gain is compensated inside the IC

so that the loop gain at the gain crossover frequency will

be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

• Adjustment

Since this CD system incorporates the following automatic

adjustment functions, readjustment is not needed when

replacing the pickup. Therefore, different PWBs and pickups

can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each disc

can be performed under optimum conditions.

R357

FM/AM

LOOP

ANTENNA

IC302

T351

IC303

T303

T306

T301

T302

L312

CNP302

IC301

MAIN PWB-A1

TP302

TP301

AM TRACKING fL

AM BAND

COVERAGE fL

AM IF

FM IF

FM RF

FM OSC

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed instead of

'ER-CD**'. 'ER-CD**' display will only be displayed when error

had been detected for the 5th times.

ADJUSTMENT

MECHANISM SECTION

••

••

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Over 80 g

• Torque Check

Torque Meter

Play: TW-2111 30 to 80 g.cm

Fast forward: TW-2231 70 to 180 g.cm

Rewind: TW-2231 70 to 180 g.cm

Specified Value

Specified

Value

Adjusting

Point

Instrument

Connection

Test Tape

Normal MTT-111 Variable 3,000 ± 30 Hz Speaker

speed Resistor in Terminal

motor. (Load

resistance:

6 ohms)

••

••

• Tape Speed

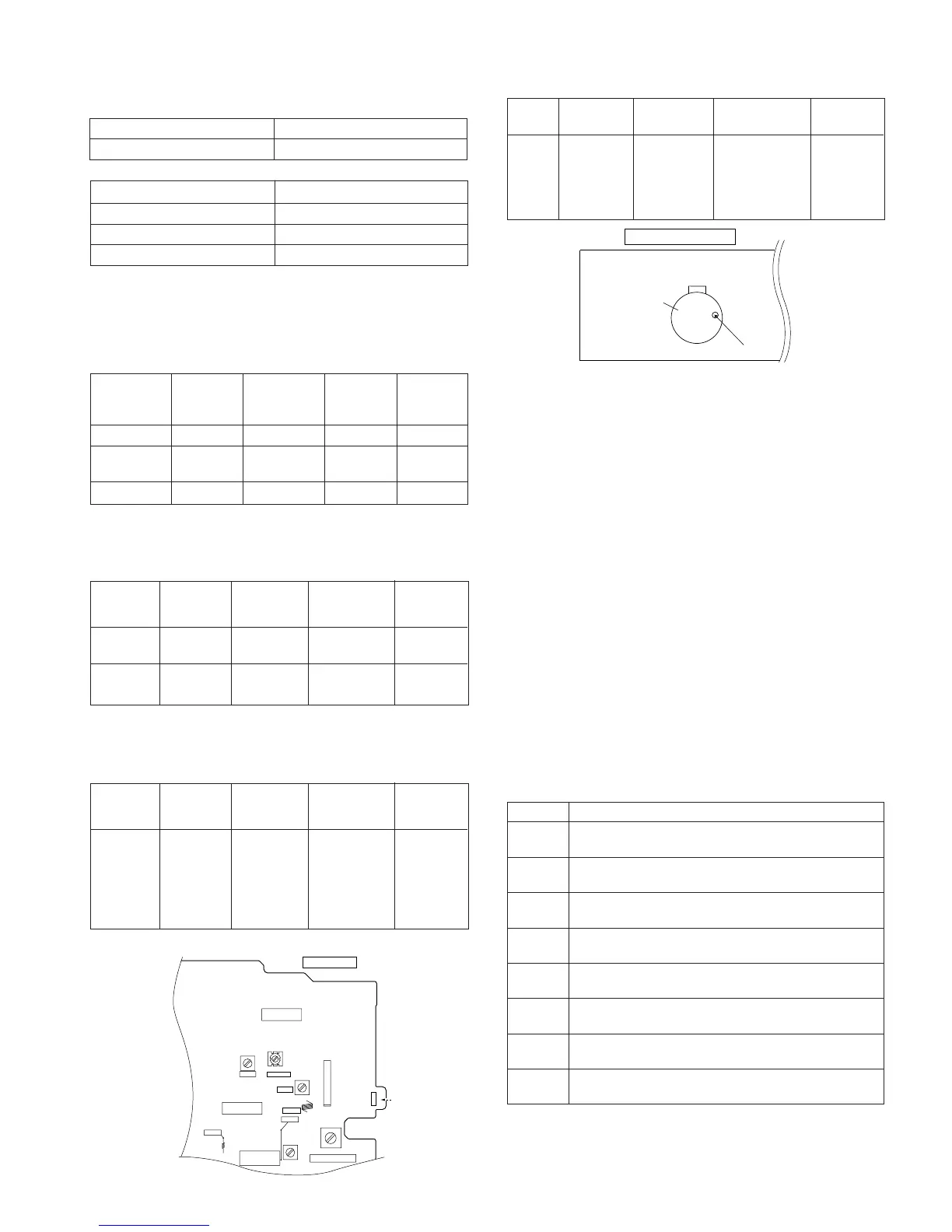

Figure 9-1

TAPE MECHANISM

Tape

Motor

Variable Resistor in motor

*1. Input: Antenna Output: TP301

*2. Input: Antenna Output: Speaker terminal

••

••

• FM RF

Signal generator: 1 kHz, 40 kHz dev., FM modulated

FM Band — 87.50 MHz T301 (fL): *1

Coverage 1.3 V ± 0.1 V

FM RF 98.00 MHz 98.00 MHz L312 *2

(10-30 dB)

Test Stage

Instrument

Connection

Frequency Frequency

Display

Setting/

Adjusting

Point

••

••

• FM IF

Signal generator: 10.7 MHz, FM modulated

IF 10.7 MHz 98 MHz T302 *1

(Turn the

core of trans-

former T302

fully counter-

clock wise)

Test Stage

Instrument

Connection

Frequency Frequency

Display

Setting/

Adjusting

Point

*1. Input: Antenna Output: TP301

Loading...

Loading...