LUBRICATION AND MAINTENANCE

45

MAINTENANCE AND INSPECTION OF

THE ROPS

NOTE: Inspect the ROPS after the first 20 hours of

operation. Following the initial inspection, the

ROPS should be checked after every 500 hours of

operation or every six months, whichever comes

first.

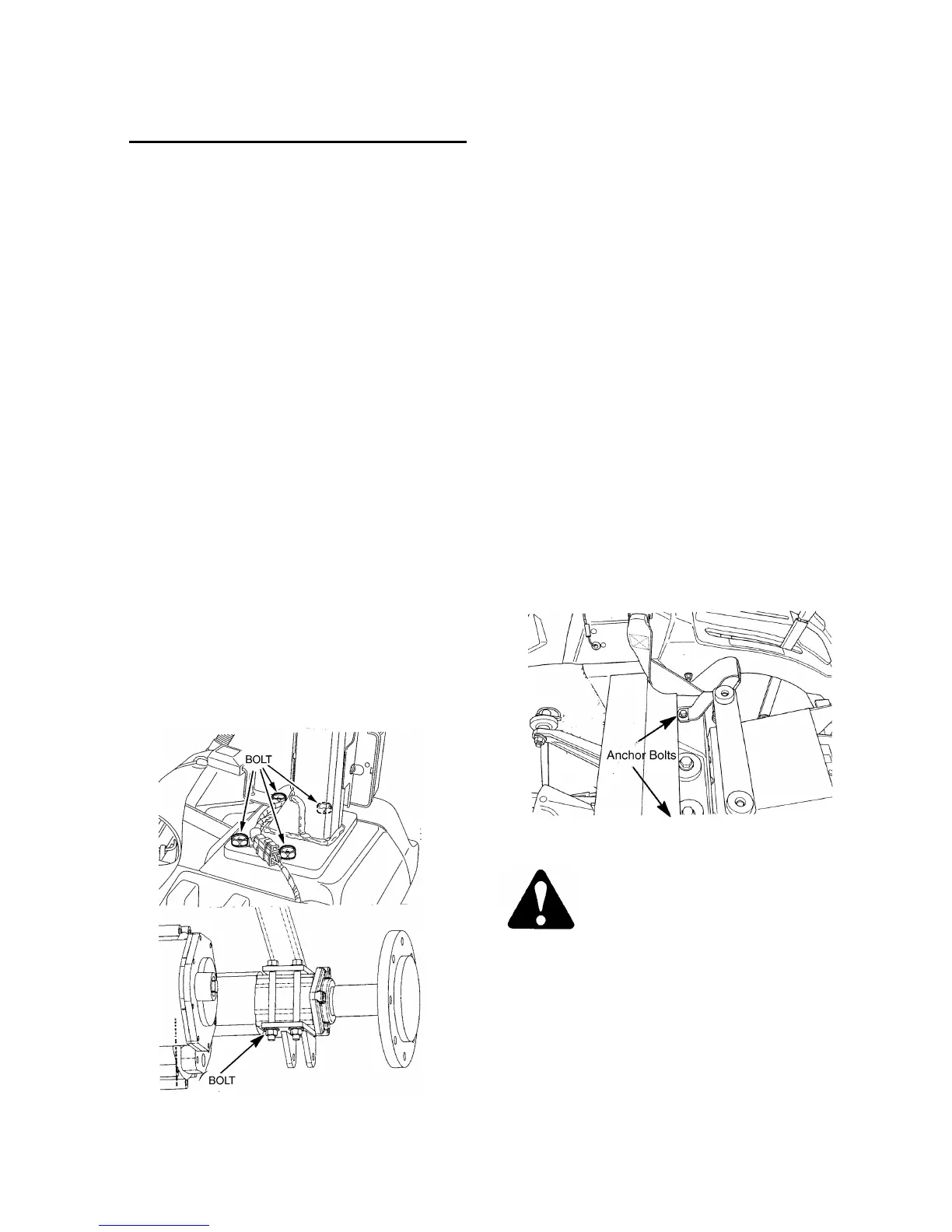

1. Check the torque of the ROPS to axle mounting

bolts, Figure 67. Tighten both front nut and bolt

assemblies to the corrected torque of 74.5 Nm

(55lbs.ft.) if necessary, with the torque being

applied to the nut. The rear bolt (not shown)

should be tightened to 166 Nm (123 ft.lbs.)

2. Also check the torque of the ROPS to fender

mounting bolts, Figure 67. Tighten the bolts to

the correct torque of 74.5 Nm (55 lbs.) if neces-

sary.

POSSIBLE DAMAGE TO THE ROPS

If the machine has rolled over or the ROPS has

been in some other type of accident (such as hit-

ting an overhead object during transport) you must

replace the ROPS to get the original protection.

Figure 67 - Mounting Bolts/ Nuts

After an accident, check for damage to (1) the

ROPS, (2) the operator’s seat, (3) the seat belt and

the seat belt mountings. Before you operate the

machine, replace all damaged parts.

IMPORTANT:

::

:Do not try to weld or straighten the

ROPS.

SEAT BELT MAINTENANCE

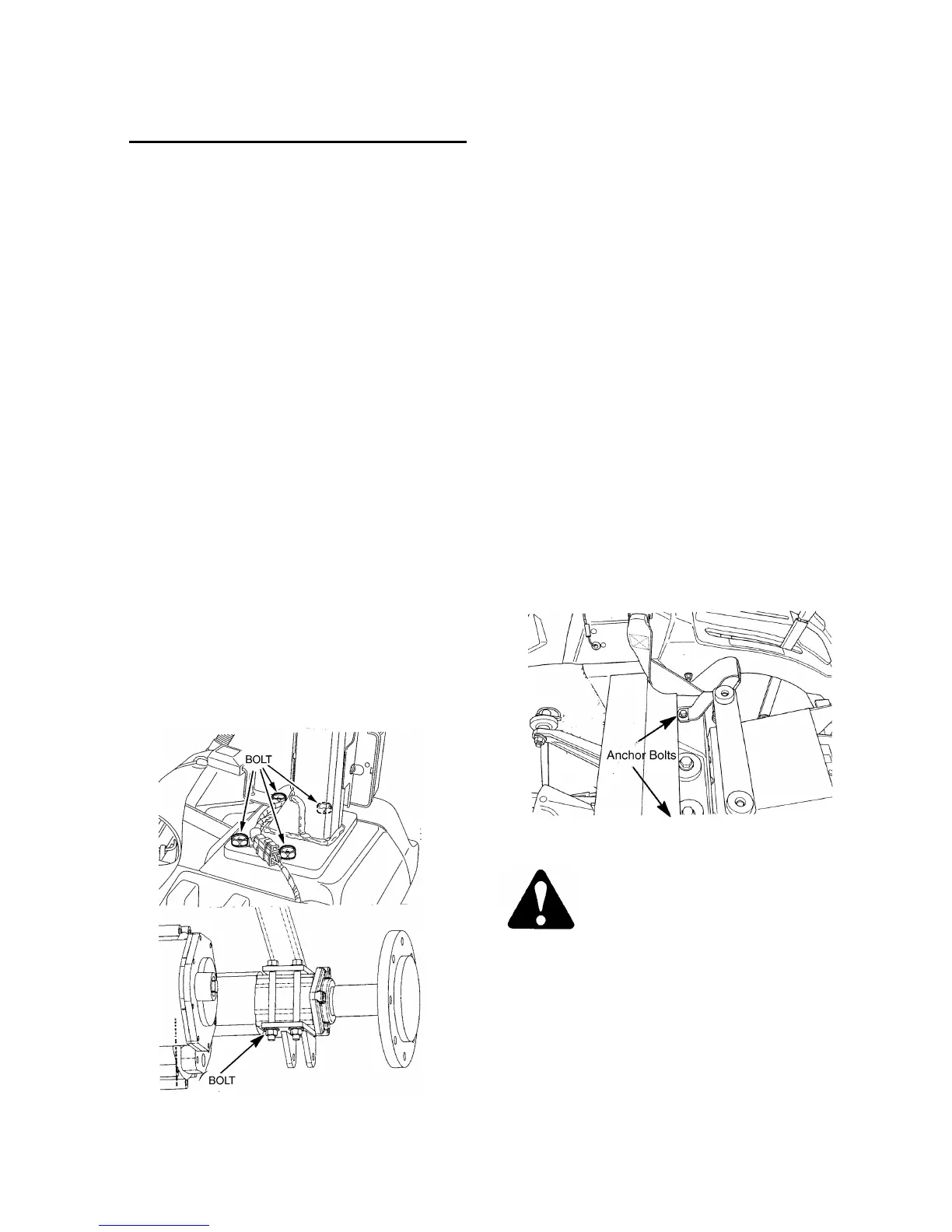

1. Inspect the operator’s seat and the mounting

parts for the seat belt. If necessary, tighten both

seat belt anchor Bolts, Figure 69 (second bolt

not visible), to the correct torque of 74.5 Nm (55

ft.lbs.) and replace parts that show wear or dam-

age.

2.

Use soap and water to clean the seat belt if

necessary

. Do not use carbon tetrachloride,

naphtha, etc., as these substances will

weaken the webbing. Additionally, do not

bleach or re-dye webbing, as these products

will also weaken the webbing.

Figure 69 - Seat Belt

WARNING:

::

:Always wear your seat belt.

Never wear the seat belt if the tractor is

not equipped with a ROPS or Safety

Cab.

FALLING OBJECT PROTECTIVE

STRUCTURE(FOPS)

When tractors are equipped with front-end Loaders

and are not equipped with safety cabs, it is rec-

ommended the tractor be equipped with a FOPS

canopy to protect the operator from falling objects.

Loading...

Loading...