Do you have a question about the Side-Power SR 100/185 T and is the answer not in the manual?

Technical drawings and measurements for the SR80/185T thruster model.

Technical drawings and measurements for the SR100/185T thruster model.

Details on motor type, gearhouse material, and propeller shaft bearings.

Information on tunnel construction, propeller type, and recommended battery capacity.

Safety features, maximum usage time, and S-link panel functions.

Guidance on selecting the best forward position for the thruster unit.

Steps for marking the hull and aligning the thruster unit longitudinally.

Instructions for measuring distances and drawing cut lines on the hull.

How to mark the outline of the thruster unit on the hull.

Instructions for cutting the hatch with a chamfer and securing it.

Steps for fitting the hatch, using wedges/shims, and ensuring a tight seal.

Guidance on moulding the thruster casing to the hull using resin and fiberglass.

Instructions for grinding and preparing surfaces for epoxy and fiberglass.

Steps for applying resin and fiberglass for secure attachment to the hull.

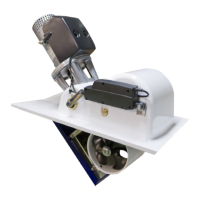

Procedures for attaching the motor to its bracket and ensuring alignment.

Important notes on painting antifouling, running the thruster out of water, and protecting the motor.

Explanation of the electrical table for battery and cable sizing.

Guidance on installing the main switch, fuse, and connecting cables.

Essential safety checks using an ohm meter for electrical isolation.

Instructions for re-tightening bolts and keeping the propeller and gearhouse clean.

Guidance on changing the zinc anode and performing seasonal checks.

Diagrams showing outside and inside measurements for the hull opening.

Instructions for aligning the template and drilling mounting holes in the hatch.

Key benefits of the S-link control system, such as waterproof connectors and NMEA 2000 compatibility.

Description of backbone cables, spur cables, power cables, and connectors.

Guidance on routing the backbone cable to minimize spur cable length and avoid interference.

Advice on handling spur cables, including leaving them unterminated and protecting connectors.

Explanation of how the S-link system receives power and connects to the backbone.

Diagrams illustrating setups with manual and automatic main switches.

Explanation of panel buttons, status LEDs, and basic operation.

Detailed breakdown of LED codes, associated failures, and recommended user actions.

Checklist items for ensuring correct propeller, motor, and electrical connections.

Items for installer/yard to verify, including compartment isolation and running voltage.

Precautions regarding the main battery switch, avoiding accidental starts, and control device usage.

Information on maximum usage time, operating in water vs. air, and environmental factors.

Advice on maintaining thruster performance through proper battery care and voltage.

Solutions for issues where the motor runs but no thrust is generated.

Steps to diagnose and fix issues with starting or directional control.

Troubleshooting for reduced performance, solenoid flapping, and lock-in problems.

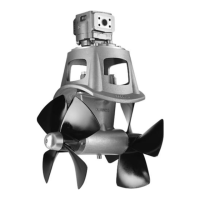

Identification of parts for the SR80/185T model with part numbers.

Identification of parts for the SR100/185T model with part numbers.

| Brand | Side-Power |

|---|---|

| Model | SR 100/185 T |

| Category | Outboard Motor |

| Language | English |

Loading...

Loading...