3ZX1012-0RB22-1CA1 5

2.3 Sensor circuit wiring

2.4 Sensor circuit short-circuit detection

This corresponds to the following typical cable lengths:

2.5 Short-circuit protection according to EN 60947-4-1 for

utilization category 2

The short-circuit protection must be adopted from the separate over-

current protection devices.

2.6 Cable protection

2.7 Automatic RESET

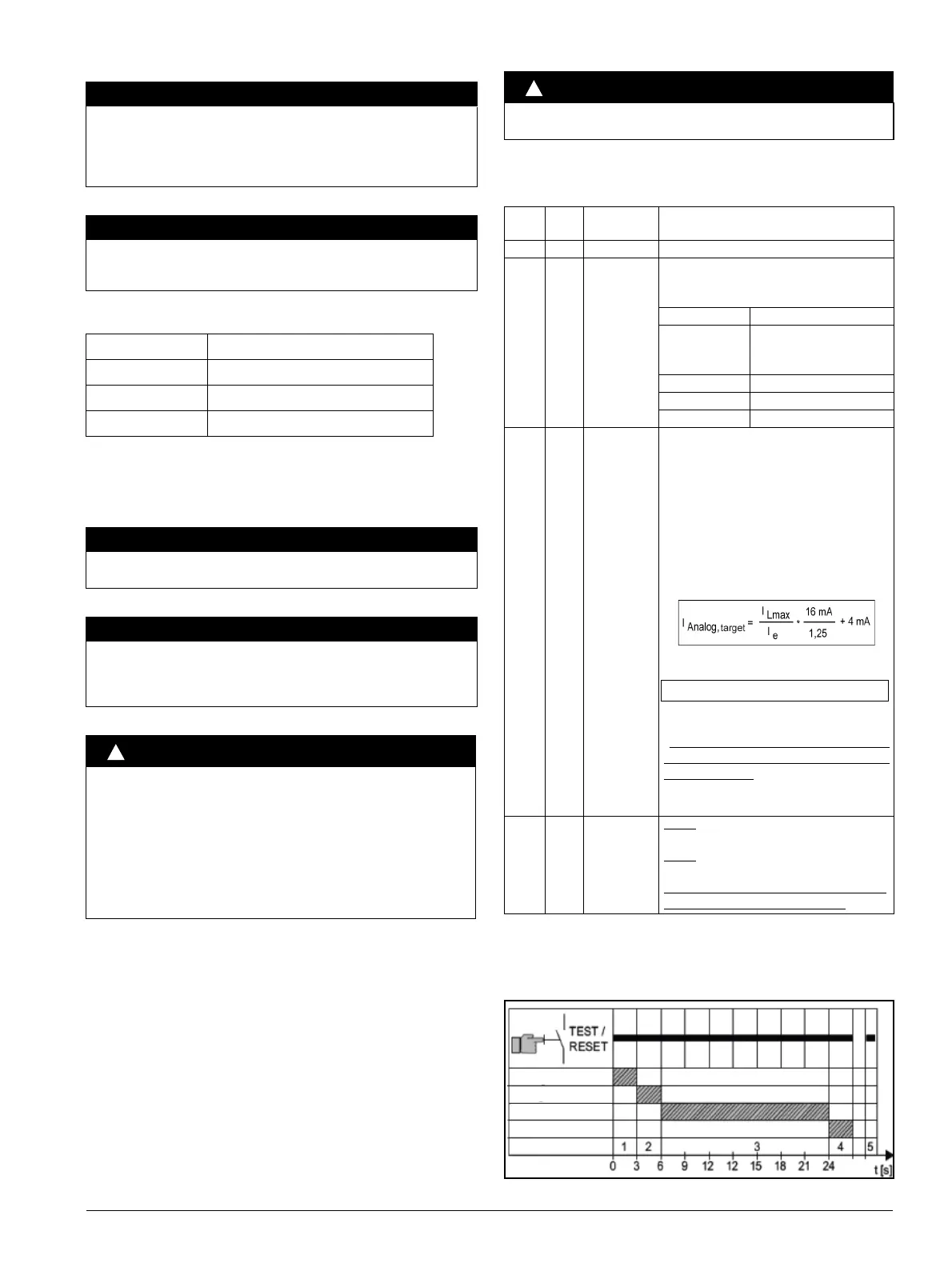

2.8 User test

The tests according to EN 60079-17 can be carried out together with

the user test. This test includes a complete functional test. All four test

phases must be carried out as described in the following table. The

individual test phases include the LED test (1), the configuration test

(2), the internal test with current measurement (3) and the relay test

(4). The measured current values must be checked!

The measured current values and the correct opening and closing of

the relay contacts (test phase 4) must be checked!

All protective functions remain activated during the test. A tripping

operation or a warning results in abortion of the test!

To start the test, press the TEST / RESET button for t > 1 s.

*) When the three red LEDs flicker, relay switch-off has been initiated.

Up to this point in time, it is possible to abort the user test without

switching off the relays.

The following graphic shows an overview of the temporal course:

NOTICE

The lines in the measuring circuit must be laid as separate control

lines. The use of motor feeder lines or other main power lines is

not permissible. Shielded control cables must be used if extreme

inductive or capacitive interferences from high tension cables run-

ning in parallel are to be expected.

NOTICE

To ensure reliable functioning of the short-circuit protection, the

line resistance in the thermistor circuit (when the thermistor is

short-circuited) must not exceed 10 Ω!

Cable cross section Cable lengths at the thermistor input

2,5 mm

2

2x250m

1,5 mm

2

2x150m

0,5 mm

2

2x50m

NOTICE

In combination with other contactors please observe the respec-

tive maximum contactor protection for utilization class 2.

NOTICE

Excessive surface temperatures of the cables and lines must be

prevented by dimensioning the cross sections accordingly.

An adequate cable cross section must be chosen for heavy start-

ing - CLASS20 and CLASS30 - in particular.

CAUTION

When the 3RB22 / 3RB24 is in the "Automatic RESET" mode, the

reset is carried out automatically at the end of the cooling time

without the RESET button being pressed. In this case, an addi-

tional ON button is necessary to prevent the motor from automati-

cally starting up again after being tripped. If, in this case, the

3RB22 / 3RB24 is used without thermistor protection, the motor

can only be connected by a specialist.

The "Automatic RESET" mode may not be used in applications in

which an unexpected motor restart could lead to personal injury or

damage to property.

CAUTION

This test must be carried out by a specialist familiar with the stan-

dards stated!

Test

phase

Durati

on

Description Comment

1 3 s LED test The user checks whether all LEDs are flashing

2 3 s Configuration

test

Flickering LEDs indicate that the respective

functions are activated. The user checks the

active functions

LED Function

3RB22: READY

3RV24: Device/

IO-Link

Automatic reset active

GND-Fault Ground fault evaluation

THERMISTOR Thermistor activated

OVL Overload warning active

3 18 s Internal test The system is executing internal tests. The

analog output is permanently activated

throughout the test period. The user must

compare the maximum motor current of the 3

phases with the current at the analog output.

The following must apply:

• the effective current must be between 30% and

125% of the nominal current

• the maximum motor current leads to an “ideal”

analog current I

Analog,target

of

• the actual measured analog current

I

Analog, actual

must be within the range

0.9 * I

Analog,target

≤ I

Analog,actual

≤ 1.1 *

I

Analog,target

• Correct functioning cannot be guaranteed

if the measured current does not fall within

these tolerances.

The LEDs show the running time (see the

following graphic).

4 Relay test

*)

3RB22

: The system must switch off outputs 95 /

96 and 05 / 06.

3RB24

: The system must switch off outputs 95 /

96 and 95/ 98.

Correct functioning cannot be guaranteed

if the output contacts do not open!

Loading...

Loading...