Start-Up 09.02

4-62 Siemens AG 6SE7087-6AK85-1AA0

Rectifier/Regenerating Unit Operating Instructions

Functionality according to layer 2

The user data from the user software (as COBs on byte level) must be transferred directly to layer 2 (see also

the examples of PZD and PKW data exchange given further down).

Functionality according to layer 7 (CANopen)

CANopen is not supported by the SIMOVERT 6SE70 rectifier unit.

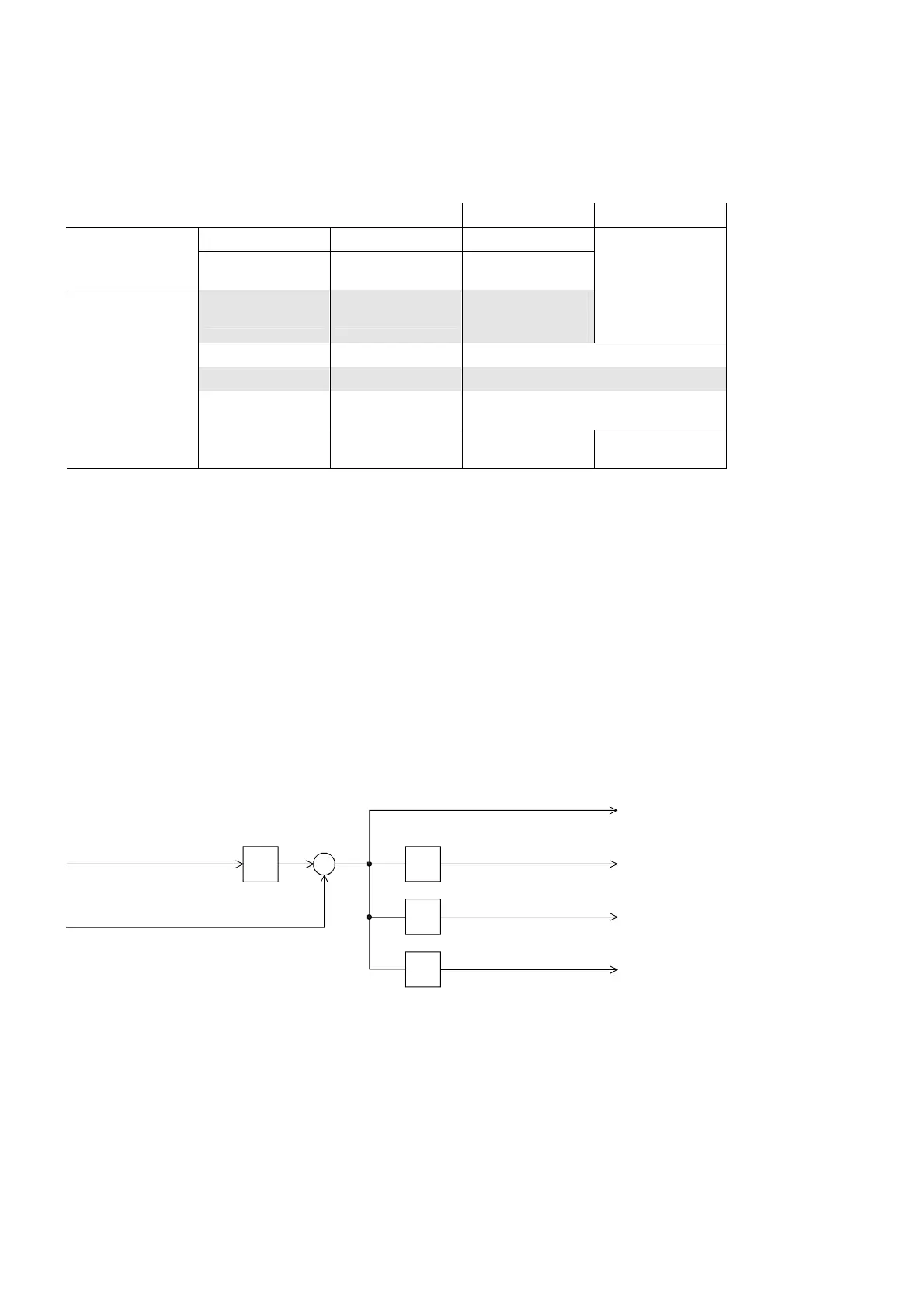

CAN protocol Device Net

Device profile

Application

Communication

profile

CIA

DS 301

Layer 7 Application layer

CIA CAL

DS 201 .. 205, 207

CAL

Device net

specification includes:

- Device profile

– Communication

profile

– Application layer

Layer 3-6

Layer 2 Data link layer ISO-DIS 11898

Physical layer,

electrical

Communication

Layer 1

Physical layer,

mechanical

CIA DS 102-1 Device Net ODVA

4.5.3.1 Description of CBC with CAN Layer 2

User data are exchanged between the CAN master and the CAN boards on the drives, i.e. the slaves. User

data are categorized as either process data (control and status information, setpoints and actual values) or data

which relate to parameters.

Process data (

PZDs) are time-critical and therefore processed faster by the drive (every 3.3 ms at system

frequency of 50 Hz) than the non-time-critical

PKW data (parameter identifier value), which is processed by the

drive every 20 ms.

All settings required to operate the communication board are made in drive parameters.

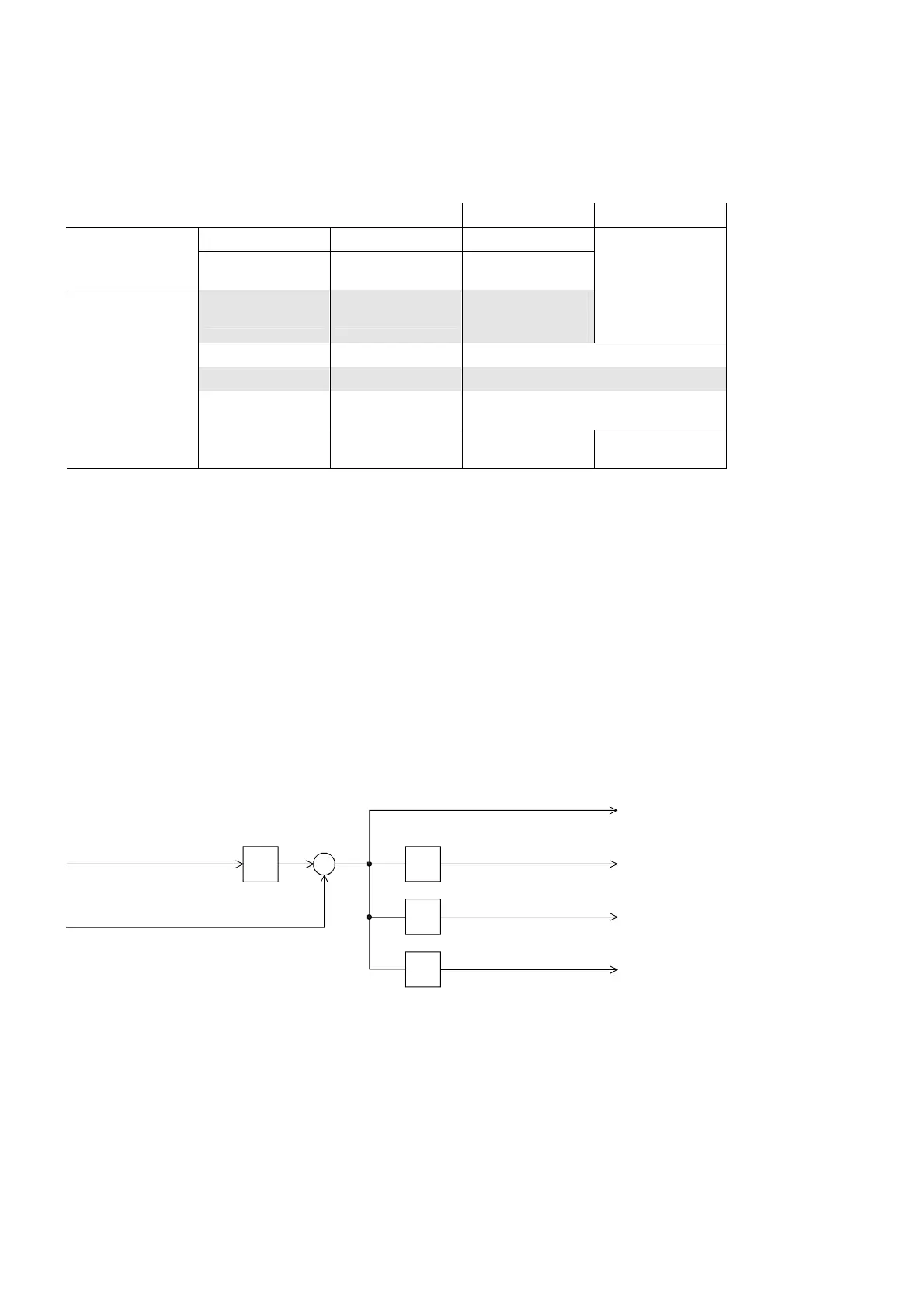

Process data (PZD) are categorized as either data received by the drive (control words and setpoints:

PZD

Receive

) or data transmitted by the drive (status words and actual values: PZD Send). A maximum of 16 PZDs

can be transferred in either direction; these are divided into COBs with 4 data words each by the

communication board. In other words, 4 COBs are required to transfer 4 PZD words, with each COB requiring

its own separate identifier. Identifiers are assigned in the CB parameters as shown in the following diagram:

x4

+

+1

+2

+3

Node address

of drive (P918)

Basic identifier for parameterizing

PZD Receive (U712)

PZD Receive 1 (setpoints 1 to 4)

PZD Receive 2 (setpoints 5 to 8)

PZD Receive 3 (setpoints 9 to 12)

PZD Receive 4 (setpoints 13 to 16)

Example of PZD Receive:

P918 = 1 This settings assigns identifier 100 to the first 4 receive PZDs,

P697 = 96 identifier 101 to the second 4 receive PZDs, etc.

AoteWell Automation Sales Team

Buy Siemens PLC HMI Drives at AoteWell.com

Loading...

Loading...