Commissioning

4.3 Connecting the inverter to the fieldbus

CU240B-2 and CU240E-2 Control Units

Compact Operating Instructions, 04/2015, A5E35792002B AA

27

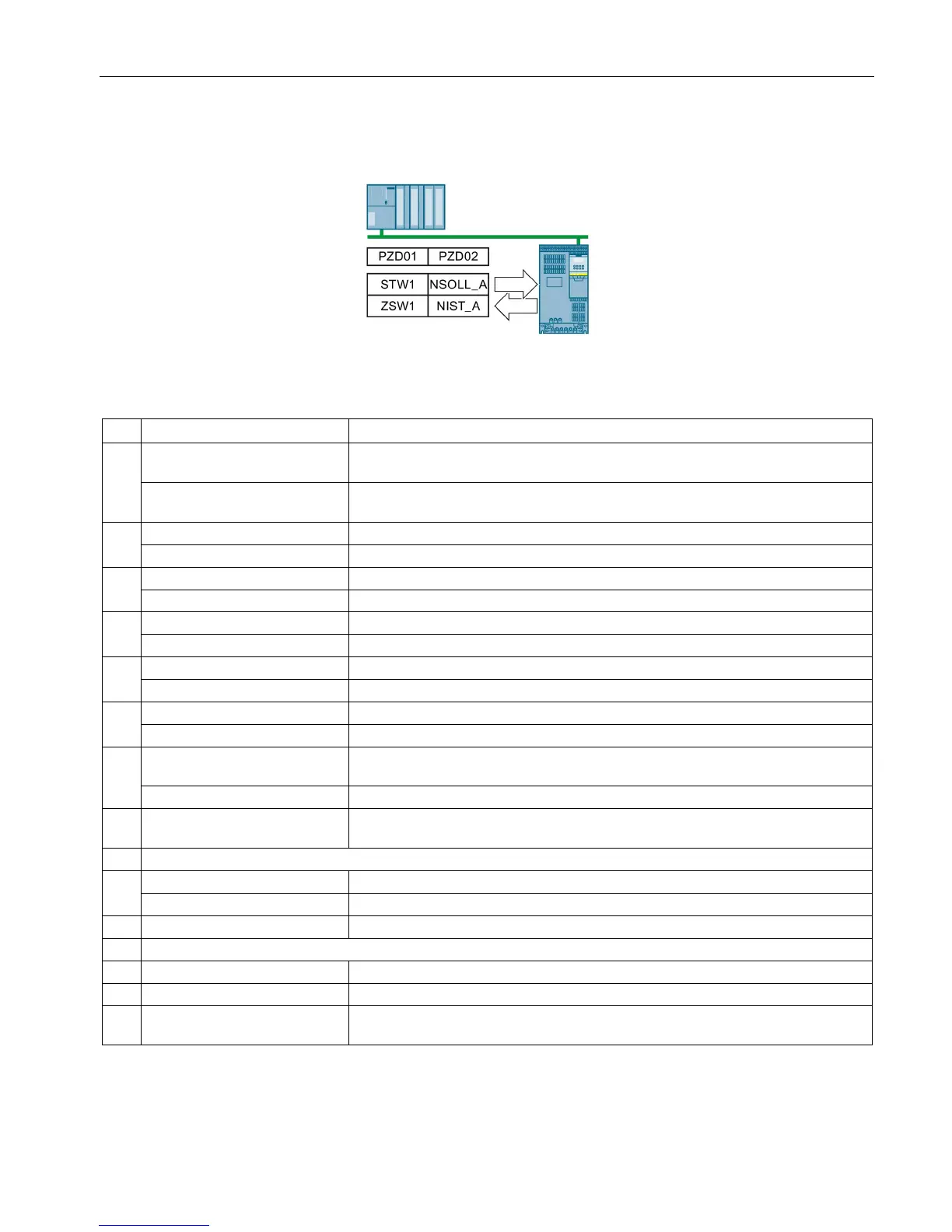

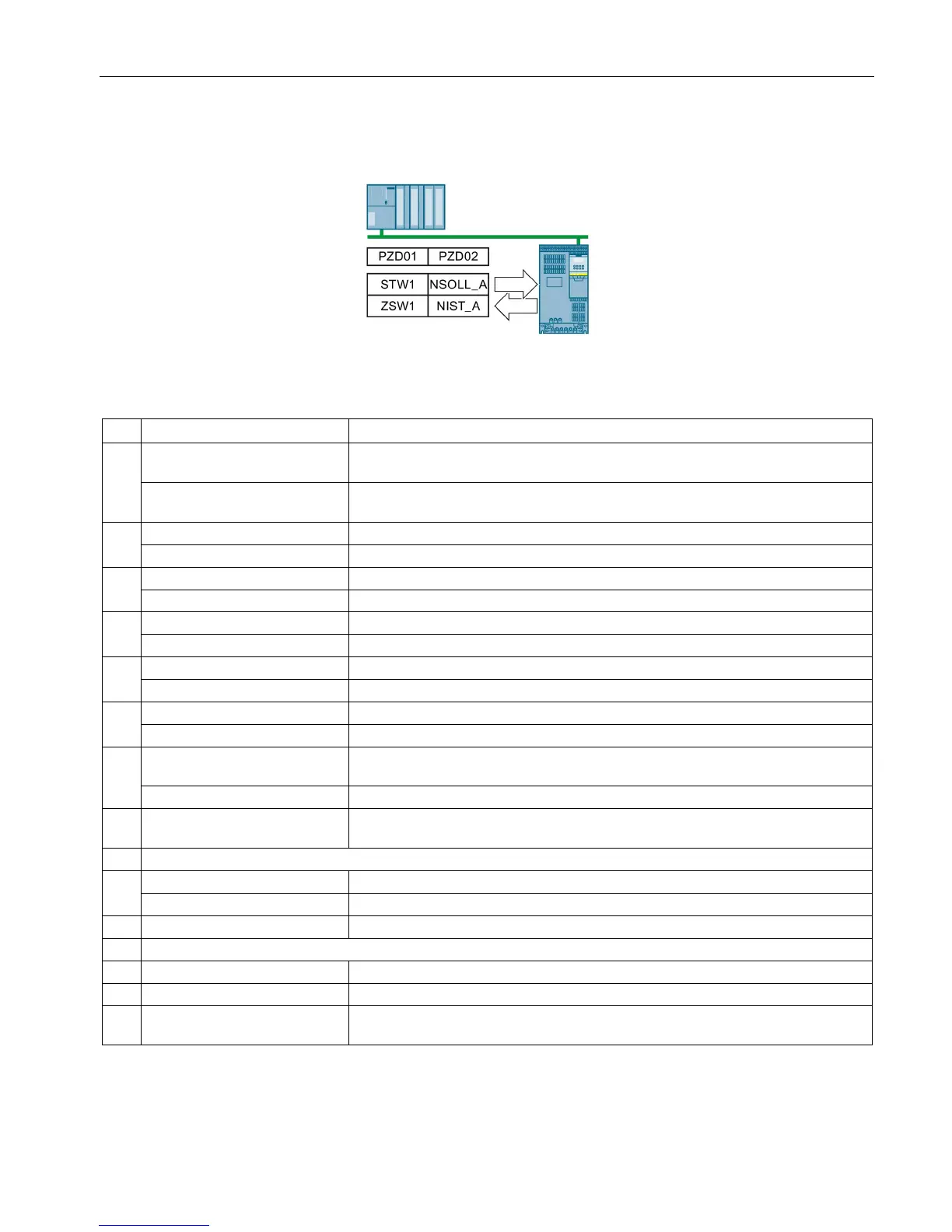

Examples for telegrams via PROFIBUS and PROFINET

Control word 1 (STW1), PZD receive word 1 (word: r2050[0], bits: r2090.00 … r2090.15)

0 0 = OFF1 The motor brakes with the ramp-down time p1121 of the ramp-function generator.

The inverter switches off the motor at standstill.

0 → 1 = ON The inverter goes into the "ready" state. If, in addition bit 3 = 1, then the inverter

Switch off the motor immediately, the motor then coasts down to a standstill.

Precondition in order to be able to switch on the motor using bit 0 (ON command).

The motor brakes with the OFF3 ramp-down time p1135 down to standstill.

Precondition in order to be able to switch on the motor using bit 0 (ON command).

Switch off the motor immediately → motor coasts down to a standstill.

Precondition in order to be able to switch on the motor using bit 0 (ON command).

The inverter immediately sets its ramp-function generator output to 0.

The ramp-function generator can be enabled.

The output of the ramp-function generator stops at the actual value.

The output of the ramp-function generator follows the setpoint.

6 0 = Inhibit setpoint The inverter brakes the motor with the ramp-down time p1121 of the ramp-function

1 = Enable setpoint Motor accelerates with the ramp-up time p1120 to the setpoint.

7 0 → 1 = Acknowledge faults Acknowledge fault. If the ON command is still active (bit 0 = 1), the inverter

switches to "closing lockout" state.

The inverter ignores the process data from the fieldbus.

Control via fieldbus, the inverter accepts the process data from the fieldbus.

Invert setpoint in the inverter.

Increase the setpoint saved in the motorized potentiometer.

Reduce the setpoint saved in the motorized potentiometer.

15 Reserved Changes over between settings for different operation interfaces (command data

Loading...

Loading...