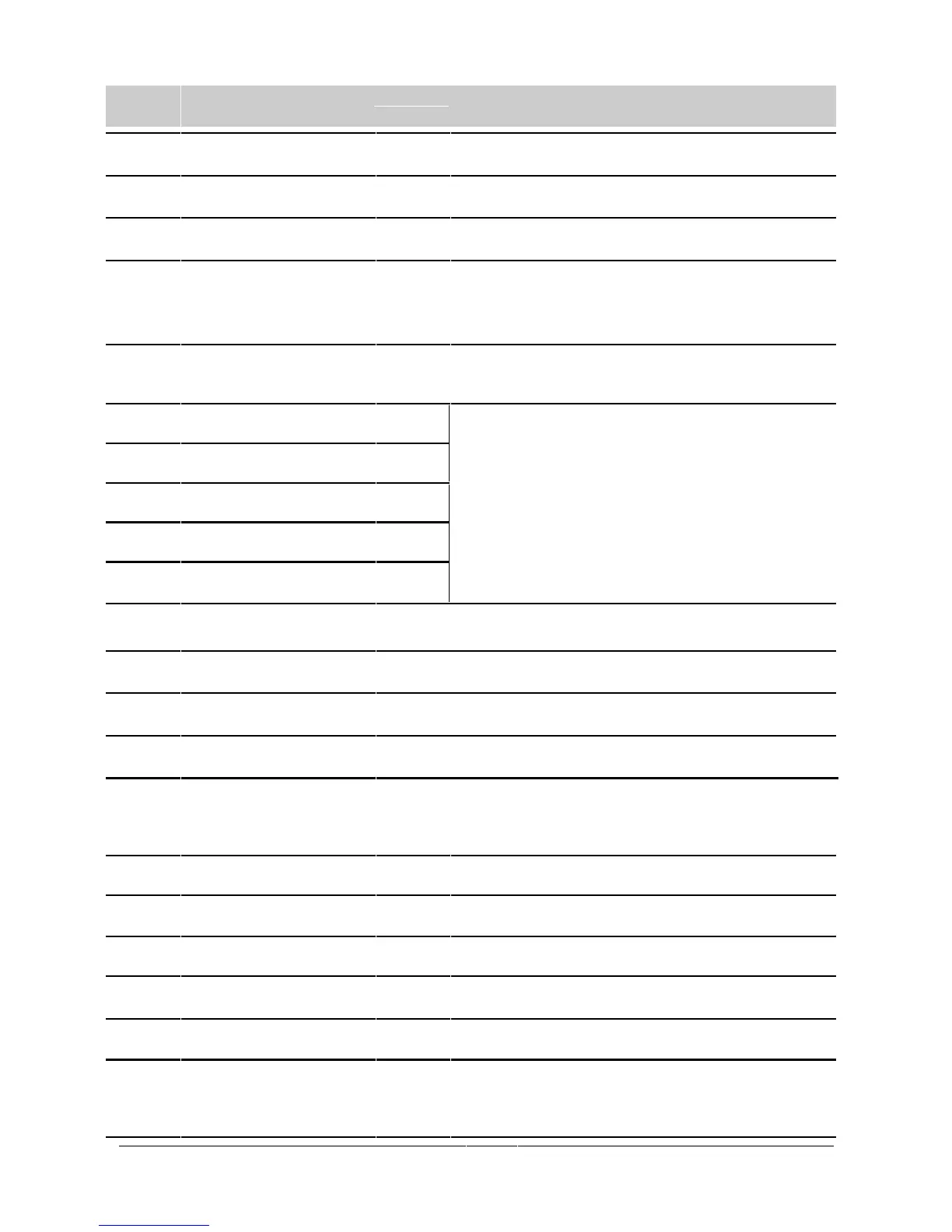

P121

Enable/disable RUN button 0 - 1

[1]

0 = RUN button disabled.

1 = RUN button enabled (only possible if P007 = 1).

P122

Enable/disable

FORWARD/REVERSE button

0 - 1

[1]

0 = FORWARD/REVERSE button disabled.

1 = FORWARD/REVERSE button enabled (only possible if P007 = 1).

P123

Enable/disable JOG button 0 - 1

[1]

0 = JOG button disabled.

1 = JOG button enabled (only possible if P007 = 1).

P124

Enable/disable ∆ and ∇ buttons

0 - 1

[1]

0 = ∆ and ∇ buttons disabled.

1 = ∆ and ∇ buttons enabled (only possible if P007 = 1).

Note: This applies for frequency adjustment only. The buttons can

still be used to change parameter values.

P125

Reverse direction inhibit 0 - 1

[1]

0 = Reverse direction disabled. Inhibits reverse commands from ALL

sources (reverse RUN commands result in forward rotation)

1 = Normal operation (FORWARD/REVERSE operation allowed)

P131

Frequency setpoint (Hz) 0.00-400.00

[-]

P132

Motor current (A) 0.0 - 99.9

[-]

P134

DC link voltage (V) 0 - 1000

[-]

P135

Motor RPM 0 - 9999

[-]

P137

Output voltage (V) 0 - 1000

[-]

P140

Most recent fault code 0 - 9999

[-]

The last recorded fault code (see section 6) is stored in this parameter.

This is a copy of the code stored in P930.

P141

Most recent fault code -1 0 - 9999

[-]

This parameter stores the last recorded fault code prior to that stored

in P140/P930.

P142

Most recent fault code -2 0 - 9999

[-]

This parameter stores the last recorded fault code prior to that stored

in P141.

P143

Most recent fault code -3 0 - 9999

[-]

This parameter stores the last recorded fault code prior to that stored

in P142.

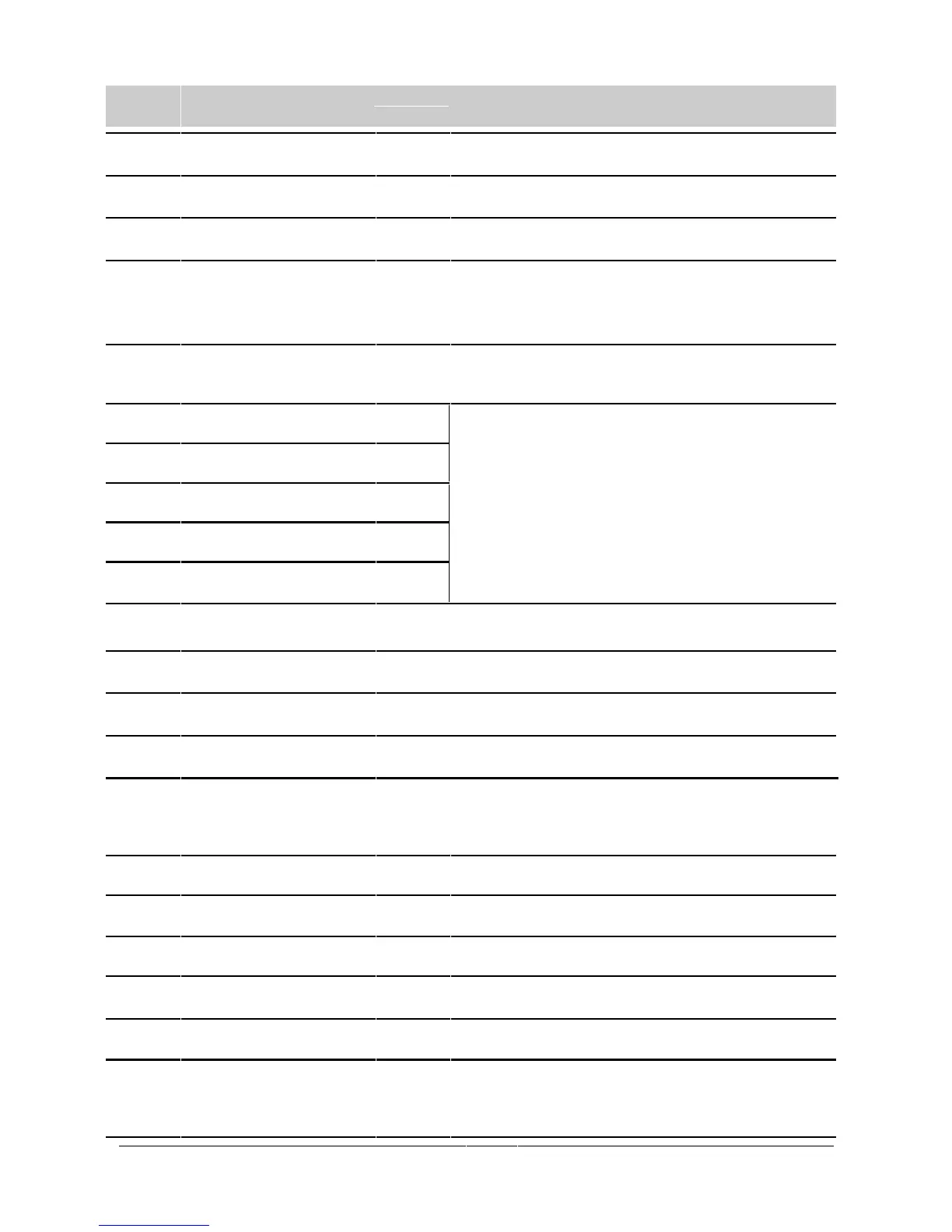

P201

Closed loop mode 0 - 2

[0]

0 = Normal operation (closed loop control disabled).

1 = Not used.

2 = Closed loop control using analogue input for transducer feedback

input.

P202 •

P gain (%) 0.0 - 999.9

[1.0]

Proportional gain.

P203 •

I gain (%) 0.00 - 99.99

[0.00]

Integral gain.

0.01% corresponds to the longest integral action time.

P205 •

Sample interval (x 25 ms) 1 - 2400

[1]

Sampling interval of feedback sensor.

P206 •

Transducer filtering 0 - 255

[0]

0 = Filter off.

1 - 255 = Low pass filtering applied to sensor.

P207 •

Integral capture range (%) 0 - 100

[100]

Percentage error above which integral term is reset to zero.

P208

Transducer type 0 - 1

[0]

0 = An increase in motor speed causes an increase in sensor

voltage/current output.

1 = An increase in motor speed causes a decrease in sensor

voltage/current output.

Read-only parameters. These are copies of the values stored in

P001 but can be accessed directly via the serial link.

Loading...

Loading...