English 9. SUPPLEMENTARY INFORMATION

G85139-H1751-U529-D1 © Siemens plc 199

4/8/99

72

9. SUPPLEMENTARY INFORMATION

9.1 Application Example

Set-up procedure for a simple application

Motor: 230 V

1.5 kW output power

Application requirements: Setpoint adjustable via potentiometer 0 - 50 Hz

Ramp-up from 0 to 50 Hz in 15 seconds

Ramp-down from 50 to 0 Hz in 20 seconds

Inverter used: MMV150 (6SE3216-8BB40)

Settings: P009 = 2 (all parameters can be altered)

P080 - P085 = values given on motor rating plate

P006 = 1 (analogue input)

P002 = 15 (Ramp-up time)

P003 = 20 (Ramp-down time)

This application is now to be modified as follows:

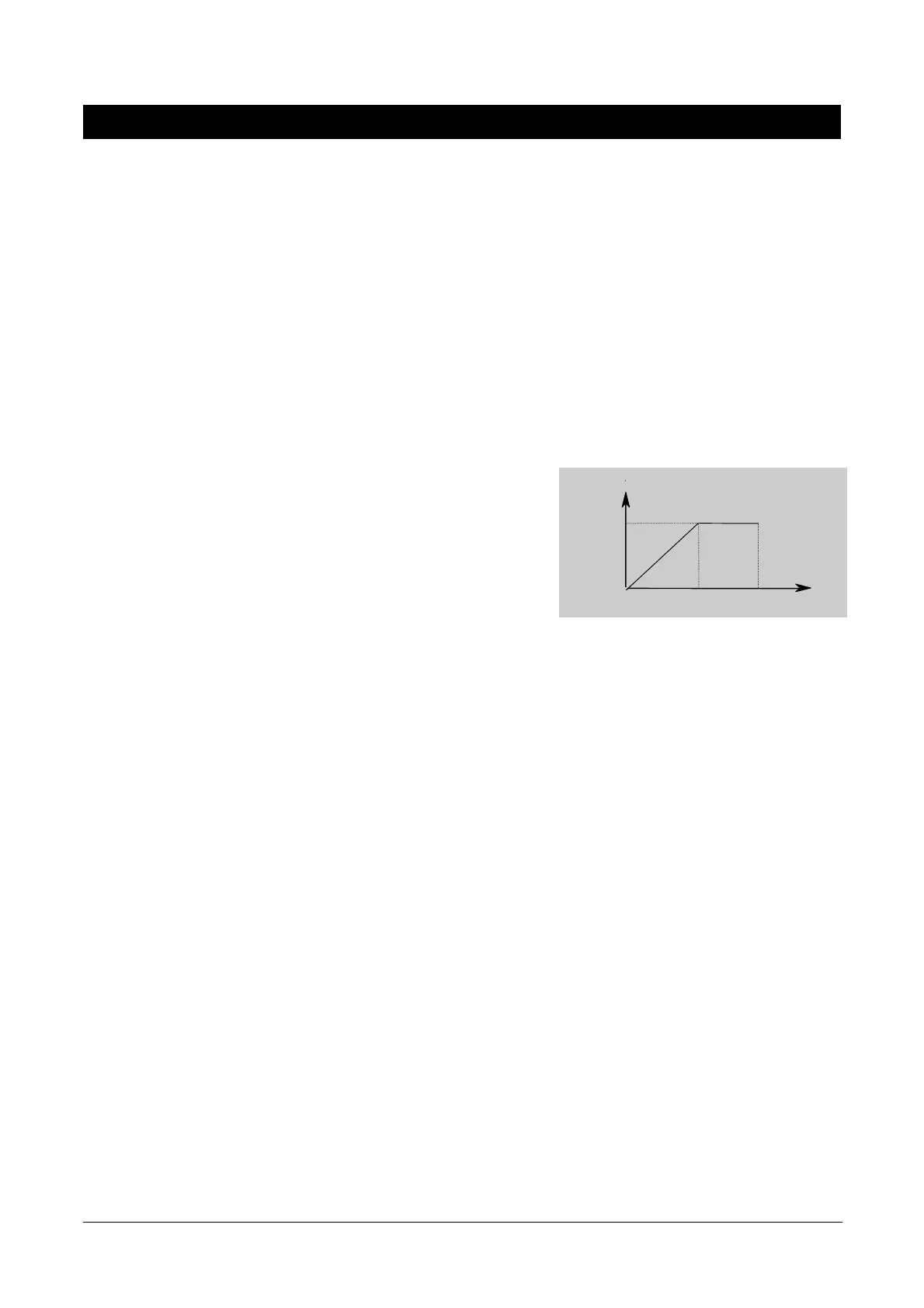

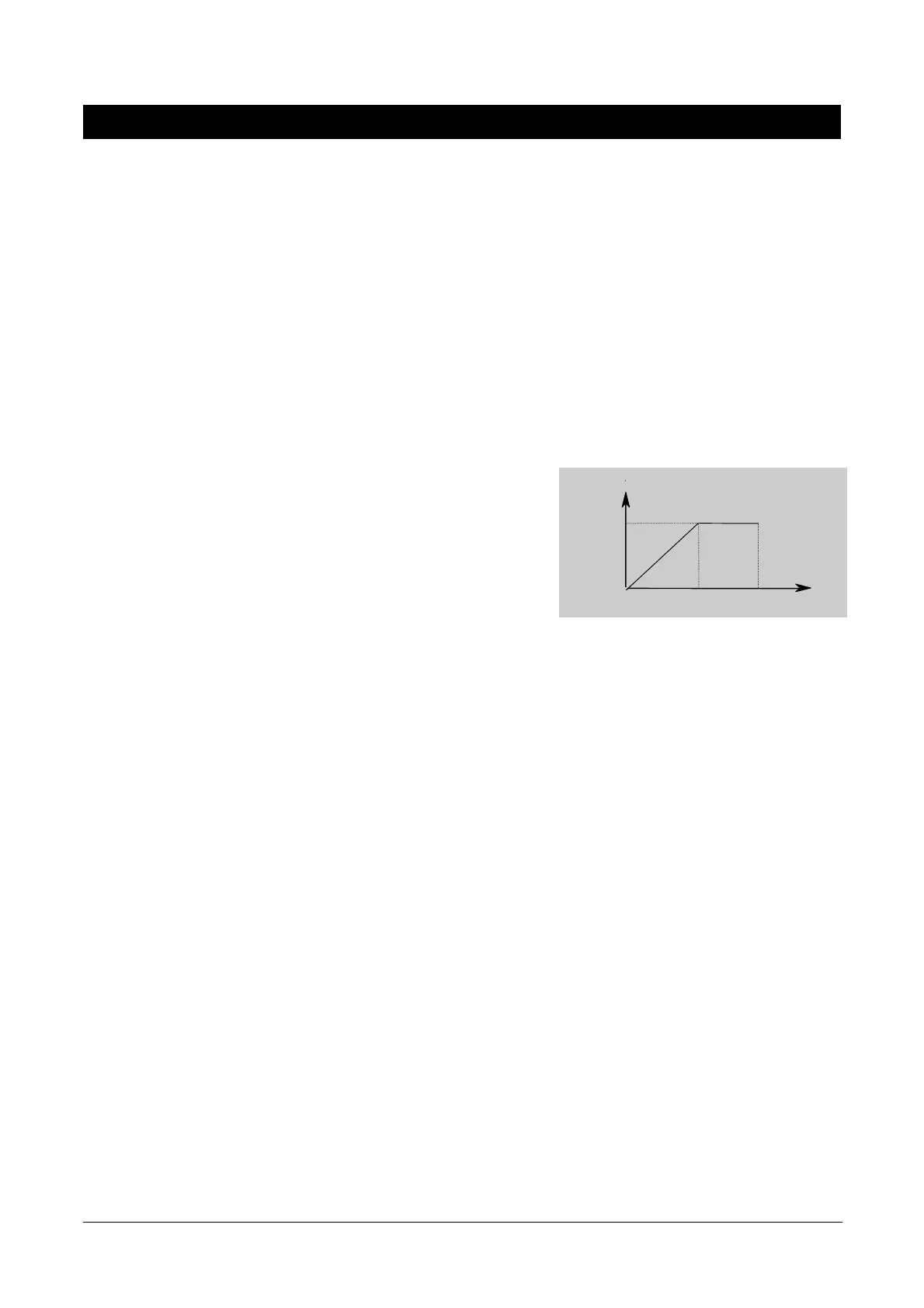

Operation of motor up to 75 Hz

(voltage/frequency curve is linear up to 50 Hz).

Motor potentiometer setpoint in addition to

analogue setpoint .

Use of analogue setpoint at maximum 10 Hz.

Settings: P009 = 2 (all parameters can be altered)

P013 = 75 (maximum motor frequency in Hz)

P006 = 2 (setpoint via motor potentiometer or fixed setpoint)

P024 = 1 (analogue setpoint is added)

P022 = 10 (maximum analogue setpoint at 10 V = 10 Hz)

9.2 USS Status Codes

The following list gives the meaning of status codes displayed on the front panel of the inverter when the serial link is in use and

parameter P001 is set to 006:

001 Message OK

002 Slave address received

100 Invalid start character

101 Time-out

102 Checksum error

103 Incorrect message length

104 Parity fail

Notes

(1) The display flashes whenever a byte is received, thus giving a basic indication that a serial link connection is established.

(2) If ‘100’ flashes on the display continuously, this usually indicates a bus termination fault.

V

f (Hz)

220

50

75

Loading...

Loading...