Connecting up

5.7 Functional ground

SCALANCE XR-300WG

46 Operating Instructions, 05/2017, C79000-G8976-C454-01

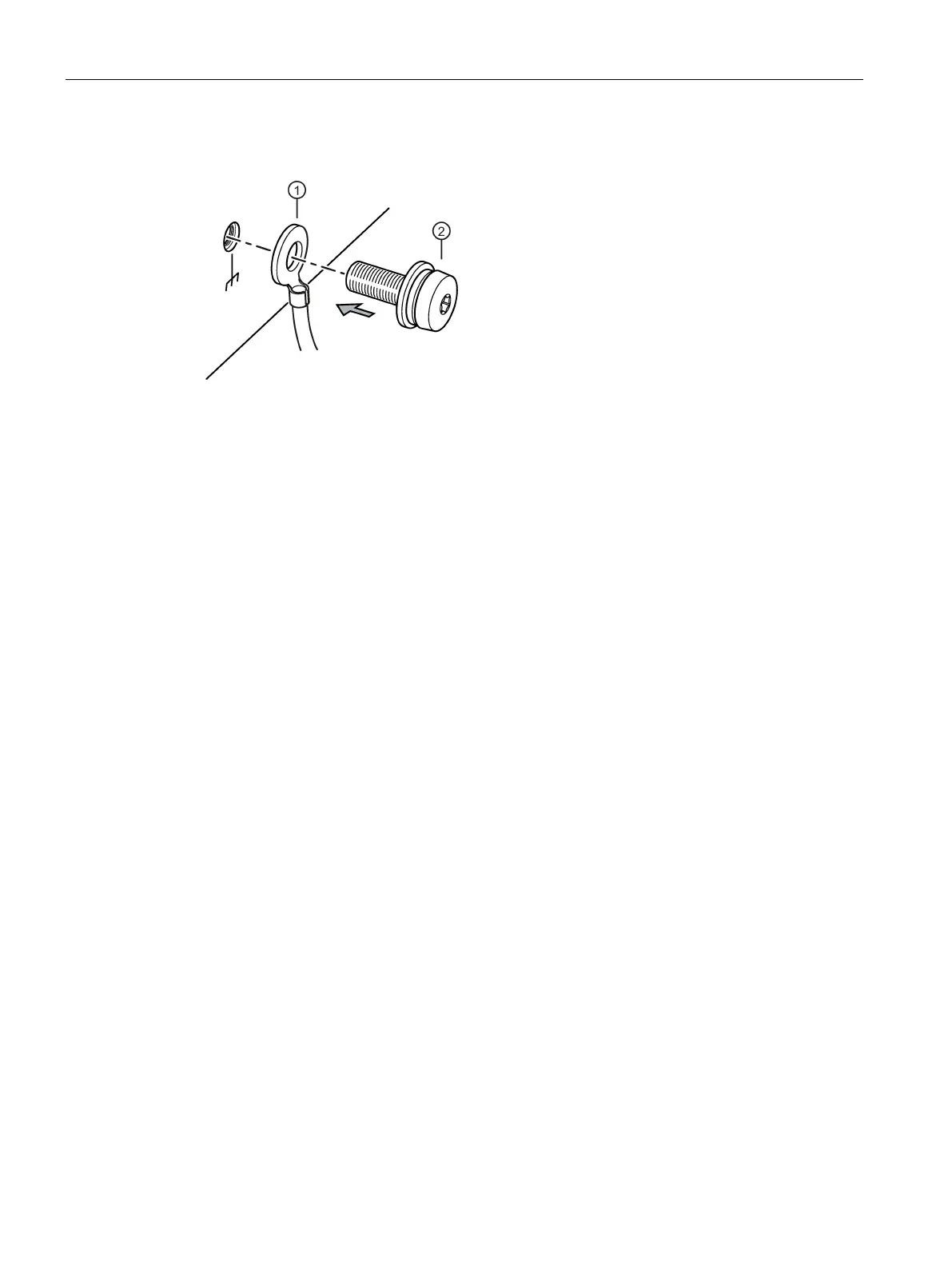

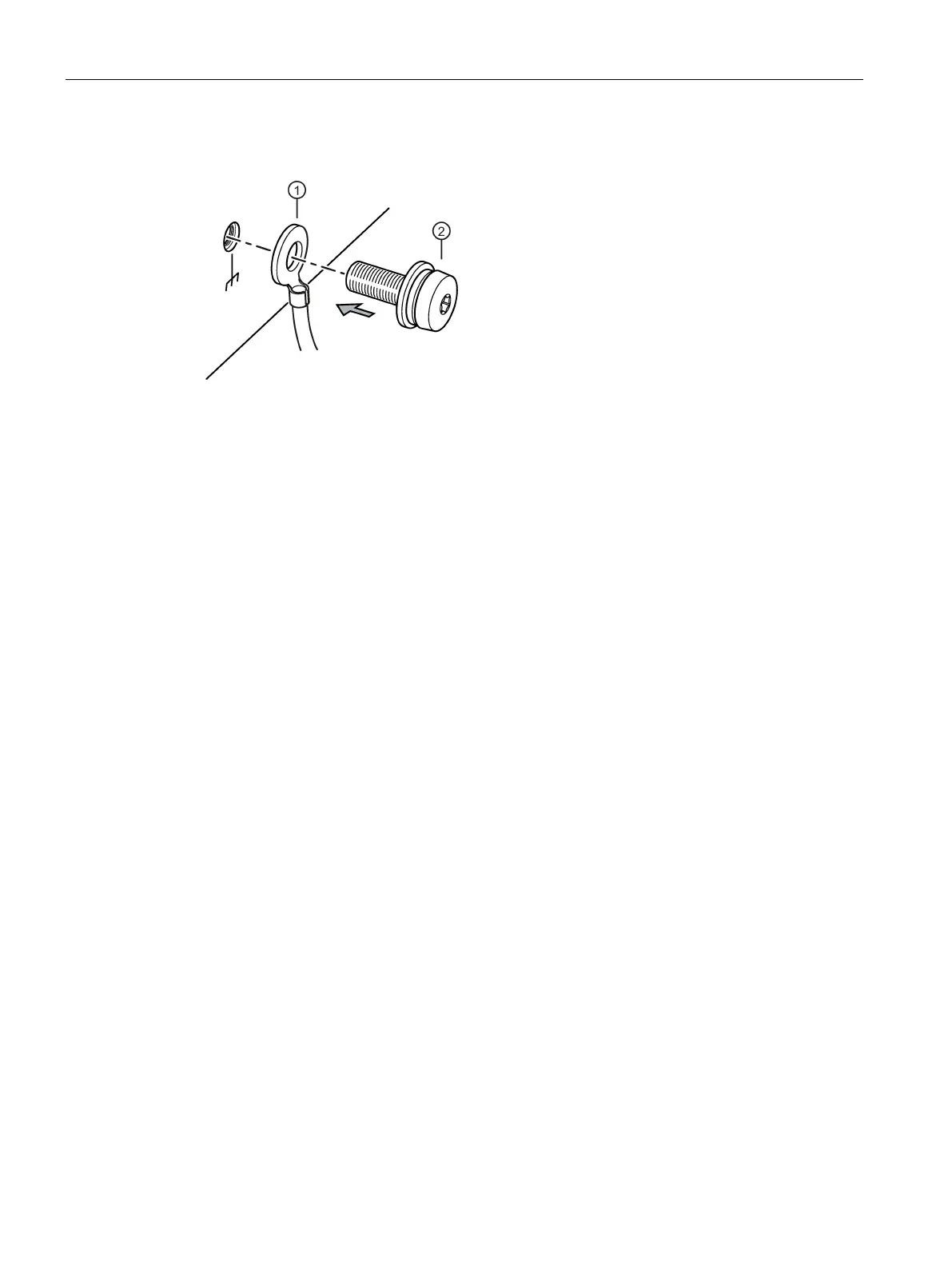

Connecting up functional ground

Grounding terminal with cable

Grounding screw with spring washer and washer

To connect the functional ground, use a copper cable of category 20 AWG or a cable with a

cross-section ≥ 0.75 mm

2

.

Follow the steps below to connect the functional ground:

1. Loosen the grounding screw.

2. Put the grounding terminal

①, and the grounding screw ② together as shown in the

drawing.

3. Tighten the grounding screw

② with a maximum tightening torque of 1.5 Nm.

Protective earth/functional ground

The connection of the reference potential surface with the protective earth system is

normally in the cabinet close to the power feed-in. This earth conducts fault currents to

ground safely and according to DIN/VDE 0100 is a protective earth to protect people,

animals and property from too high contact voltages.

Apart from the protective earth, there is functional grounding in the cabinet. According to

EN60204-1 (DIN/VDE 0113 T1) electrical circuits must be grounded. The chassis (0 V) is

grounded at one defined point. Here, once again the grounding is implemented with the

lowest leakage resistance to ground in the vicinity of the power feed-in.

With automation components, functional ground also ensures interference-free operation of

a controller. Via the functional ground, interference currents coupled in via the connecting

cables are discharged to ground.

Loading...

Loading...