SED2 VFD Electronic Bypass Option Operating Instructions

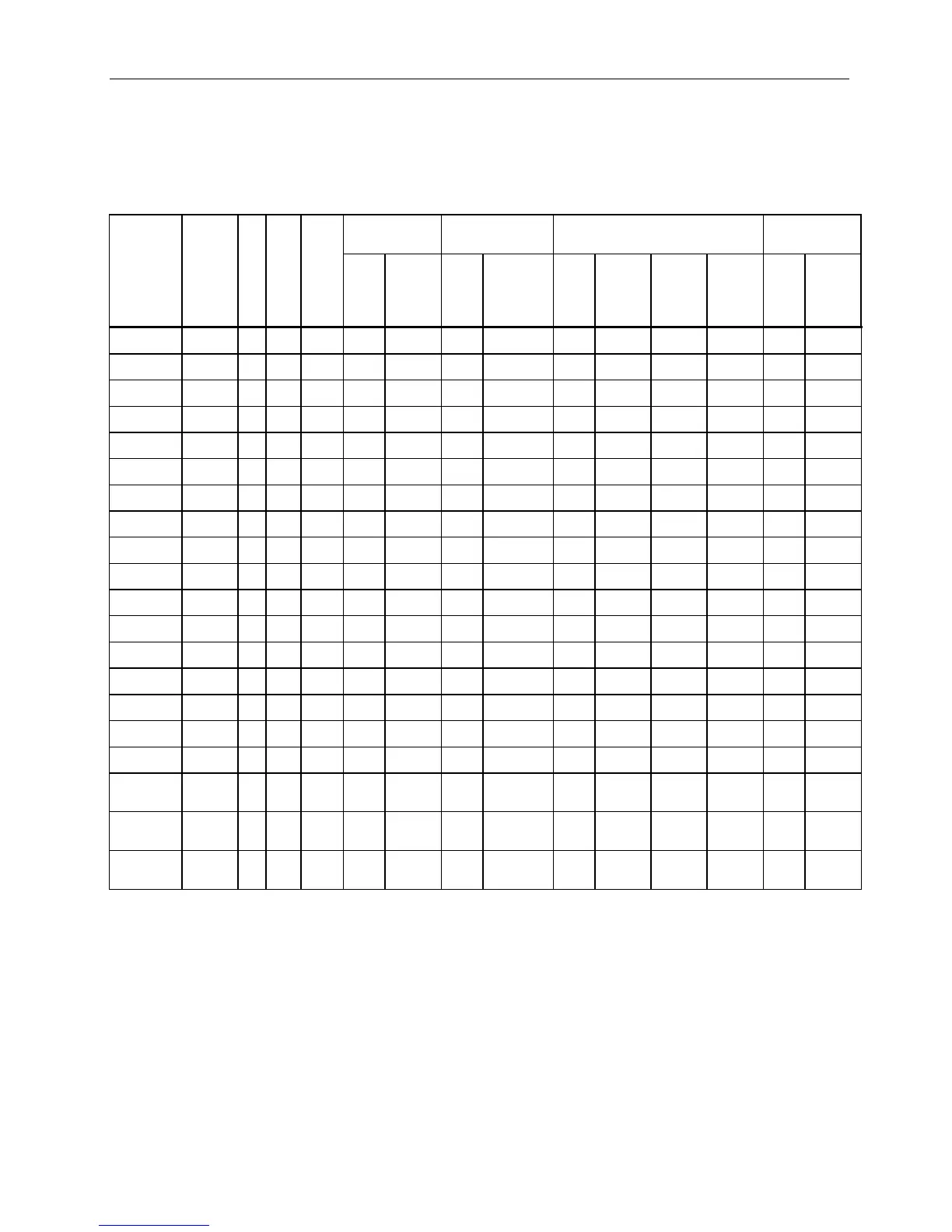

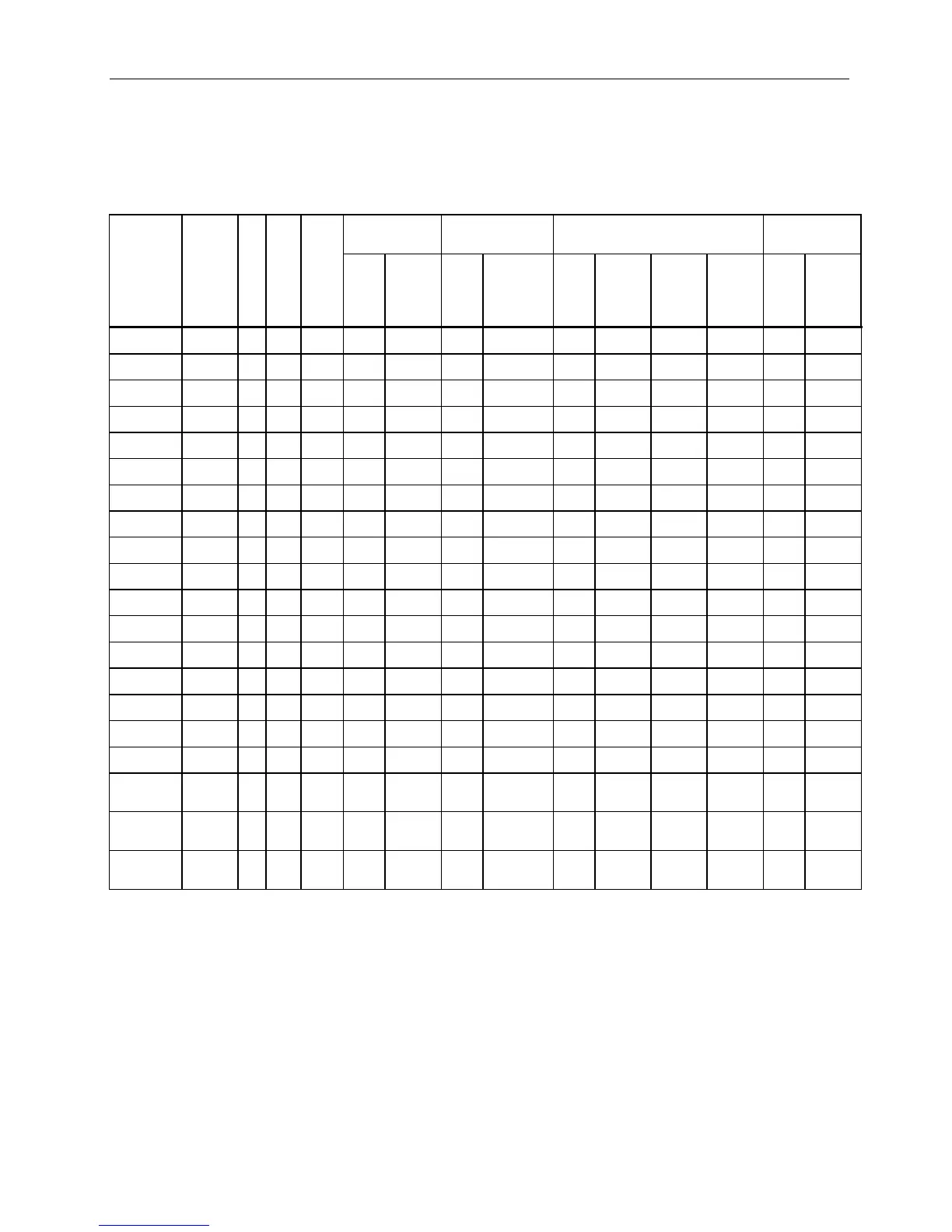

Table 3. Wire Sizes and Tightening Torques for Electronic Bypass System with 380V to 480V Drive.

Circuit Breaker

Disconnect

Switch

Overload Ground Lug

Part

Number

Bypass

Frame

Size

HP kW Amps

Wire

Size *

Torque,

lb-in

(Nm)

Wire

Size *

Torque,

lb-in

(Nm)

Wire

Size *

Torque,

lb-in

(Nm)

Range,

Amps

Max

Backup

Fuse,

Amps

Wire

Size*

Torque,

lb-in

(Nm)

VBE30.5---- A 0.5 0.37 1.1

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

.7 - 1.0

4 14-2 35 (4)

VBE30.7---- A 0.7 0.55 1.6

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

1.1 - 1.6

6 14-2 35 (4)

VBE31.0---- A 1.0 0.75 2.1

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

1.4 - 2.0

8 14-2 35 (4)

VBE31.5---- A 1.5 1.1 3.0

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

2.2 - 3.2

12 14-2 35 (4)

VBE32.0---- A 2.0 1.5 3.4

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

2.8 - 4

16 14-2 35 (4)

VBE33.0---- B 3.0 2.2 4.8

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

3.5 - 5

20 14-2 35 (4)

VBE35.0---- B 5.0 4.0 7.6

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(.8 - 1.2)

7 - 10

40 14-2 35 (4)

VBE37.5---- C 7.5 5.5 11

14-10

Cu

32 (3.6) 18-10

13 - 17

(1.5 - 1.7)

18-14

7 - 10.3

(8 - 1.2)

9 - 12

45 14-2 35 (4)

VBE310---- C 10 7.5 14

14-10

Cu

32 (3.6) 18-10

13 to17

(1.5 - 1.7)

14-10

18 - 22

(2 - 2.5)

11 - 16

60 14-2 35 (4)

VBE315---- C 15 11.0 21

14-10

Cu

20 - 60

(2.2 - 6.8)

14-8

17 - 22

(1.9 - 2.5)

14-10

18 - 22

(2 - 2.5)

17 - 22

80 14-2 35 (4)

VBE320---- C 20 15.0 27

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-8

17 - 22

(1.9 - 2.5)

18-3

27 - 40

(3.1 - 4.5)

22 - 32

125 14-2 35 (4)

VBE325---- D 25 18.5 34

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

28 - 40

150 14-2 35 (4)

VBE330---- D 30 22.0 40

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

28 - 40

150 14-2 35 (4)

VBE340---- D 40 30.0 52

10-1/0

Cu

20 - 60

(2.2 - 6.8)

14-6

22 - 27

(2.5 - 3.1)

18-3

27 - 40

(3.1 - 4.5)

40 - 50

200 14-2 35 (4)

VBE350---- E 50 37.0 65

10-1/0

Cu

20 - 60

(2.2 - 6.8)

12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

57 - 75

300 14-2 35 (4)

VBE360---- E 60 45.0 77

3-3/0

Cu

80 (9) 12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

70 - 90

350 14-2 35 (4)

VBE375---- F 75 55.0 96

3-3/0

Cu

80 (9) 12-1

22 - 27

(2.5 - 3.1)

10-1/0

36 - 53

(4.1 - 6)

80 - 100

400 14-2/0 50 (5.6)

VBE3100---- F 100 75.0 124

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7)

50 - 200 800 14-2/0 50 (5.6)

VBE3125---- F 125 90.0 156

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7)

50 - 200 800 14-2/0 50 (5.6)

VBE3125--

HA

F — 90.0 178

6 - 350

kcmil

Cu

120 - 275

(14 - 31.1)

6 - 350

kcmil

120 - 275

(13.5 - 31.1)

6-3/0

124 - 210

(14 - 23.7)

50 - 200 800 14-2/0 50 (5.6)

* Wire size is AWG unless noted otherwise. Use Copper (Cu) wire that is rated 167°F (75°C) minimum 600 Vac.

14 Siemens Building Technologies

Loading...

Loading...