4 Configuration and Project Engineering

4.1 Creating the project configuration

SINAMICS G120 as a Speed Axis on the S7-1500

V1.0a, Entry ID: 78788716

Copyright Siemens AG 2013 All rights reserved

No. Action Picture

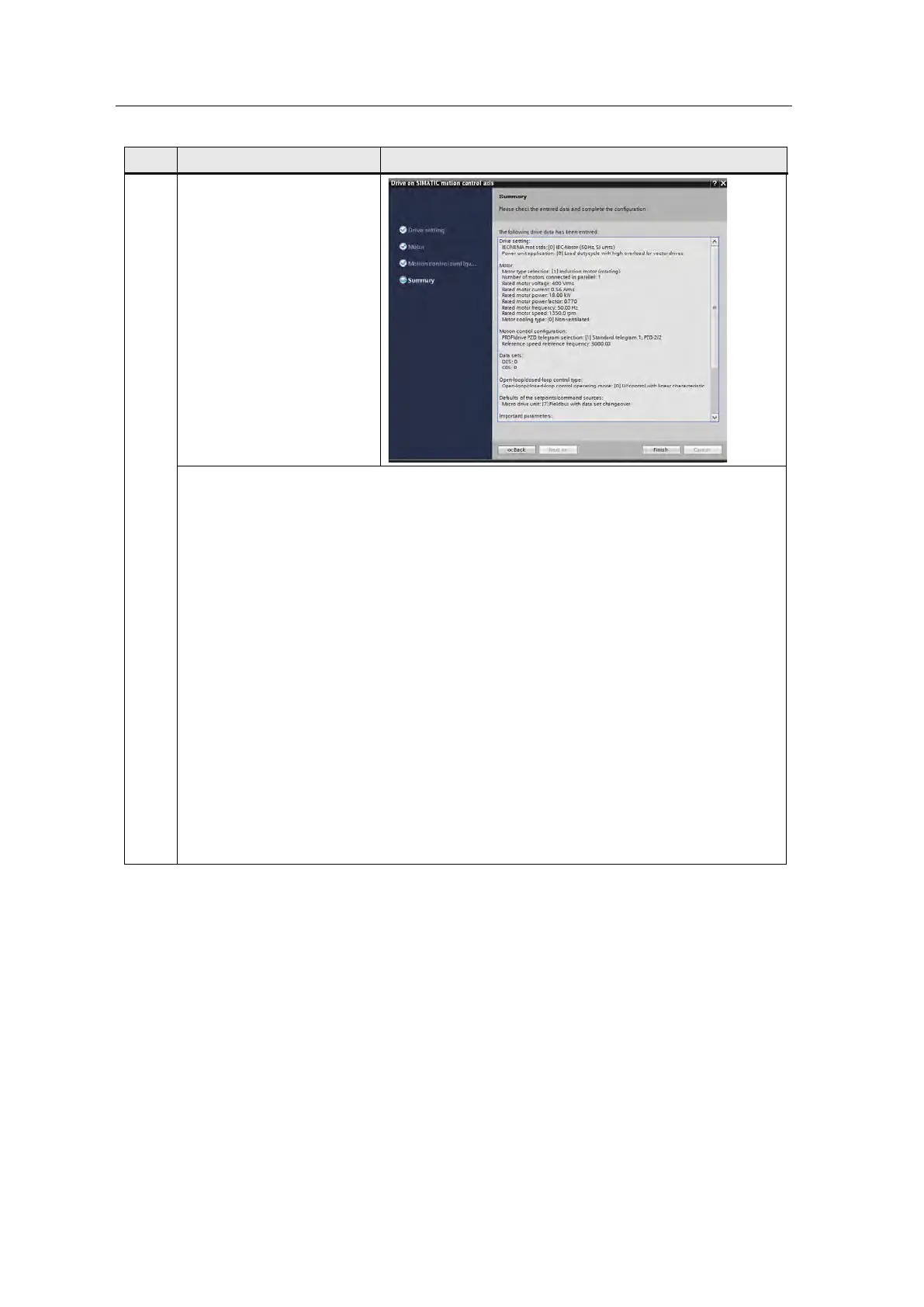

16. The wizard is self-

explanatory.

Enter your motor data here.

Make sure that the same

telegram as in the previous

step is selected at this point.

A summary is displayed

before you complete the

parameterization with

“Finish”. This summary can

be backed up using copy and

paste.

The parameterization in the application example is shown below:

Drive setting:

IEC/NEMA mot stds: [0] IEC-Motor (50 Hz, SI units)

Power unit application: [0] Load duty cycle with high overload for vector drives

Motor:

Motor type selection: [1] Induction motor (rotating)

Number of motors connected in parallel: 1

Rated motor voltage: 400 Vrms

Rated motor current: 0.56 Arms

Rated motor power: 18.00 kW

Rated motor power factor: 0.770

Rated motor frequency: 50.00 Hz

Rated motor speed: 1350.0 rpm

Motor cooling type: [0] Non-ventilated

Motion control configuration:

PROFIdrive PZD telegram selection: [1] Standard telegram 1, PZD-2/2

Reference speed reference frequency: 3000.00

Data sets:

DDS: 0

CDS: 0

Open-loop/closed-loop control type:

Open-loop/closed-loop control operating mode: [0] U/f control with linear characteristic

Defaults of the setpoints/command sources:

Macro drive unit: [7] Fieldbus with data set changeover

Important parameters:

Current limit: 0.84 Arms

Minimum speed: 0.000 rpm

Maximum speed: 1500.000 rpm

Ramp-function generator ramp-up time: 0.000 s

Ramp-function generator ramp-down time: 0.000 s

OFF3 ramp-down time: 0.000 s

Drive functions:

Motor data identification and rotating measurement: [0] Inhibited

Automatic calculation motor/control parameters: [1] Complete calculation

Loading...

Loading...